Factory directly Furnace For Reflow Process - Soldering Oven – Neoden

Factory directly Furnace For Reflow Process - Soldering Oven – Neoden Detail:

Soldering oven NeoDen IN6 is a newly designed and manufactured reflow oven by NeoDen Tech.

NeoDen IN6 heats insulation protection design, the casing temperature can be controlled within 40℃.

Household power supply, convenient and practical.

NeoDen IN6 is a desktop soldering machine with excellent soldering performance. ESD tray, easy to collect PCB after reflowing, convenient for R&D and prototype. Japan NSK hot-air motor bearings and Swiss heating wire, durable and stable.

Specifications

| Product Name | Soldering oven NeoDen IN6 |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/down3 |

| Conveyor speed | 5 – 30 cm/min (2 – 12 inch/min) |

| Standard Max Height | 30mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Spotlights

6 zones design, light and compact. Smart control with high sensitivity temperature sensor, the temperature can be stabilized within + 0.2℃. Original high-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature difference is less than 2℃.

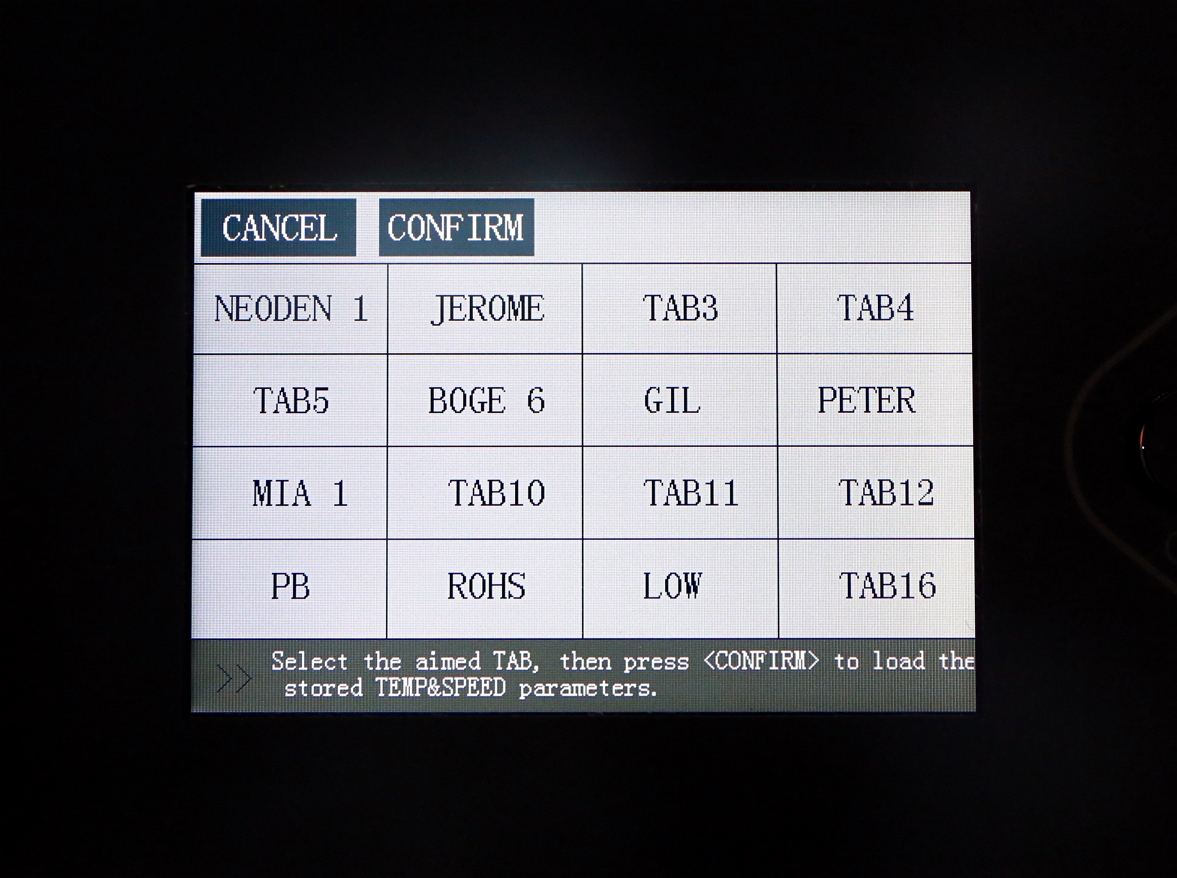

2. 16 working files can be saved

Several working files can be stored, freely switch between Celsius and Fahrenheit, flexible and easy to understand.

