High Quality Robotic Pick And Place - SMD component mounting machine, SMT machine – Neoden

High Quality Robotic Pick And Place - SMD component mounting machine, SMT machine – Neoden Detail:

NeoDen K1830 SMD component mounting machine video

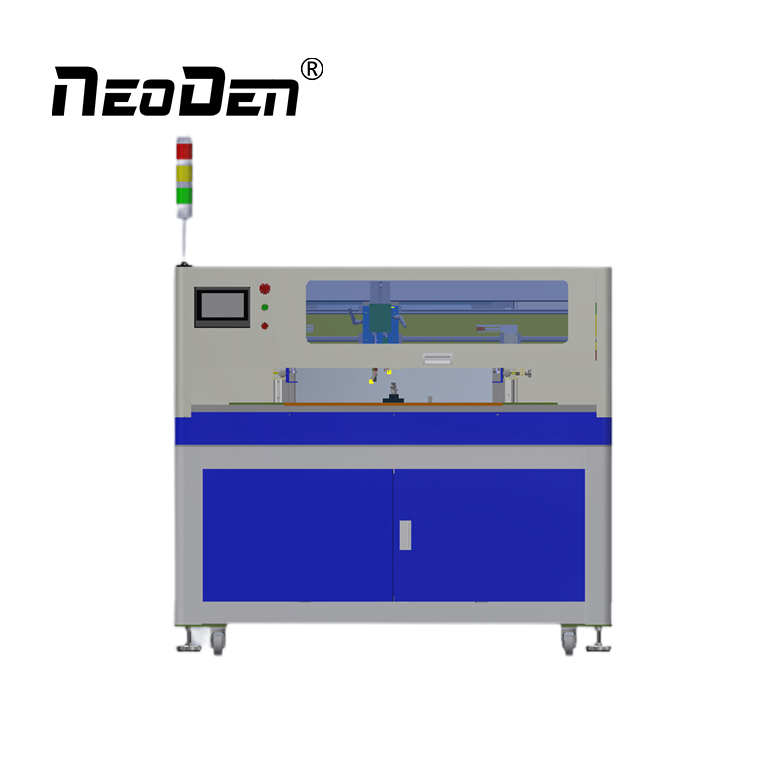

NeoDen K1830 SMD component mounting machine

Features

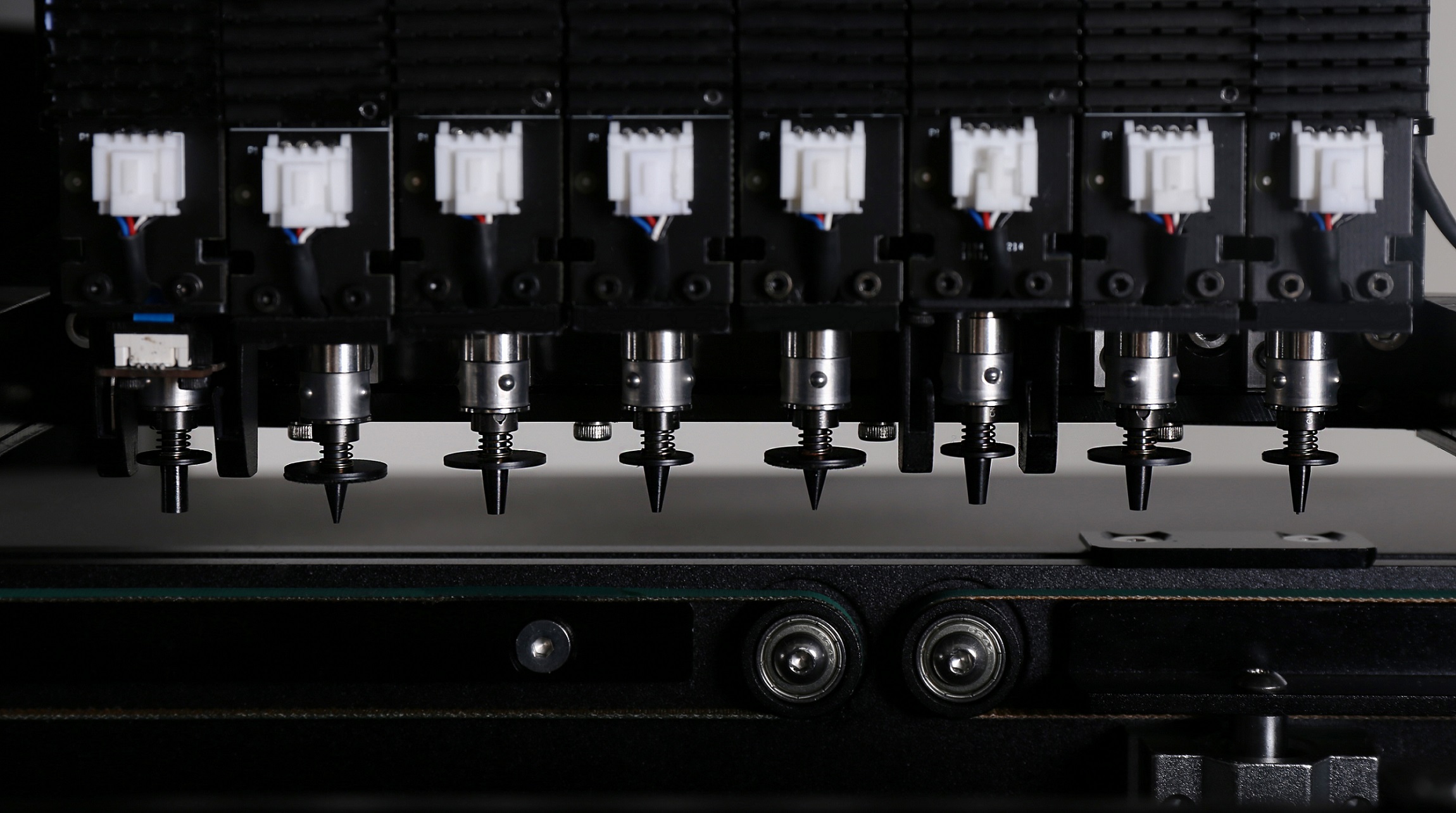

Head

8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed

System

Machine runs on highly stable and secure Linux operating system

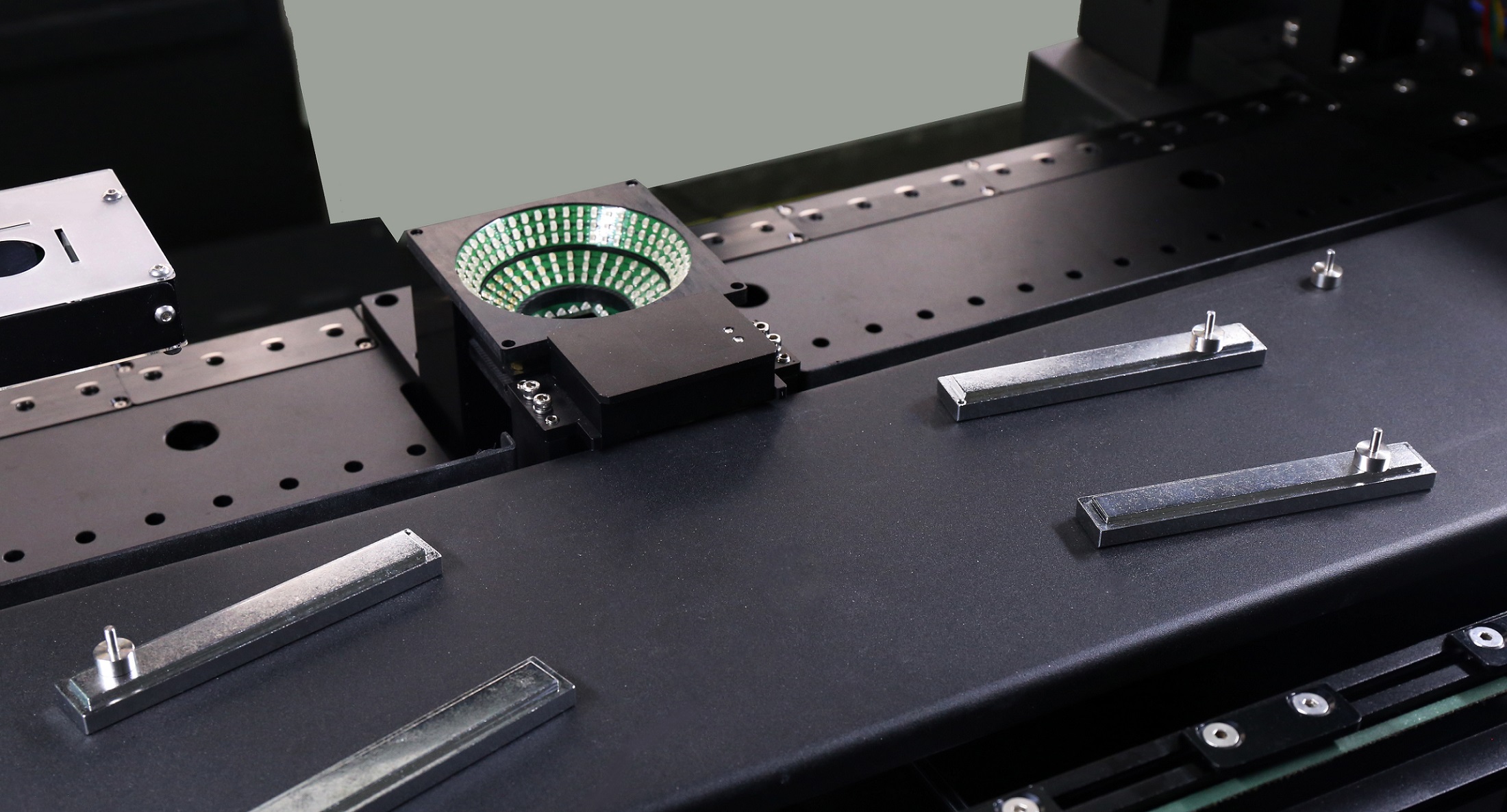

Camera

Double mark cameras to reach at extreme end feeders for better calibration

Interface

Ethernet communication interface for all internal signal travel makes the machine to perform more

stable and flexible

Feeder

Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy

operation and high efficiency

Calibrate

PCB location can be calibrated automatically and promptly,based on the correct and specific placement

request

Product Detail

1-8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed.

2-Machine runs on highly stable and secure Linux operating system.

1-Double mark cameras to reach at extreme end feeders for better calibration.

2-High resolution and high speed component camera system improves the overall speed of the machine.

1-Closed loop Servo control system with feedback makes the machine to function more accurate.

2-Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy operation and high efficiency.

Description

