NeoDen IN12C Reflow Soldering Station

NeoDen IN12C Reflow Soldering Station

Specification

| Product name | NeoDen IN12C Reflow Soldering Station |

| Model | NeoDen IN12C |

| Heating Zone Quantity | Upper6 / Down6 |

| Cooling Fan | Upper4 |

| Conveyor Speed | 50~600 mm/min |

| Temperature Range | Room temperature~300℃ |

| Temperature Accuracy | 1℃ |

| PCB Temperature Deviation | ±2℃ |

| Max soldering height (mm) | 35mm (includes PCB thickness) |

| Max Soldering Width (PCB Width) | 350mm |

| Length Process Chamber | 1354mm |

| Electricity Supply | AC 220v/single phase |

| Machine Size | L2305mm×W612mm×H1230mm |

| Heat-up Time | 30 min |

| Net Weight | 300Kgs |

Details

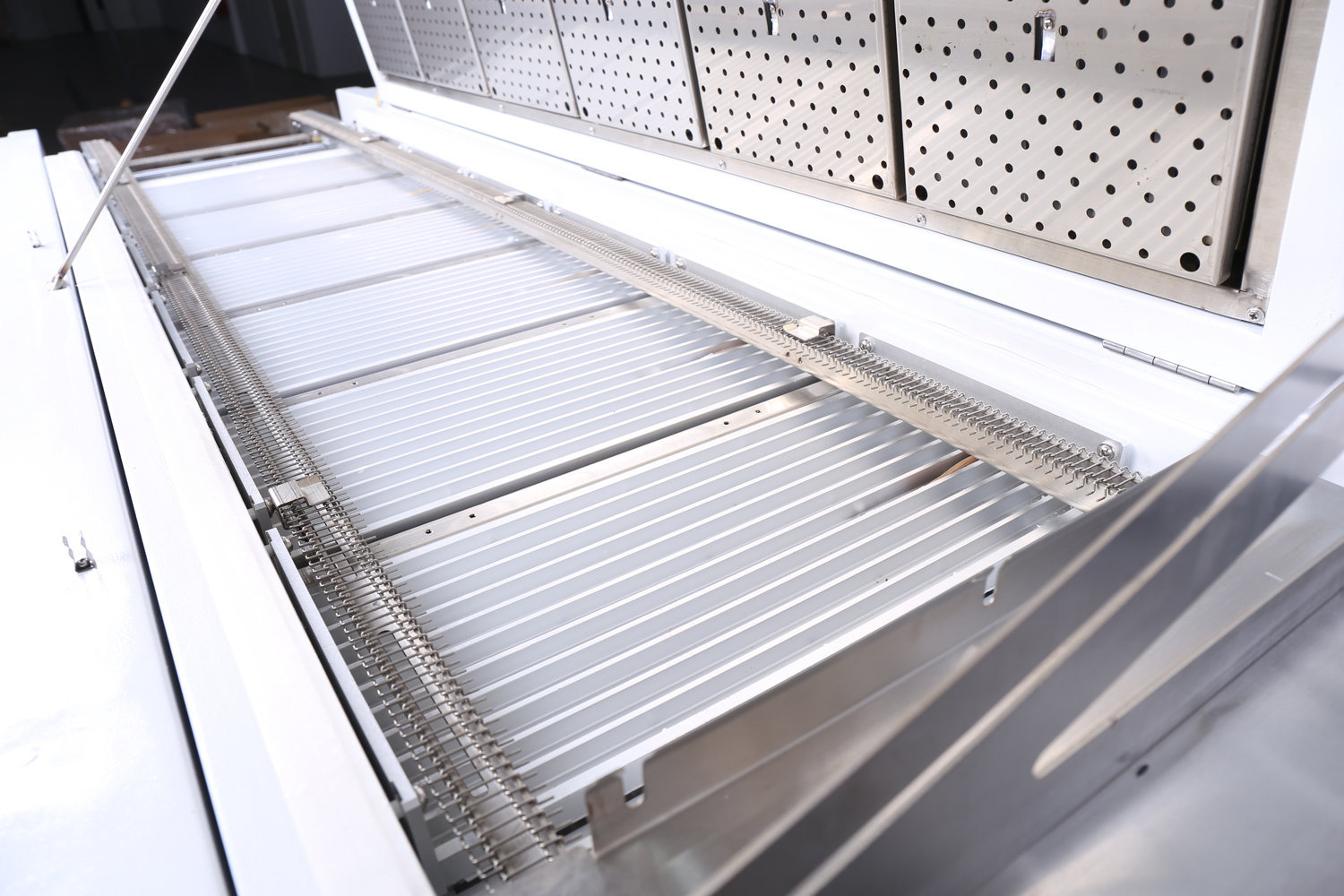

12 Heating Zones

Uniform temperature

High temperature control accuracy

