NeoDen IN12 PCB Reflow Machine

NeoDen IN12 PCB Reflow Machine

Specification

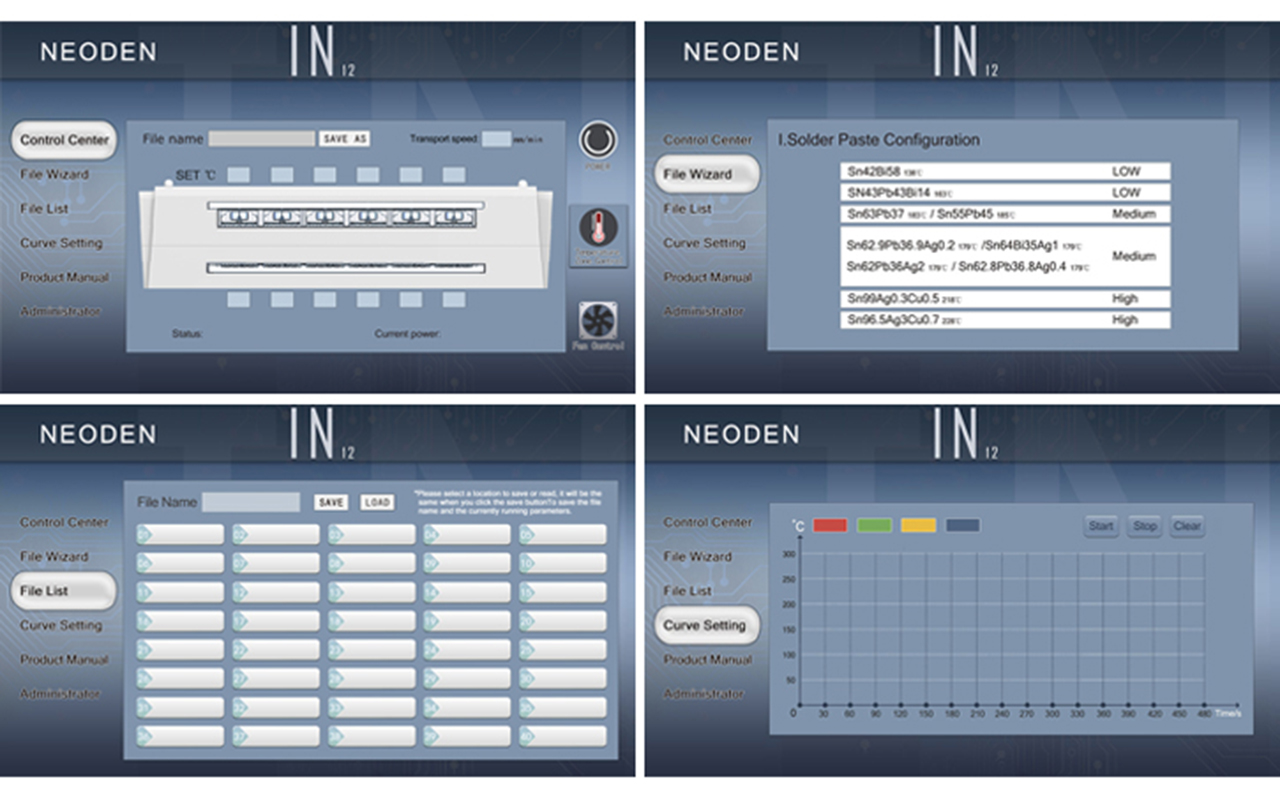

1. The control system has features of high integration, timely response, low failure rate and convenient maintenance.

2. PCB soldering temperature curve can be displayed based on real-time measurement.

3. Lightweight, miniaturization, professional industrial design, flexible application site, more user-friendly.

4. The control system adopts imported chips, and the temperature control accuracy reaches ±0.5%.

Feature

Product name: NeoDen IN12 PCB Reflow Machine

Cooling fan: Upper4

Conveyor speed: 50~600 mm/min

Temperature range: Room temperature~300℃

PCB temperature deviation: ±2℃

Max soldering height(mm): 35mm (includes PCB thickness)

