NeoDen FP2636 Solder Screen Printing

NeoDen FP2636 Solder Screen Printing

Feature

1. Letter mark for each regulating handle,better and easier to operate.

2. Straight damping shaft,ensure the stencil fixed frame can be fastened at random angles, to improve convenience while operating.

3. L supports and pins to fix PCB, applicable for multiple types PCBs’ fixation and printing, more flexible and convenient.

4. Support for single sided as well as double sided PCB.

| Product name | Solder Screen Printing |

| Dimensions | 660×470×245 (mm) |

| Platform height | 190 (mm) |

| Max PCB size | 260×360 (mm) |

| Printing speed | Labor control |

| PCB thickness | 0.5~10 (mm) |

| Repeatability | ±0.01mm |

| Positioning mode | Outside/Reference hole |

| Screen Stencil Size | 260*360mm |

| Fine adjustment range | Z-axis ±15mm X-axis ±15mm Y-axis ±15mm |

| N.W./G.W. | 11/13Kg |

User instructions

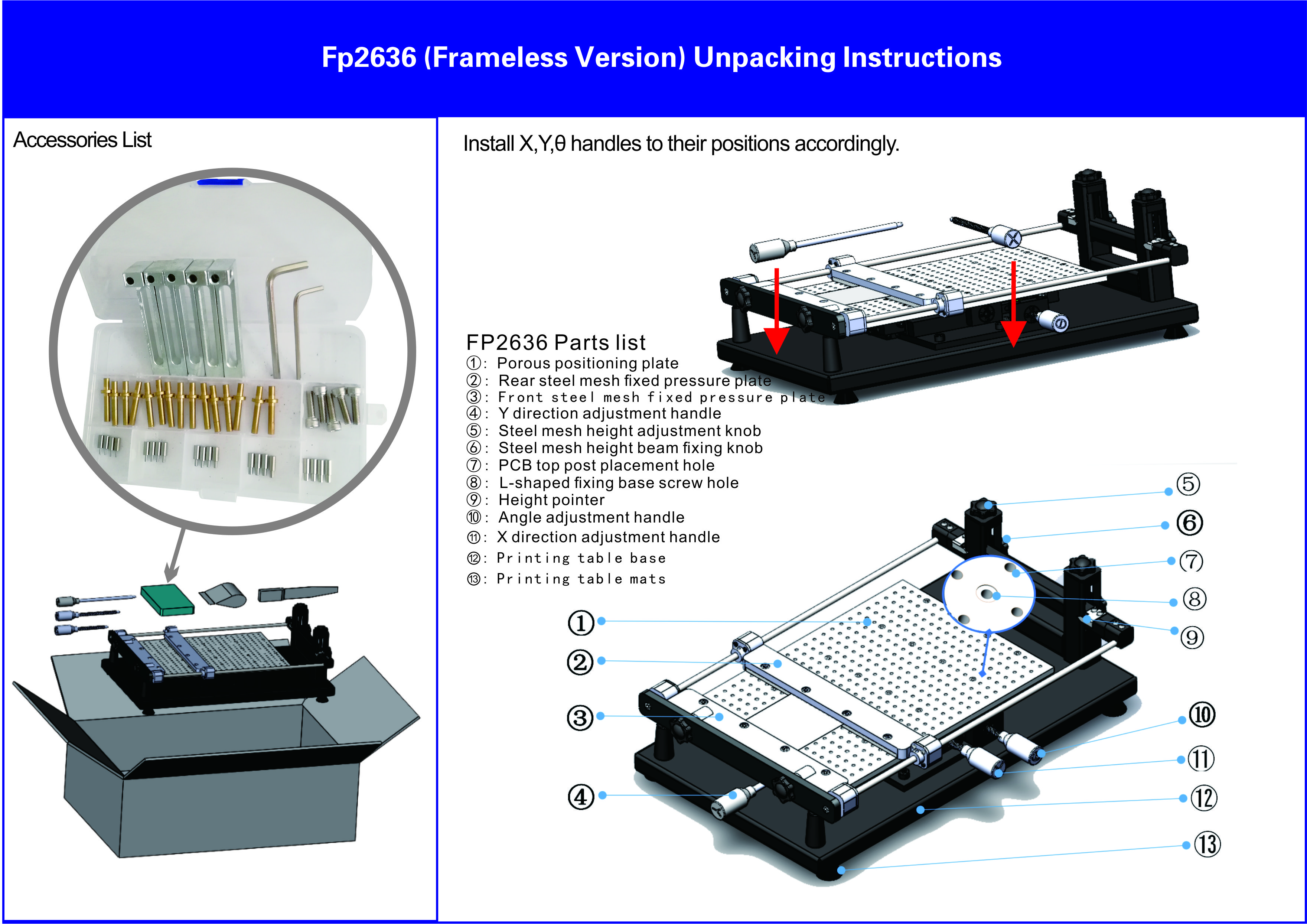

I. Preparation:

FP2636 stencil printer, frameless stencil, PCB, accessory box, solder paste, stirring knife, scraper blade.

II. Install the frameless stencil:

Loosen the four "Set screw", adjust the "rear stencil fixing platen" to a suitable position, loosen the 8 screws on the front and rear stencil fixing platen, and put in the "frameless stencil", tighten the screws.

III. Place the PCB:

Install four "L-shaped seats" and "positioning pins" according to the actual positioning holes on the PCB

(PS: Due to the limited XY adjustment range, the position of the "PCB" should be as close as possible to the hole location of the frameless stencil), if the PCB is easy to deform, you can install the PCB.

IV. Adjust the stencil:

Adjust the "height adjustment handle" to adjust the height of the stencil, adjust the x, y and angle adjustment handle to adjust the X/Y position.

Provide one-stop SMT assembly production line

About us

Factory

Certificate

Exhibition

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate?

A: We have English user manual and guide video to teach you how to use the machine.

If still have question, pls contact us by email / skype / whatapp / phone / trademanager online service.

Q2: How can I buy machine from you?

A: (1) Consult us on line or by e-mail.

(2) Negotiate and confirm the final price, shipping, payment method and other terms.

(3) Send you the perfroma invoice and confirm your order.

(4) Make the payment according to the method put on proforma nvoice.

(5) We prepare your order in terms of the proforma invoice after confirming your full payment. And 100% quality check before shipping

(6) Send your order via express or by air or by sea.

If you need, please feel free to contact us for more information.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.