NeoDen Desktop Reflow Solder

NeoDen Desktop Reflow Solder

NeoDen Desktop Reflow Solder has bypassed the need for a tubular heater, which provides even temperature distribution throughout the reflow oven.

By soldering PCBs in even convection, all components are heated at the same rate.

Temperature can be controlled with extreme accuracy—users can pinpoint heat within 0.2°C.

An internal temperature sensor ensures full control of the heating chamber and can reach optimal temperatures in as little as fifteen minutes.

Specification

| Product Name | NeoDen Desktop Reflow Solder |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 30mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top|3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

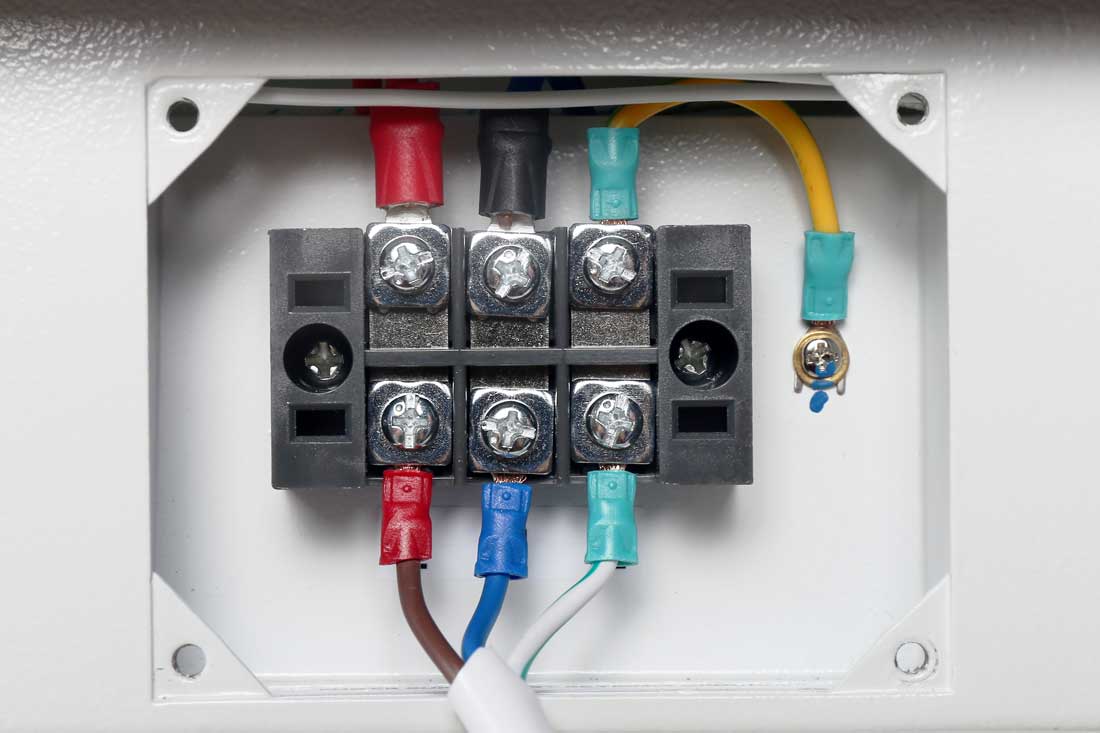

Power Supply Connection

Power supply requirement:110V/220V

Stay away from flammable and explosive

Installation Attentions

♦ Power supply requirement:110V/220V

♦ For desktop reflow oven, should be working on workbench, don’t suggest to use wooden material

♦ The machine should be set in standard SMT workshop, stay away from flammable and explosive if couldn’t meet previous requirements.

♦ Exposed wire harness should be well protected, prohibit to expose at the passage or flue in case of causing any accident.

FAQ

Q1: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry.

If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q2: What is the delivery time for mass production?

A: About 15-30 days.

Q3: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

About us

Factory

Certification

Exhibition

If you need, please feel free to contact us for more information.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.