Factory Free sample Pcb Component Placement Machine - NeoDen10 Automatic Pick and Place Machine – Neoden

Factory Free sample Pcb Component Placement Machine - NeoDen10 Automatic Pick and Place Machine – Neoden Detail:

NeoDen10 Automatic Pick and Place Machine video

NeoDen10 Automatic Pick and Place Machine

Description

Product name: NeoDen10 Automatic Pick and Place Machine

Model: NeoDen 10

IC Tray Capacity: 20

Smallest Component size: 0201 (electronic feeder)

Applicable Components: 0201, Fine-pitch IC, Led Component, Diode, Triode

Component Height Maximum: 16mm

Applicable PCB size: 500mm*300mm (1500 optinal)

Power Supply: 220V, 50Hz (convertible to 110V)

Air source: 0.6MPa

N.W.: 1100Kgs

Product Detail

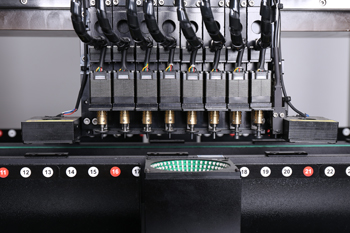

8 heads with Vision enabled

Rotation: +/-180 (360)

High speed repeatable placement accuracy

66 Reel tape feeders

Be calibrated automatically and promptly

Ensure easy operation and high efficiency

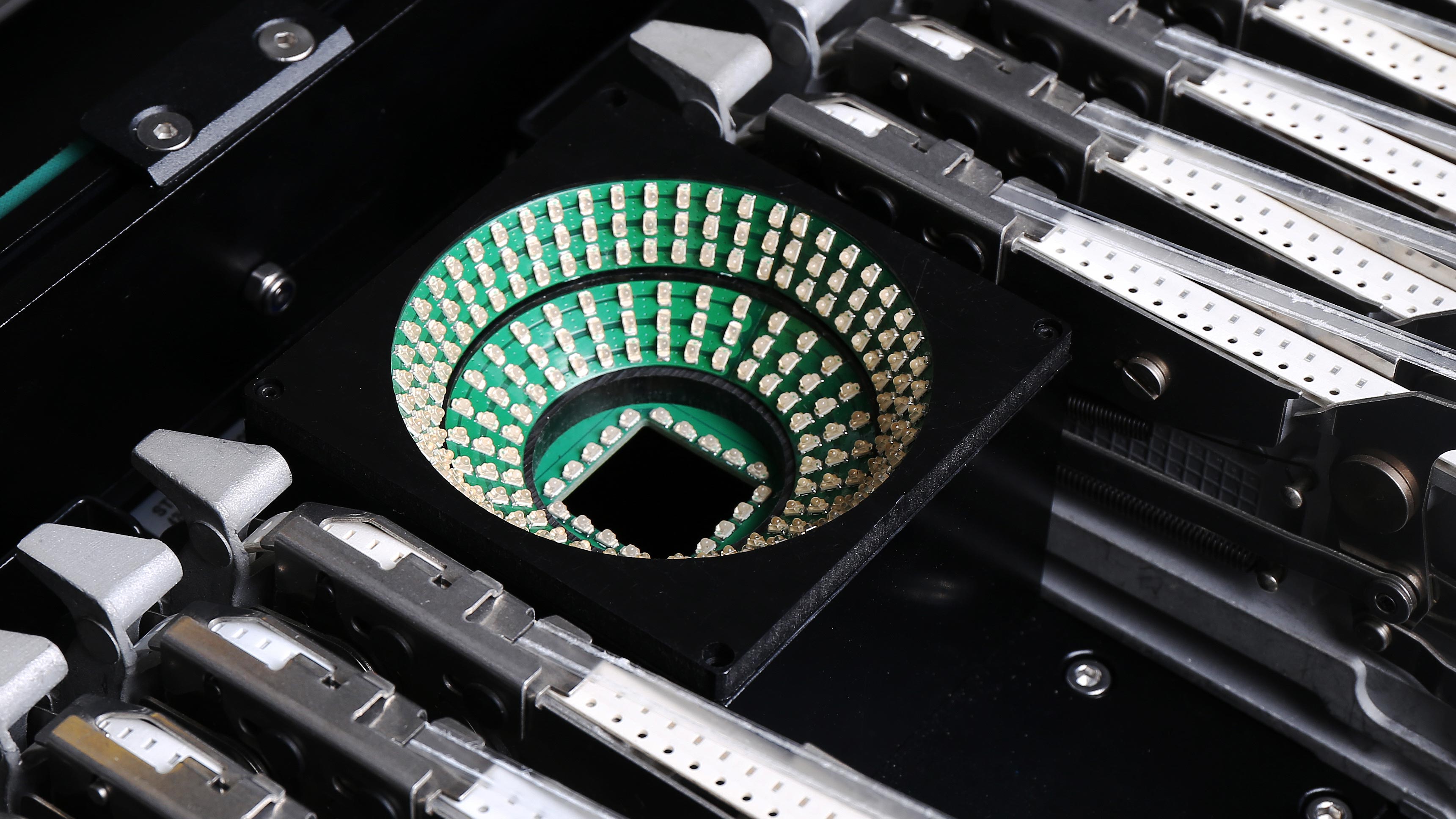

Double mark cameras

Better calibration

Improves the overall speed of the machine

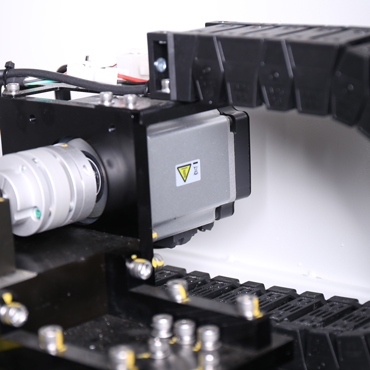

Drive Motor

Panasonic Servo Motor A6

Make the machine to function more accurate

High-definition display

Display size: 12 inch

Makes the machine more convenient to use

Warning light

Triple color of light

Beautiful and elegant indicator design

Description

1. Equips double mark camera + double side high precision flying camera ensure high speed and accuracy, real speed up to 13,000 CPH.

Using the real-time calculation algorithm without virtual parameters for speed counting.

2. The magnetic linear encoder system real-time monitor the machine’s accuracy and enables machine to correct error parameter automatically.

3. 8 independent heads with fully closed-loop control system support all 8mm feeder pick up simultaneously,speed up to 13,000 CPH.

4. Mouting height Up to 16mm, precision design and stable performance

Our Service

Provide product instructions

YouTube video tutorials

Experienced after-sales technicians, 24 hours online service

With our own manufactory and more than 10 years of experience in SMT industry

We can provide customers with the most cost-effective products.

Comparison of similar products

If you need, please feel free to contact us for more information.

FAQ

Q1: How can I place an order?

A: You can contact any of our sales person for an order.

Please provide the details of your requirements as clear as possible.

So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.

Q2: How far is your factory from the airport and train station?

A: From airport about 2 hours by car, and from train station about 30 minutes.

We can pick up you.