| Product name | NeoDen K1830 SMD component mounting machine |

| Nozzle Q’ty | 8 |

| Reel Tape Feeder Q’ty(Max) | 66 (Electric / Pneumatic) |

| IC Tray Feeder Q’ty | 10 (In Succession) |

| Max PCB size | 540*300mm(In Single Step) |

| Smallest Component Size | 0201(Electric Feeder Available) |

| IC Packages | QFP, SSOP, QFN, BGA |

| Placement accuracy | 0.01mm |

| Max Component Height | 18mm |

| Max Placement Speed | 16,000CPH |

| Component Recognition | High Resolution Flying Vision Camera System |

| PCB Fiducial Recognition | High Precision Mark Camera |

| PCB Loading | Synchronized 3 Stages Internal Conveyor system |

| PCB Transfer Direction | Left→Right |

| Air Supply | >0.6MPa |

| Power | 500W |

| Voltage | 220V/50HZ & 110V/60HZ |

| Net Weight | 280kgs |

| Gross Weight | 360kgs |

| Machine Dimensions | 1288×1062×1291mm(Without Tri-color Light) |

| Packing Dimensions | 1420×1220×1665mm |

System Setup

If any revision is required, we suggest you contact our engineer to get detailed instruction first. (P.S. All parameters were set up before shipping, usually no adjustment is required.) This section will provide a brief introduction for all parameters, to get detailed adjustment instruction, please contact our technical engineer.

Our service

We are in a good position not only to supply you high quality pnp machine , but also the excellent after sales service.

Well-trained engineers will offer you any technical support.

10 engineers powerful after-sales service team can respond customers queries and enquiries within 8 hours, professional solutions can be offered within 24 hours both workday and holidays.

If you need, please don’t hesitate to send your inquiry.

Provide one-stop SMT assembly production line

Related Products

|

|

|

| Stencil printer FP2636 | Automatic conveyor J12 | Reflow Oven IN6 |

FAQ

Q1: Do you provide software updates?

A: Customers who buy our machine,we can offer free upgrades software for you .

Q2: This is the first time I use this kind of machine, is it easy to operate?

A: We have English user manual and guide video to teach you how to use the machine . If still have question , pls contact us by email / skype / whatapp / phone / trademanager online service.

Q3: Can we customize the machine?

A: Of course. All of our machines can be customized.

Our Company

Hangzhou NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. In this decade, we independently developed NeoDen4, NeoDen IN6, NeoDen K1830, NeoDen FP2636 and other SMT products, which sold well all over the world.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere.

If you need, please don’t hesitate to send your inquiry.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

Bear "Customer first, Excellent first" in mind, we operate closely with our customers and supply them with efficient and expert services for High Quality Robotic Pick And Place - SMD component mounting machine, SMT machine – Neoden , The product will supply to all over the world, such as: USA, Muscat, Macedonia, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.