Factory made hot-sale Smd Pick And Place Ccd - NeoDen4 pick and place desktop machine – Neoden

Factory made hot-sale Smd Pick And Place Ccd - NeoDen4 pick and place desktop machine – Neoden Detail:

NeoDen4 pick and place desktop machine Video

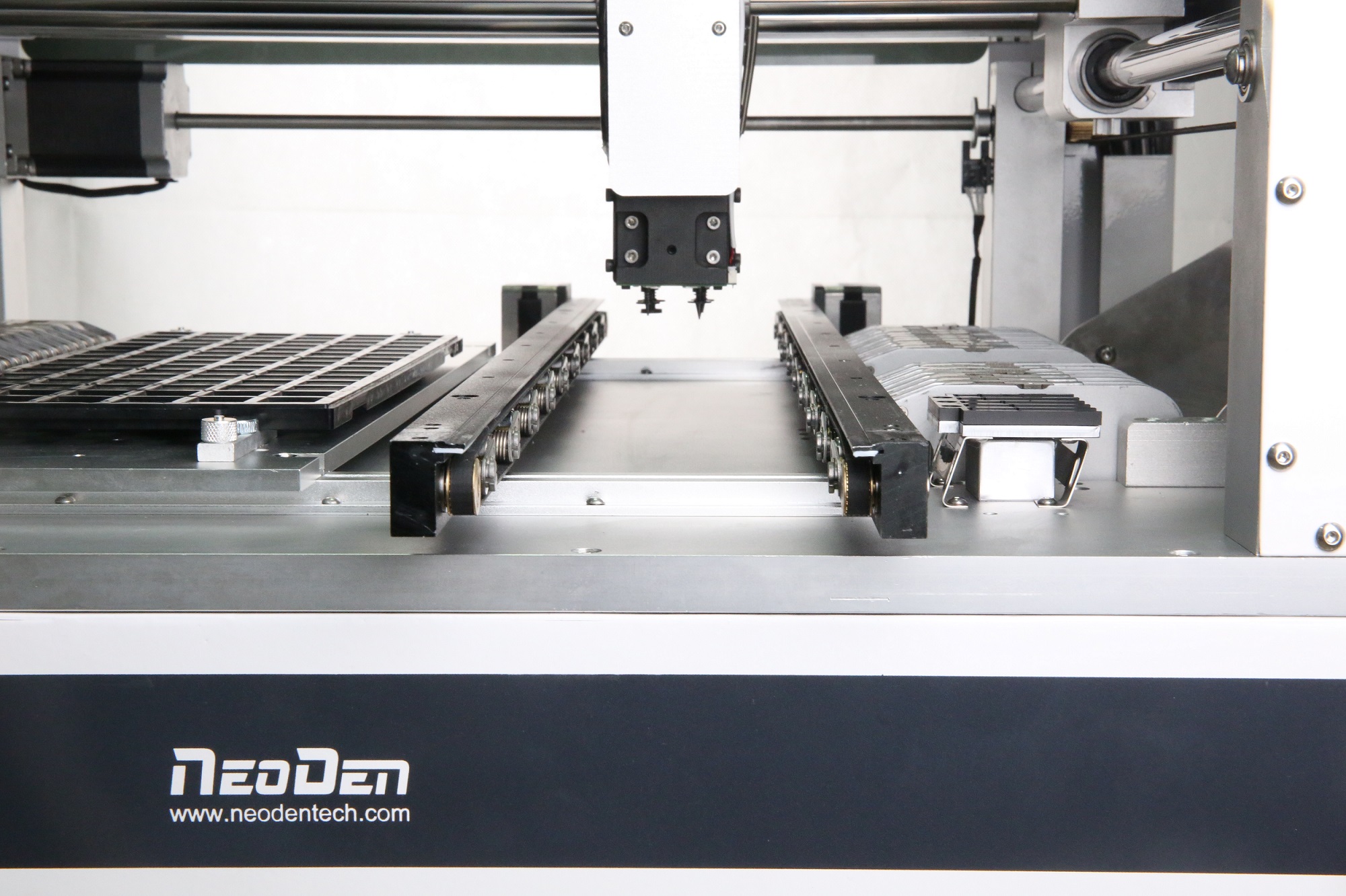

NeoDen4 pick and place desktop machine

Specification

Product name: NeoDen4 pick and place desktop machine

Model: NeoDen4

Machine Style: Single gantry with 4 heads

Placement Rate: 4000 CPH

External Dimension: L 870×W 680×H 480mm

Max applicable PCB: 290mm*1200mm

Feeders: 48pcs

Average working power: 220V/160W

Component Range: Smallest Size: 0201, Biggest Size: TQFP240, Max Height: 5mm

Details

On-line dual rails

Deliver the finished board.

The rail system allows automatic feeding of PCBs.

Automatic alignment of the board with the camera.