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power and supply requirements

Operation panel

Hidden screen design

Convenient for transportation

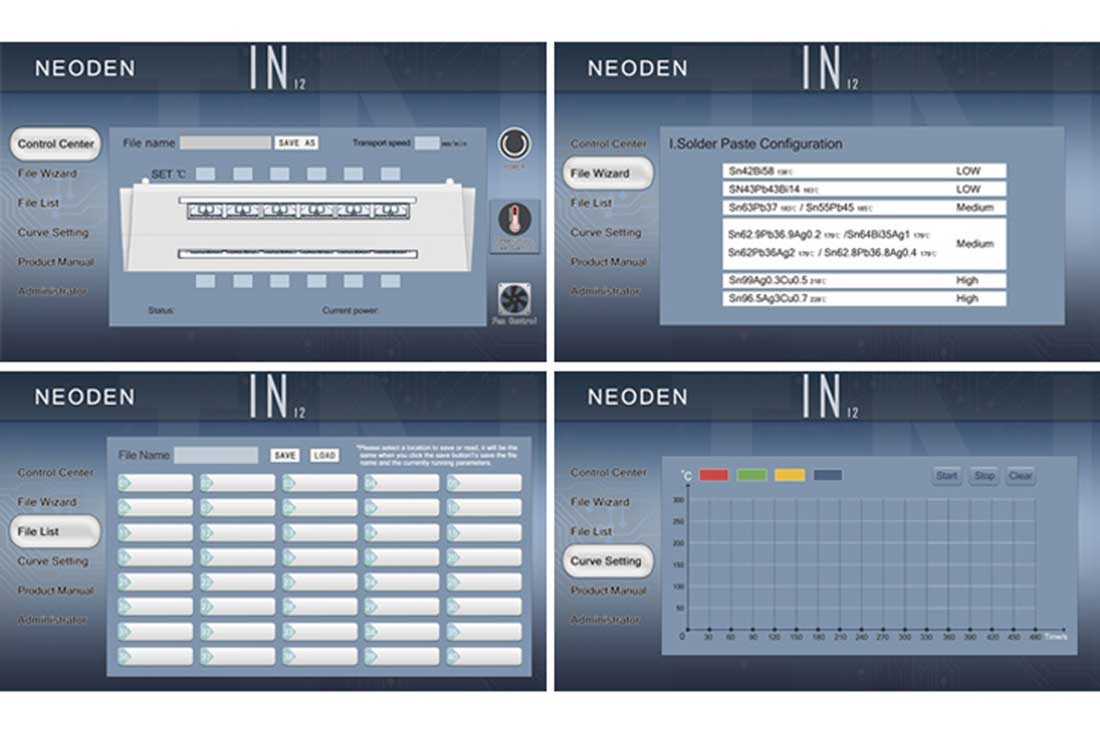

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

Features

1. The control system has the characteristics of high integration, timely response, low failure rate, easy maintenance, etc.

2. Hot air convection, excellent welding performance.

3. Intelligent control, high-sensitivity temperature sensor, effective temperature stabilization.

4. Intelligent, integrated with the PID control algorithm of the custom-developed intelligent control system, easy to use, powerful.

5. professional, unique 4-way board surface temperature monitoring system, so that the actual operation in a timely and comprehensive feedback data, even for complex electronic products can be effective.

