Documents required for stencil production

Provide the original PCB file, provide the Gerber file, at least provide the SMD layer, i.e. GTP, GBP. if there is no SMD layer, you need to provide the soldermask layer (gbs and gts), the line layer (gtl and gbl), the character layer (gto and gbo), the drilling layer (drl)

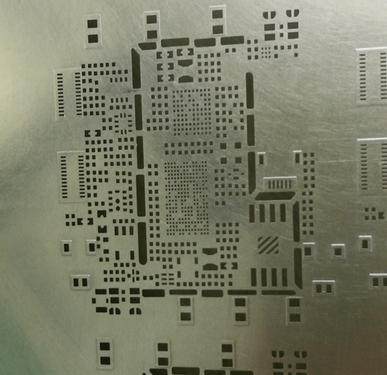

Stencil is a necessary tool for solder paste printing, stencil is the PCB pad template, squeegee will be solder paste through the stencil openings printed on the pcb pad, for the subsequent SMT machine patch and reflow oven soldering pad, most of the current market is a laser open stencil, stencil hole wall is smoother, to ensure that the solder paste is better leakage. The stencil is shown in the figure below

The following requirements should be followed to open the stencil

1. Provide relevant documents to the stencil supplier.

2. The size of the stencil should be decided according to the size structure of the printing machine and the specification of the pcb product.

3. Mark the thickness of the stencil, production date, material and so on.

4. Stencil openings are generally less than a quarter of the pad.

5. Stencil aperture into the board flow direction to be unified with the mounter.

Stencil production is completed, acceptance-related considerations

1. Whether the stencil thickness meets the requirements.

2. Whether the size of the stencil is correct.

3. Whether the flatness of stencil is up to standard.

4. Whether the position and number of stencil openings are consistent with the documents.

The quality of stencil production directly affects the paste printing is uniform, whether flat and full, paste flatness, whether offset and thickness will determine the quality of welding problems, so stencil acceptance needs to be carefully checked, can not appear half a point of error.

Features of NeoDen FP2636 Stencil Printer

1. T screw rod regulating handle, ensure adjustment accuracy and levelness of PCB fixed plane, minimum lead pitch achieved 1mm.

2. Adjustable rubber footing, ensure the flatness while operating.

3. Letter mark for each regulating handle, better and easier to operate.

4. Rulers of stencil fixed frame for reference lines, ensure the levelness between stencil and PCB.

5. Straight damping shaft, ensure the stencil fixed frame can be fastened at random angles, to improve convenience while operating.

Post time: Jan-18-2024