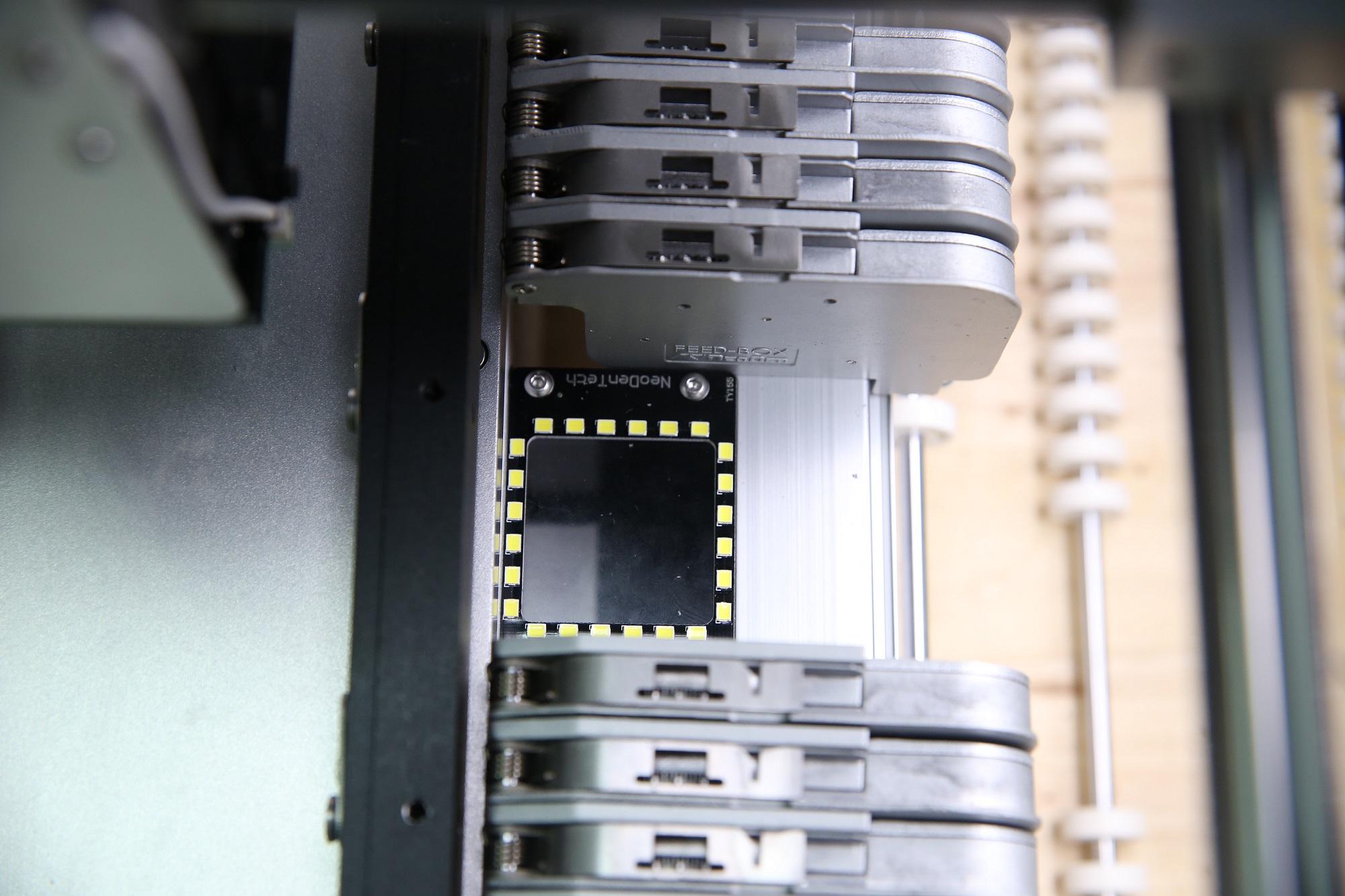

Vision system

Precisely aligned to the nozzles.

High-precision, two-camera vision system.

The cameras are made by Micron Technology.

