Reflow Oven Machine

Reflow Oven Machine

Specification

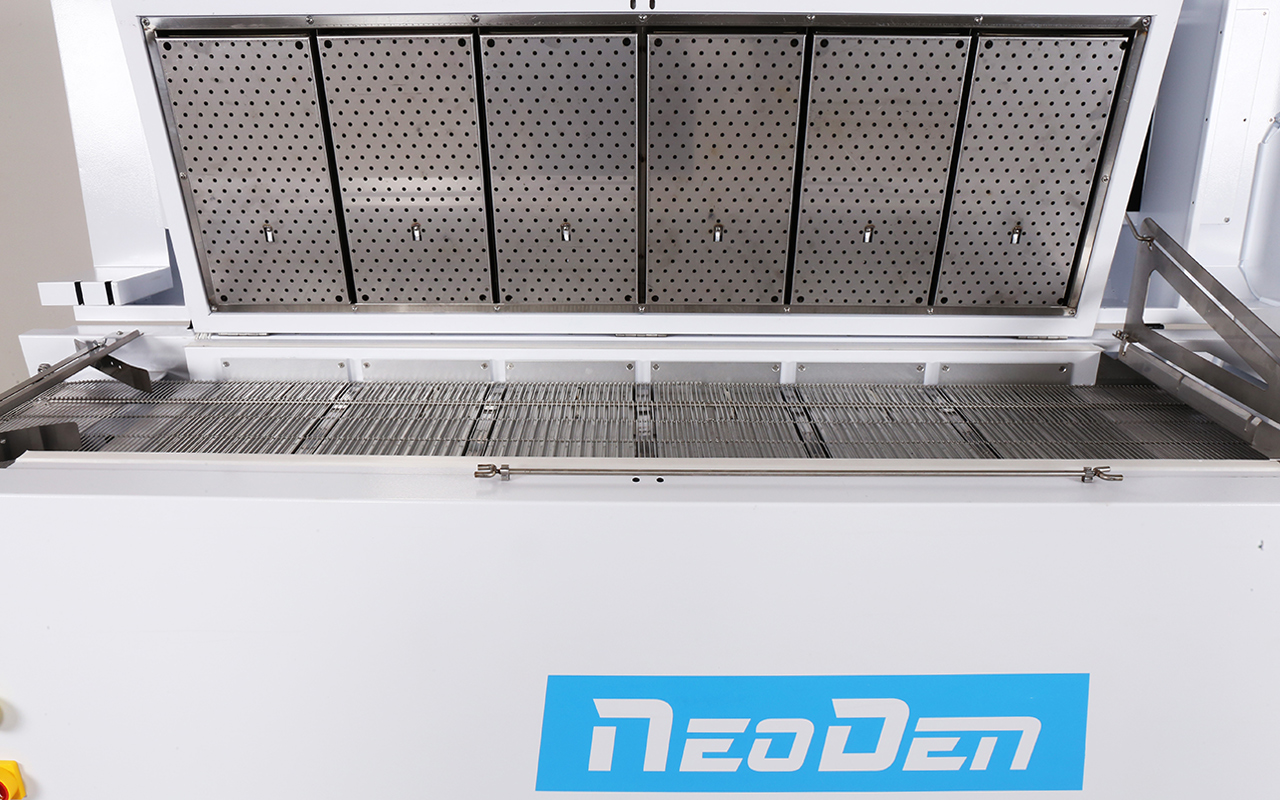

1. The mesh sprocket made of high-precision profile technology and the unique support structure can effectively reduce the vibration of the PCB in the reflow zones, and easily cope with the welding of small size components such as 0201 and complex chips such as BGA/QFP/QFN.

2. The cooling zone with independent circulating air design completely isolates the influence of the external environment on the internal temperature chambers.

