NeoDen Desktop Pick and Place Machine

NeoDen Desktop Pick and Place Machine

Desktop Pick and Place Machine

2 Heads, ±180° rotation head system

Small volume, low power

High speed and accuracy

Stable performance and easy operation

Description

NeoDen 3V are desktop pick and place machines especially developed for research laboratories and small medium manufacturing enterprises however it will also be suitable for the serious hobbyist.

These automatic pick and place machines are suitable for small batch production, laboratory research and development, product sample trials, LED SMT processing and other similar processes.

Specification

| Product Name | NeoDen Desktop Pick and Place Machine |

||

| Machine Style | Single Gantry with 2 heads | Model | NeoDen 3V-Advanced |

| Placement Rate | 3,500CPH Vision on/5,000CPH Vision off | Placement Accuracy | +/-0.05mm |

| Feeder Capacity | Max Tape Feeder: 44pcs (All 8mm width) | Alignment | Stage Vision |

| Vibration Feeder: 5 | Component Range | Smallest Size: 0402 | |

| Tray Feeder: 10 | Biggest Size: TQFP144 | ||

| Rotation | +/-180° | Max Height: 5mm | |

| Electricity Supply | 110V/220V | Max Board Dimension | 320x390mm |

| Power | 160~200W | Machine Size | L820×W680×H410mm |

| Net Weight | 60Kg | Packing Size | L1010×W790×H580 mm |

Detail

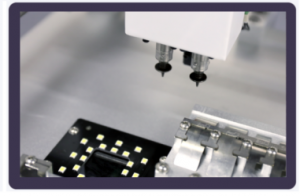

2 heads

Full Vision 2 heads system

±180° rotation satisfy the need of wide range components

Patented Automatic Peel-box

Feeder Capacity: 44*Tape feeder(all 8mm),

5*Vibration feeder, 10* IC Tray feeder

Flexible PCB positioning

Using PCB support bars and pins,

wherever to put the PCB, whatever the shape of PCB.

Integrated Controller

More stable performance and easier to do maintenance.

Quality control

We have QC person stay on the production lines do to the inspection. All products must have been inspected before delivery. we do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

Provide one-stop SMT assembly production line

Click on the picture below to jump to the appropriate product:

About us

About us

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

With global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one stop SMT equipment.

Certification

Exhibition

FAQ

Q1: What’s your MOQ?

A: Most of our products MOQ is 1 set.

Q2: What is your main market?

A: All over the world.

Q3: How far is your factory from the airport and train station?

A: From airport about 2 hours by car, and from train station about 30 minutes. We can pick up you.

If you need, please feel free to contact us for more information!

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.