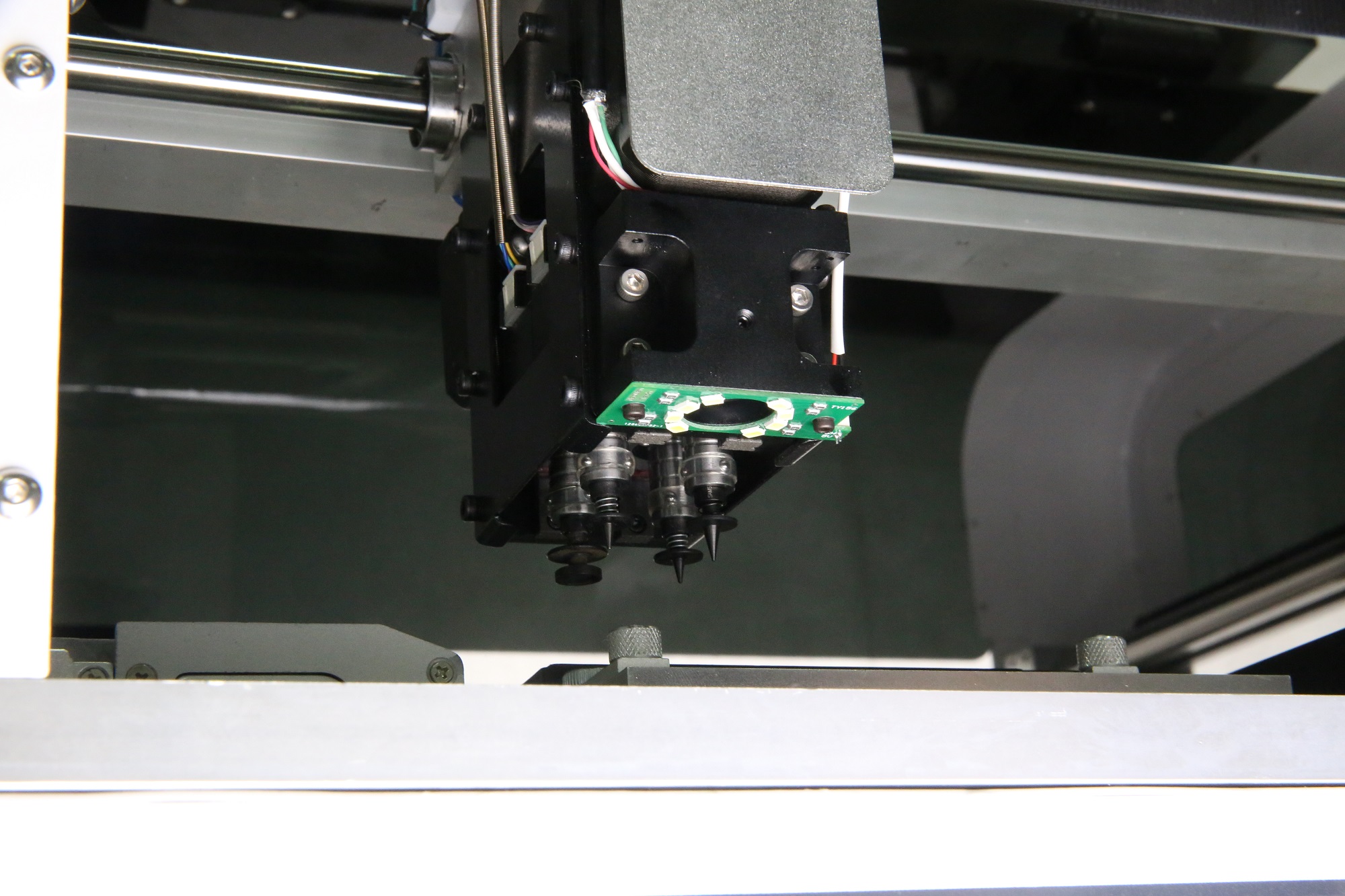

Four high precision nozzles

Any size nozzle can be installed in the head

Single machine can handle all of the necessary components

Electric tape-and-reel feeders

Accommodate up to 48 8mm tape-and-reel feeders

Any size feeder (8, 12, 16 and 24mm) can be installed in the machine

Accessories

| 1) Pick and Place Machine NeoDen4 | 1pc | 7)Allen wrench Set | 5pcs |

| 2) Nozzle | 6pcs | 8)Tool Box | 1pc |

| 3) 8G Flash Drive | 1pc | 9)Reel holder stand | 1pc |

| 4) Power Cord(5M) | 1pc | 10)Vibration Feeder | 1pc |

| 5) Video training course | 1pc | 11)Rail Extension Parts | 4pcs |

| 6) Double Sided Adhesive Tape | 2pcs | 12)User Manual | 1pc |

Quality Control

We have QC person stay on the production lines do to the inspection.

All products must have been inspected before delivery. we do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

Packing

Related products

|

|

|

| Automatic conveyor J12 | Reflow Oven IN6 |

Comparison of similar products

If you need, please feel free to contact us for more information.

FAQ

Q1: Can we be your agent?

A: Yes, welcome to cooperation with this. We have big promotion in the market now. For the details please contact with our overseas manager.

Q2: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.

Q3: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

About us

If you need, please feel free to contact us for more information.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

Our intention is usually to satisfy our buyers by offering golden provider, great rate and good quality for Factory made hot-sale Smd Pick And Place Ccd - NeoDen4 pick and place desktop machine – Neoden , The product will supply to all over the world, such as: Jordan, Brisbane, Canada, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!