NeoDen SMD soldering oven reflow station

NeoDen IN12 SMD soldering oven reflow station

Description

Specification

| Product name | NeoDen SMD soldering oven reflow station |

| Model | NeoDen IN12 |

| Heating Zone Quantity | Upper6 / Down6 |

| Cooling Fan | Upper4 |

| Conveyor Speed | 50~600 mm/min |

| Temperature Range | Room temperature~300℃ |

| Temperature Accuracy | 1℃ |

| PCB Temperature Deviation | ±2℃ |

| Max soldering height(mm) | 35mm(includes PCB thickness) |

| Max Soldering Width (PCB Width) | 350mm |

| Length Process Chamber | 1354mm |

| Electricity Supply | AC 220v/single phase |

| Machine Size | L2300mm×W650mm×H1280mm |

| Heat-up Time | 30 min |

| Net Weight | 300Kgs |

Details

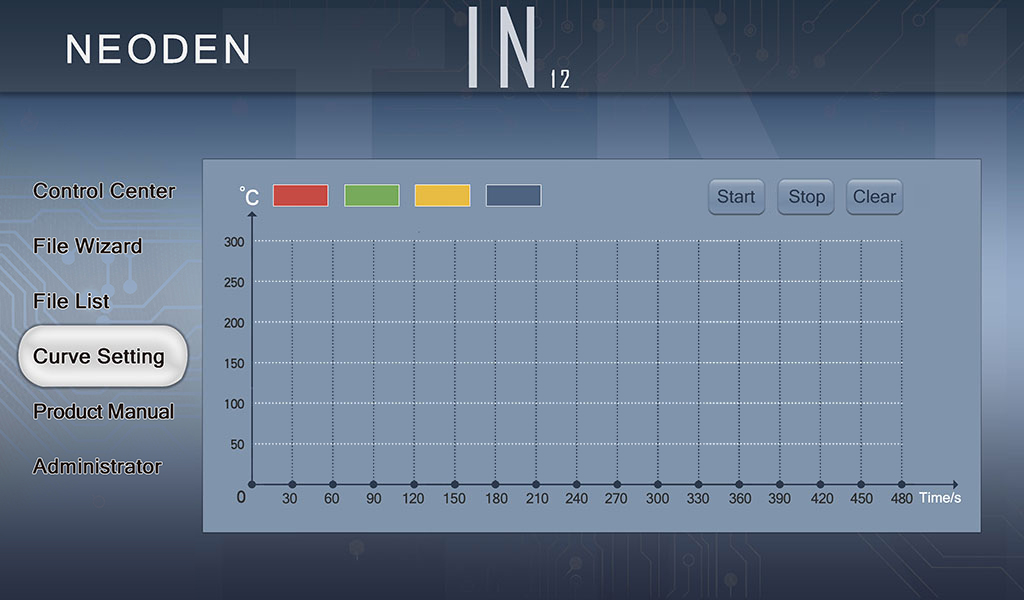

Real-time measurement

1- PCB soldering temperature curve can be displayed based on real-time measurement.

2- Professional and unique 4-way board surface temperature monitoring system, can give timely and comprehensive data feedback in actual operation.

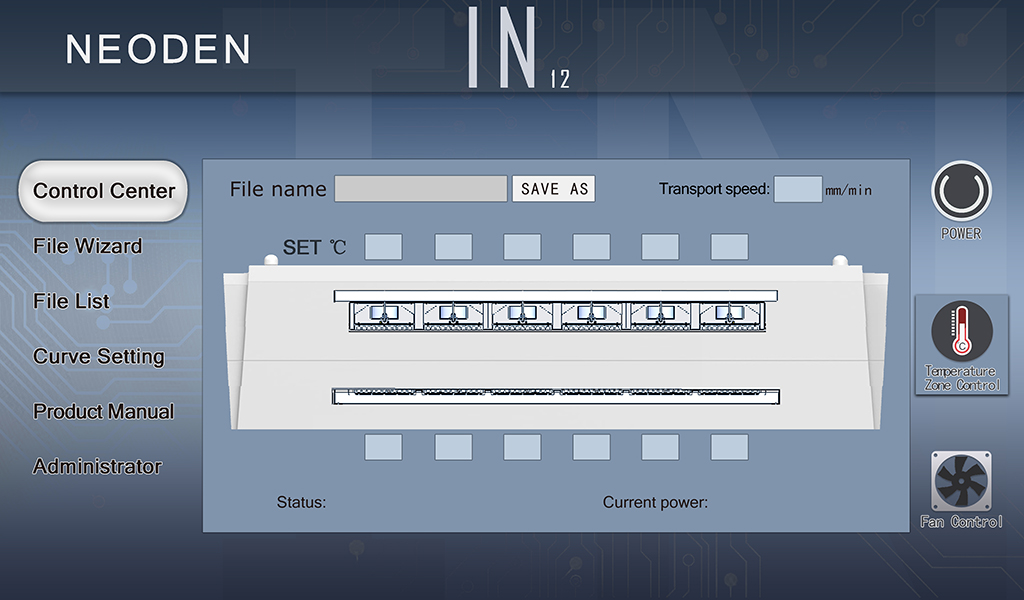

Intelligent control system

1-Heat insulation protection design, the casing temperature can be effectively controlled.

2- Smart control with high sensitivity temperature sensor, the temperature can be effectively stabilized.

3-Intelligent, the custom developed intelligent control system, easy to use and powerful.

Energy saving & Eco-friendly

1-Built-in welding smoke filtering system, effective filtration of harmful gases.

2-Energy saving, low power consumption, low power supply requirements, the ordinary civil electricity can meet the use.

3-The internal thermostat is made of stainless steel, which is environment friendly and has no peculiar smell.

Attentive design

1-Hidden screen design is convenient for transportation, easy to use.

2-The upper temperature cover is automatically limited once opened, effectively ensuring the personal safety for the operators.

Provide one-stop SMT assembly production line

Related products

FAQ

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: Is it hard to use these machines?

A: No,not hard at all.For our previous clients, at most 2 days is enough to learn to operate the machines.

Q3: Can we customize the machine?

A: Of course. All of our machines can be customized.

About us

Exhibition

Certification

Factory

If you need, please feel free to contact us for more information.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.