PCB soldering temperature curve can be displayed based on real-time measurement

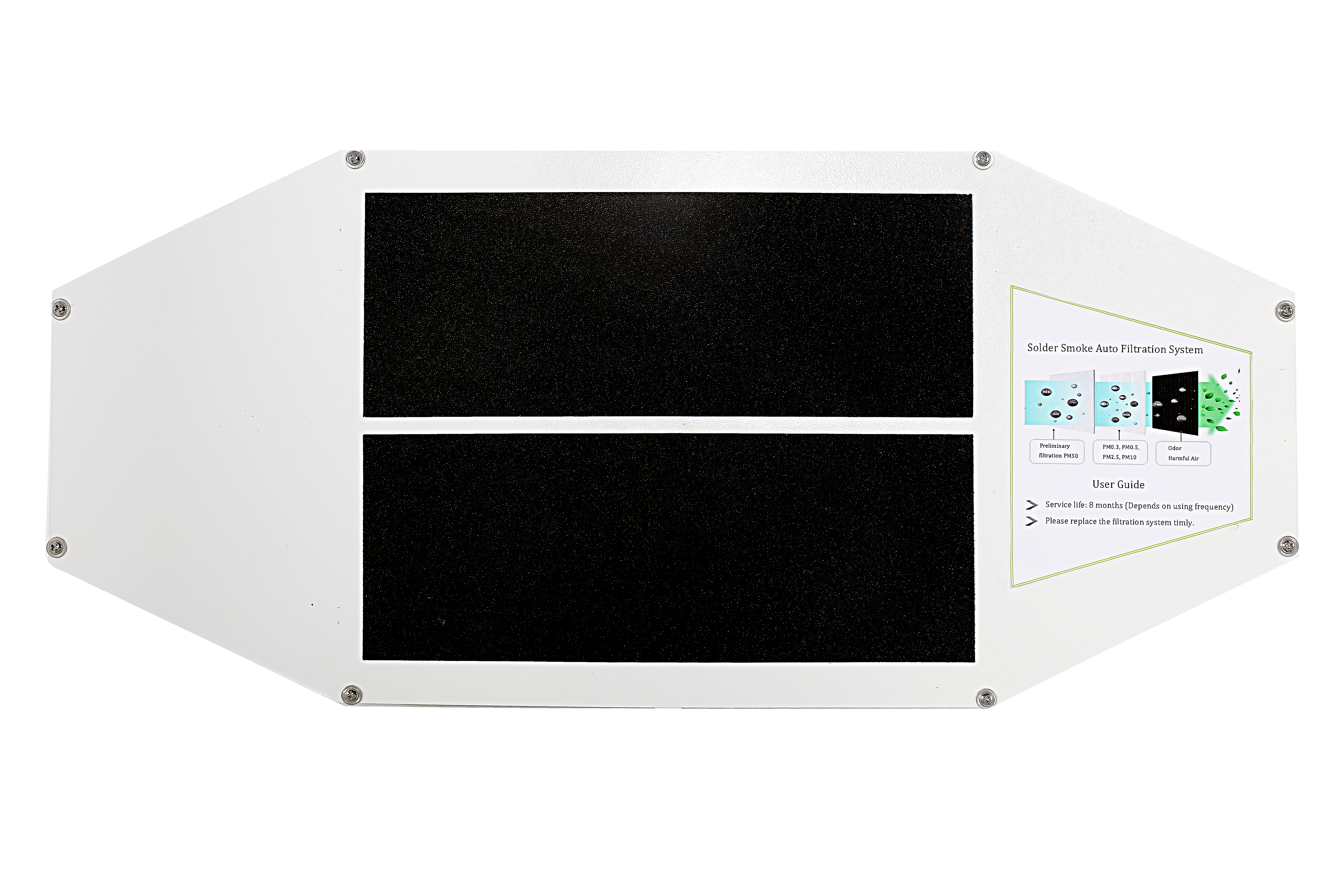

3. Welding smoke filtering system

Original built-in soldering smoke filtering system, elegant appearance and eco-friendly.