Q3: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

About us

Factory

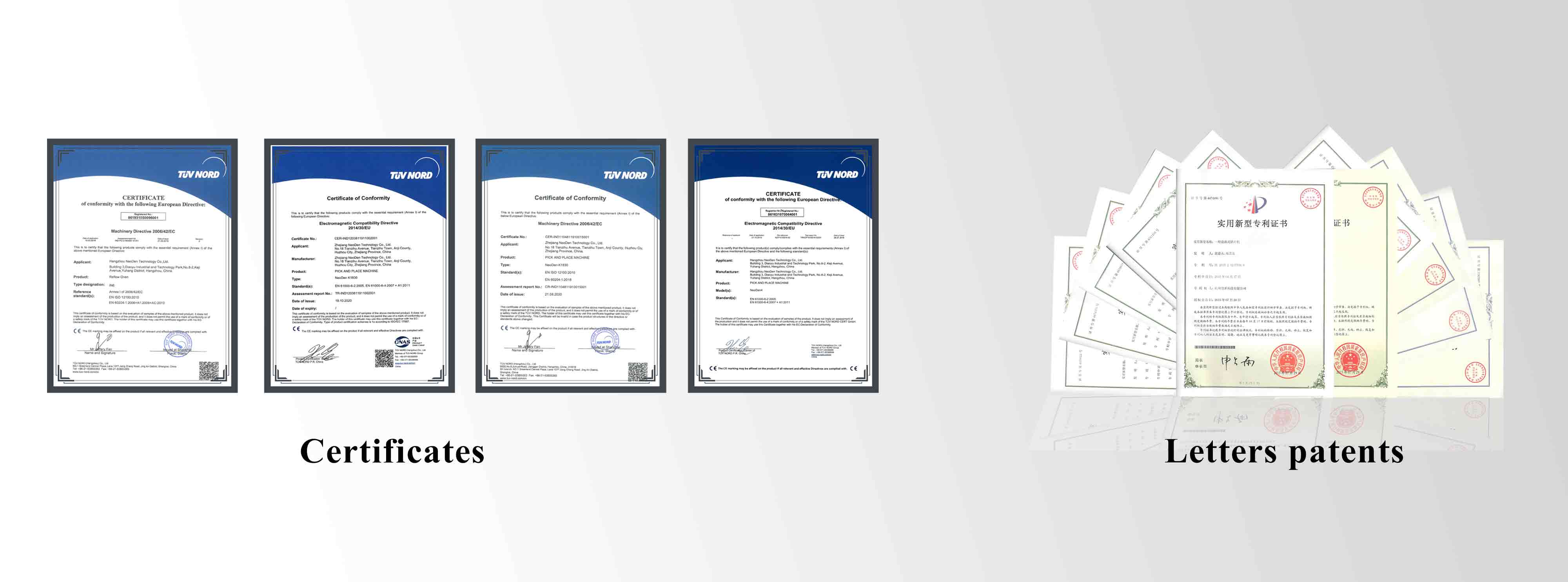

Certification

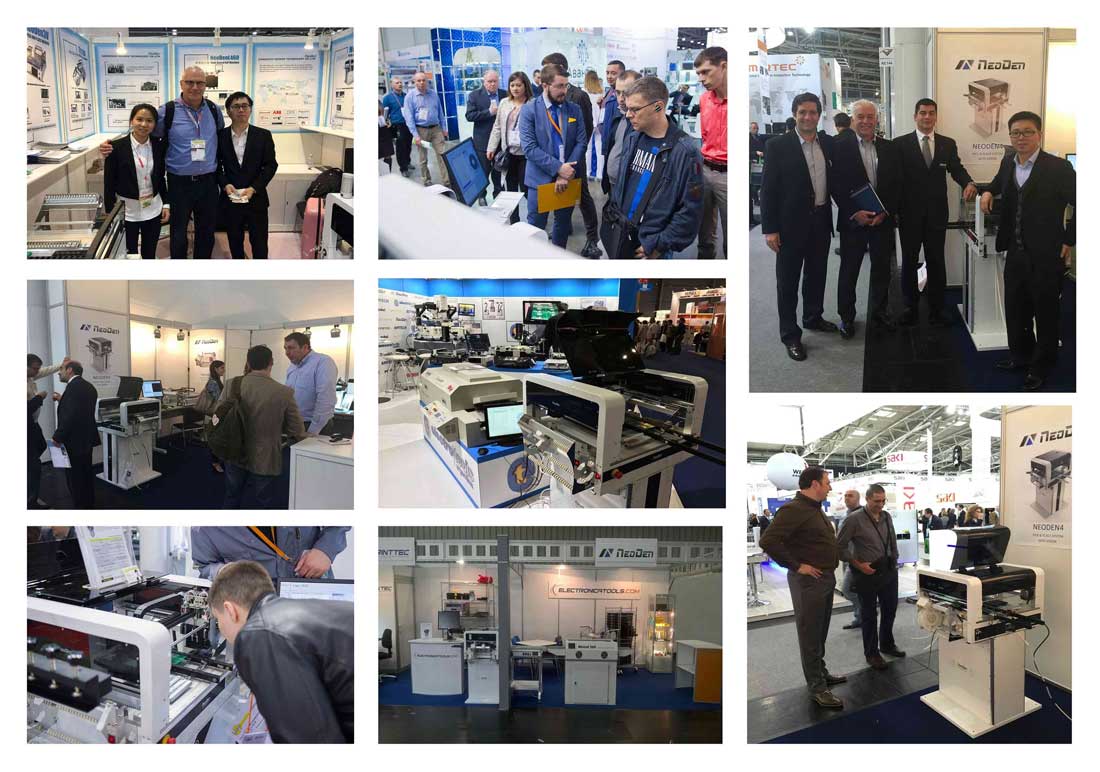

Exhibition

If you need, please feel free to contact us for more information.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

As for competitive selling prices, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we are the lowest around for Factory Free sample Pcb Component Placement Machine - NeoDen10 Automatic Pick and Place Machine – Neoden , The product will supply to all over the world, such as: Namibia, Toronto, Florence, What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.