3. The control system adopts imported chips, and the temperature control accuracy reaches ±0.5%.

Feature

Product name: Reflow Oven Machine

Cooling fan: Upper4

Conveyor speed: 50~600 mm/min

Temperature range: Room temperature~300℃

PCB temperature deviation: ±2℃

Max soldering height(mm): 35mm (includes PCB thickness)

Max soldering width (PCB Width): 350mm

Length process chamber: 1354mm

Electricity supply: AC 220v/single phase

Machine size: L2300mm×W650mm×H1280mm

Heat-up time: 30 min

Net weight: 300Kgs

Details

12 temperature zones

High temperature control accuracy

Uniform temperature distribution in the thermal compensation area

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power consumption, low power supply requirements

Operation panel

Hidden screen design

convenient for transportation

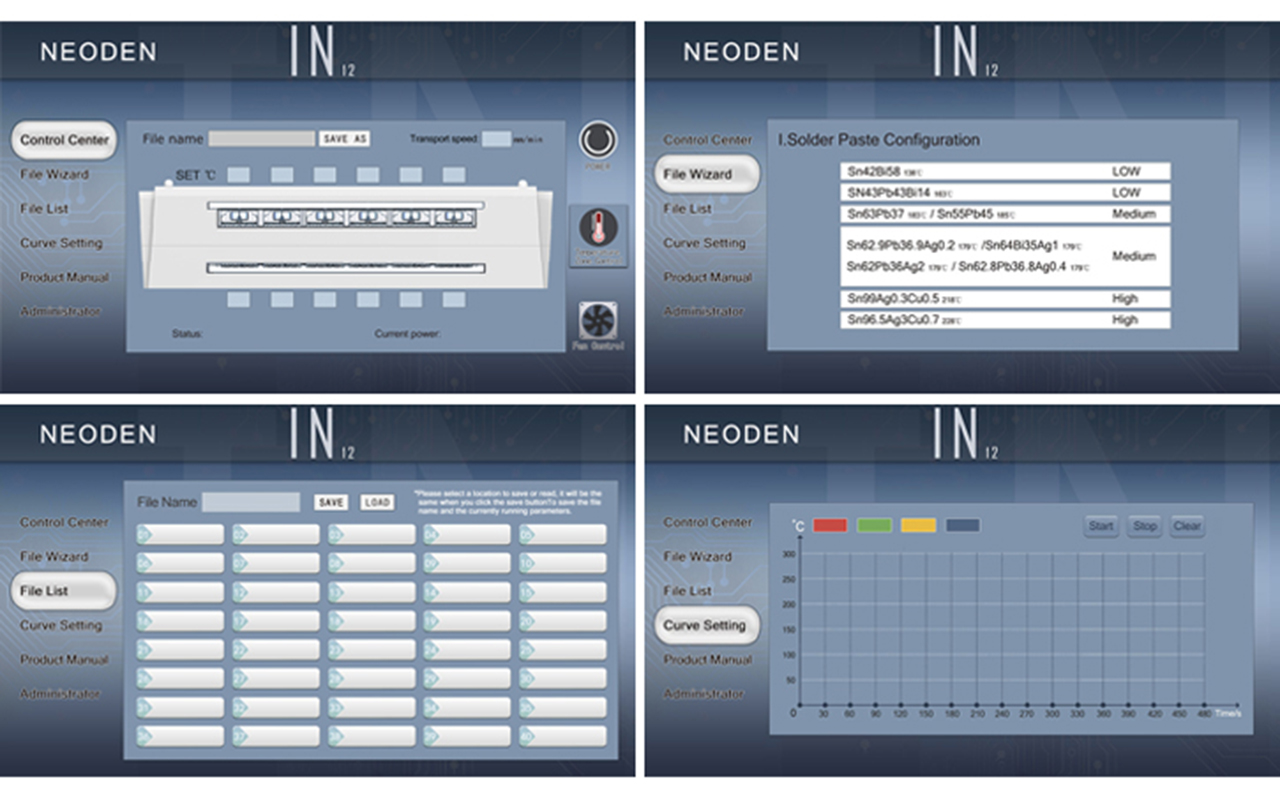

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

About NeoDen IN12

SMT reflow soldering equipment technology has experienced different forms of development process, such as plate radiation heating, quartz infrared tube heating, infrared hot air heating, forced hot air heating, forced hot air heating and nitrogen protection.

The increased requirements of the reflow oven cooling process have also contributed to the development of the SMT reflow soldering equipment cooling zone, from room temperature natural cooling, air cooling to water cooling system designed for lead-free welding.

FAQ

Q1: What about the lead time for mass production?

A: 15-30 working days for mass production.

It depends on your quantity, and we will try our best to meet your needs.

Q2: How your quality guarantee?

A: We have 100% quality guarantee to customers. We will be responsible for any quality problem.

Q3: Can we visit your factory before place the order?

A: Yes, very welcome that must be nice to set up good relationship for business.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.