Our Service

1. Provide video tutorial after purchasing the product

2. 24-hour online support

3. Professional after-sales technical team

4. Free broken parts(Within 1 Year warranty)

Provide one-stop SMT assembly production line

Related products

|

|

|

| Stencil printer FP2636 | SMT pick and place machine NeoDen4 | Automatic conveyor J12 |

Certificate

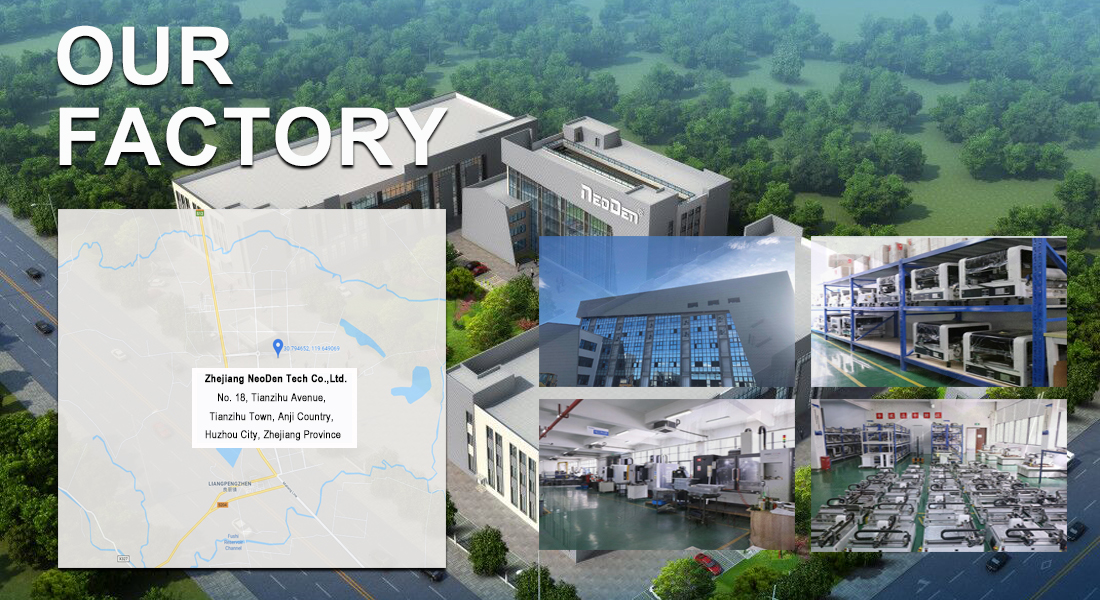

Factory

Hangzhou NeoDen Technology Co., LTD., founded in 2010, in this decade, we independently developed NeoDen4, NeoDen IN6, NeoDen K1830, NeoDen FP2636 and other SMT products, which sold well all over the world. So far, we have sold more than 10,000pcs machines and exported them to over 130 countries around the world, establishing a good reputation in the market. In our global Ecosystem, we collaborate with our best partner to deliver a more closing sales service, high professional and efficient technical support.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere.

FAQ

Q1: Does our machine need air supply?

A: We have vacuum pump inside machine , no need air supply .

Q2: What’s the way of shipping?

A: These are all heavy machines; we suggest you use cargo ship. But components for mending the machines, air transportation would be fine.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for Factory directly Furnace For Reflow Process - Soldering Oven – Neoden , The product will supply to all over the world, such as: Georgia, Macedonia, Florence, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.