NeoDen Pick and Place Low Cost

NeoDen Pick and Place Low Cost

Specification

| Product Name | NeoDen Pick and Place Low Cost |

||

| Machine Style | Single Gantry with 2 heads | Model | NeoDen 3V-Advanced |

| Placement Rate | 3,500CPH Vision on/5,000CPH Vision off | Placement Accuracy | +/-0.05mm |

| Feeder Capacity | Max Tape Feeder: 44pcs (All 8mm width) | Alignment | Stage Vision |

| Vibration Feeder: 5 | Component Range | Smallest Size: 0402 | |

| Tray Feeder: 10 | Biggest Size: TQFP144 | ||

| Rotation | +/-180° | Max Height: 5mm | |

| Electricity Supply | 110V/220V | Max Board Dimension | 320x390mm |

| Power | 160~200W | Machine Size | L820×W680×H410mm |

| Net Weight | 60Kg | Packing Size | L1010×W790×H580 mm |

Detail

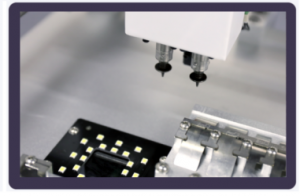

2 heads

Full Vision 2 heads system

±180° rotation satisfy the need of wide range components

Patented Automatic Peel-box

Feeder Capacity: 44*Tape feeder(all 8mm),

5*Vibration feeder, 10* IC Tray feeder

Flexible PCB positioning

Using PCB support bars and pins,

wherever to put the PCB, whatever the shape of PCB.

Integrated Controller

More stable performance and easier to do maintenance.

|

1) Pick and place machine NeoDen 3V-A: 1

|

2) PCB support bar: 4units |

| 3) PCB support pin: 8units | 4) Electromagnet: 1pack |

| 5) Needle: 2sets | 6) Allen wren set: 1 |

| 7) Tool box: 1unit | 8) Cleaning needle: 3units |

| 9) Power cord: 1unit | 10) Double side adhesive tape: 1set |

| 11) Silicon tube: 0.5m | 12) Fuse(1A): 2units |

| 13) 8G flash drive: 1unit | 14) Reel holder stand:1set |

| 15) Nozzle rubber 0.3mm: 5units | 16) Nozzle rubber 1.0mm: 5units |

| 17) Vibration feeder: 1unit | |

Click on the picture below to jump to the appropriate product:

PCB Angle Correction

PCB angle will influence the accuracy of mounting. The angle more closer to 0 degree the better, and the angel deviation need to be within 1 degree.

The angle of PCB is generated according to panelized PCB coordinates, but we can also adjust the angle by manual.

Click” PCB angle” button, according to the index of machine to choose two points, then a new PCB angle will be generated. ( Note, the two points need to be in one vertical or horizontal line)

Under panelized PCB mode, “ PCB angle” is locked. You need to correct from panelized PCB to single PCB( 1*1), after confirm the PCB angle, you can change back to panelized PCB model.

About us

About us

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

③ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

FAQ

Q1: What we can do for you?

A: Total SMT Machines and Solution, professional Technical Support and Service.

Q2: Can we customize the machine?

A: Of course. All of our machines can be customized.

Q3: How can I place an order?

A: You can contact any of our sales person for an order.

Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.

If you need, please feel free to contact us for more information!

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.