6. All temperature zones and cold air zone wind speed adjustable, easily cope with a variety of welding needs.

7. Automatic limit after the top cover is opened, effectively ensure production safety.

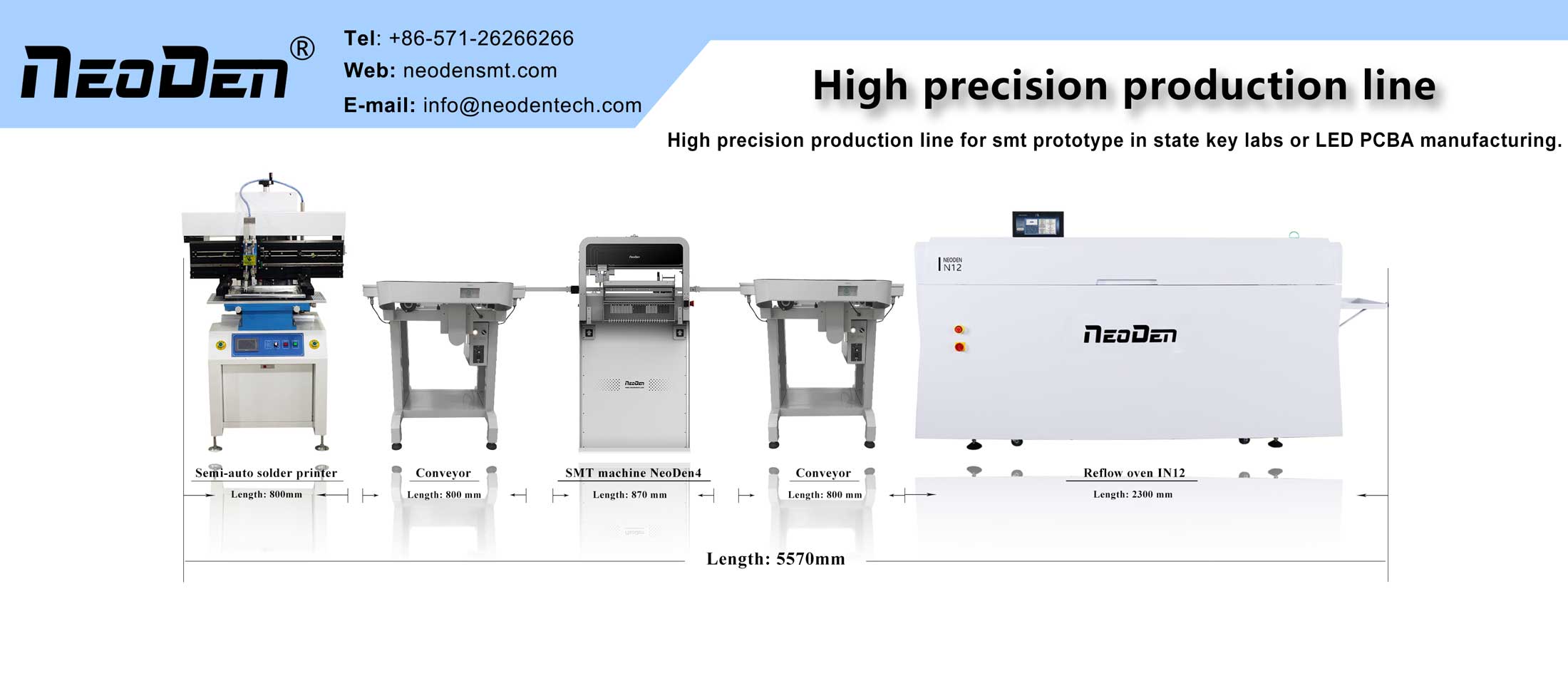

Provide one-stop SMT assembly production line

Related products

FAQ

Q1: What’s is your shipping service?

A: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

Q2: What’s your tem of the delivery?

A: Our ordinary delivery term is FOB Shanghai.

We also accept EXW, CFR, CIF, DDP, DDU etc.

We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

Q3: When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

About us

Factory

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.