Max soldering width (PCB Width): 350mm

Length process chamber: 1354mm

Electricity supply: AC 220v/single phase

Machine size: L2300mm×W650mm×H1280mm

Heat-up time: 30 min

Net weight: 300Kgs

Details

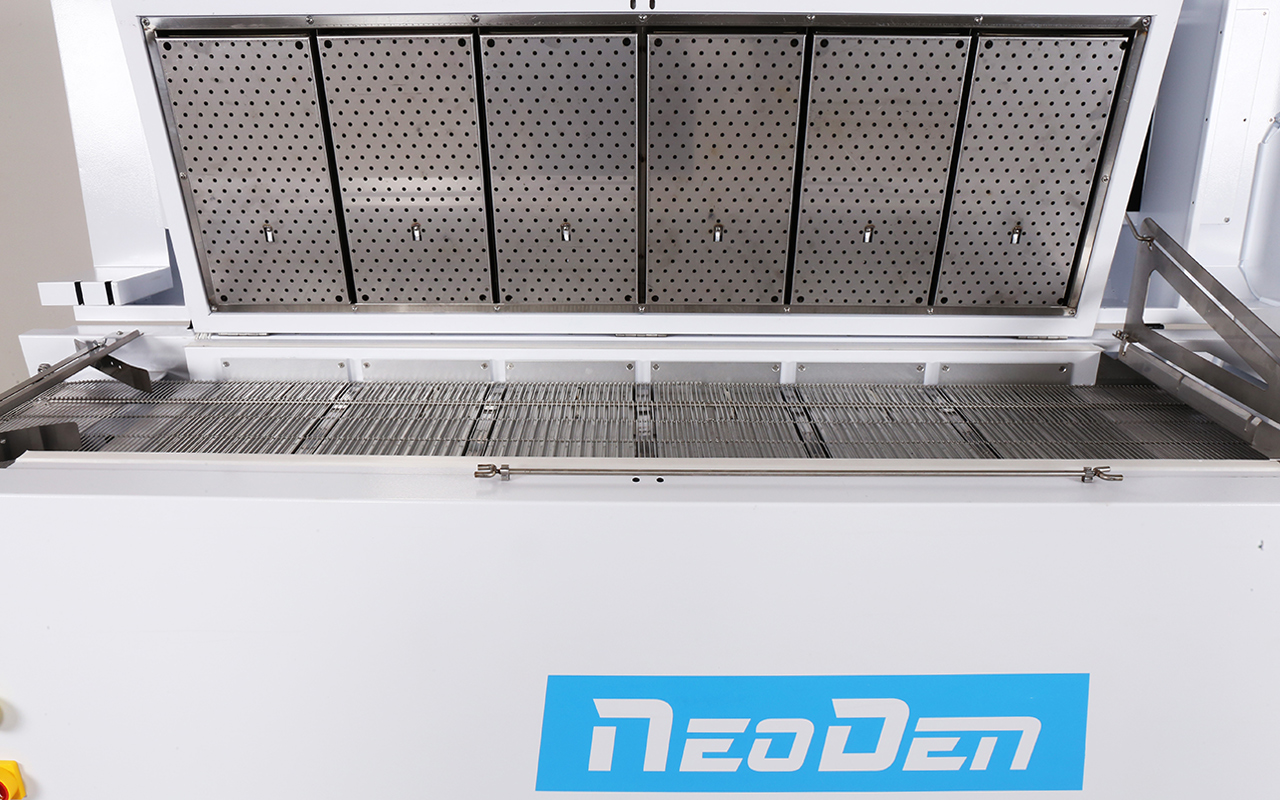

12 temperature zones

High temperature control accuracy

Uniform temperature distribution in the thermal compensation area

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power consumption, low power supply requirements

Operation panel

Hidden screen design

convenient for transportation

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

Power Supply Connection

IN12 power connection is single phase 220V, please connect it against local users actual situation.

Connection as below picture: Open the cover on bottom right corner, L stands for the live wire, N stands for the zero wire, and E stands for the ground wire, connect to the 220V power supply.

According to the wiring requirements, the L should be connected to one live wire, and the N should be connected to one zero wire.

the E should be connected to one ground wire properly.

FAQ

Q1: How do I pay?

A: My friend, there are many ways.

T/T(we prefer this one), Western Union, PayPal, choose your favorite one.

Q2: How about the warranty?

A: We support one year warranty. We will help you in time.

All the spare parts will be provided free of charge for you within the warranty period.

Q3: What is your advantage compared with your competitors?

A: (1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

About us

Factory

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

3 different R&D teams with total 25+ professional R&D engineers,to ensure the better and more advanced developments and new innovation.

NeoDen supplies life-long technical support and service for all of the NeoDen machines, moreover,regular software updates based on the using experiences and actual daily request from the endusers.

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.