NeoDen Pick and Place

NeoDen Pick and Place video

NeoDen Pick and Place

Description

Product name: NeoDen Pick and Place

Model: NeoDen 10

IC Tray Capacity: 20

Smallest Component size: 0201 (electronic feeder)

Applicable Components: 0201, Fine-pitch IC, Led Component, Diode, Triode

Component Height Maximum: 16mm

Applicable PCB size: 500mm*300mm (1500 optinal)

Power Supply: 220V, 50Hz (convertible to 110V)

Air source: 0.6MPa

N.W.: 1100Kgs

Product Detail

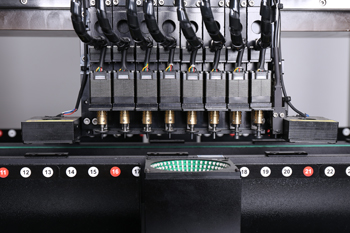

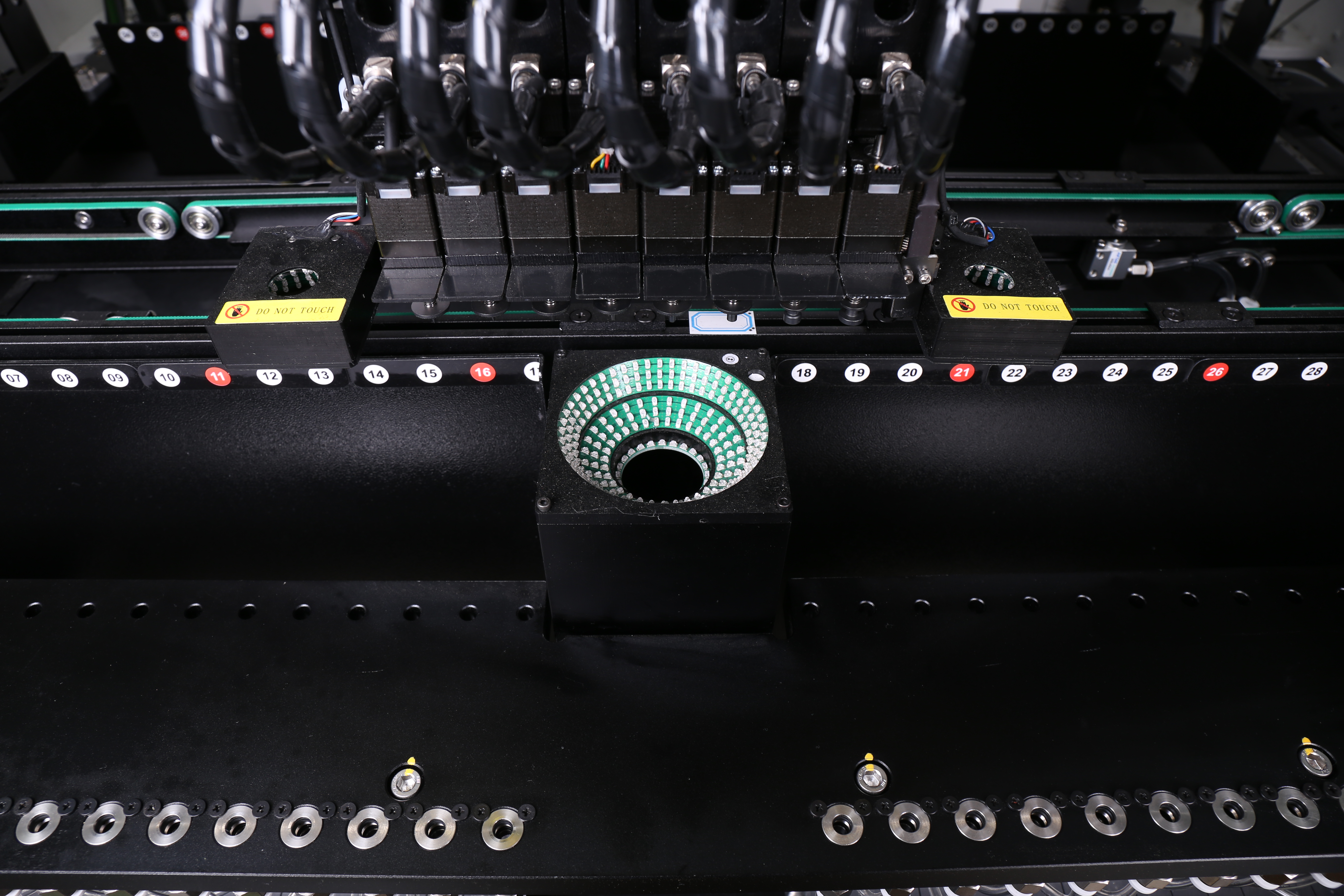

8 heads with Vision enabled

Rotation: +/-180 (360)

High speed repeatable placement accuracy

66 Reel tape feeders

Be calibrated automatically and promptly

Ensure easy operation and high efficiency

Double mark cameras

Better calibration

Improves the overall speed of the machine

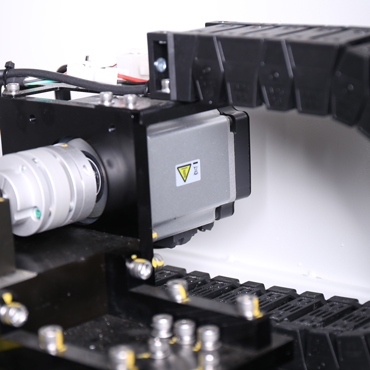

Drive Motor

Panasonic Servo Motor A6

Make the machine to function more accurate

High-definition display

Display size: 12 inch

Makes the machine more convenient to use

Warning light

Triple color of light

Beautiful and elegant indicator design

Description

8 independent heads with fully closed-loop control system support all 8mm feeder pick up simultaneously, speed up to 13,000 CPH.

Patented sensor, besides common PCB, can also mount black PCB with high accuracy.

The magnetic linear encoder system real-time monitor the machine's accuracy and enables machine to correct error parameter automatically.

Support 1.5M LED light bar placement (optional configuration).

Packaging & Shipping

Packaging:

one piece in one wooden case

Suitable quantity to an export wooden case

other packing accessories in regular

Customer required packing is available

Shipping:

by air, sea, or express

Delivery time:

about 15~30 days after order details and production confirmed.

Comparison of similar products

If you need, please feel free to contact us for more information.

FAQ

Q1: How many workers in your factory?

A: More than 200 workers.

Q2: How far is your factory from the airport and train station?

A: from airport about 2 hours by car, and from train station about 30 minutes.

We can pick up you.

Q3: Can I request to change the form of packaging and transportation?

A: Yes, we can change the form of the packaging and transportation according to your request.

But you have to bear their own costs incurred during this period and the spreads.

About us

Factory

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

Owned the own machining center, skilled assembler,tester and QC engineers, to ensure the strong abilities for NeoDen machines manufacturing, quality and delivery.

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

Skilled and professional english support&service engineers, to ensure the prompt response within 8 hours, solution provides within 24 hours.

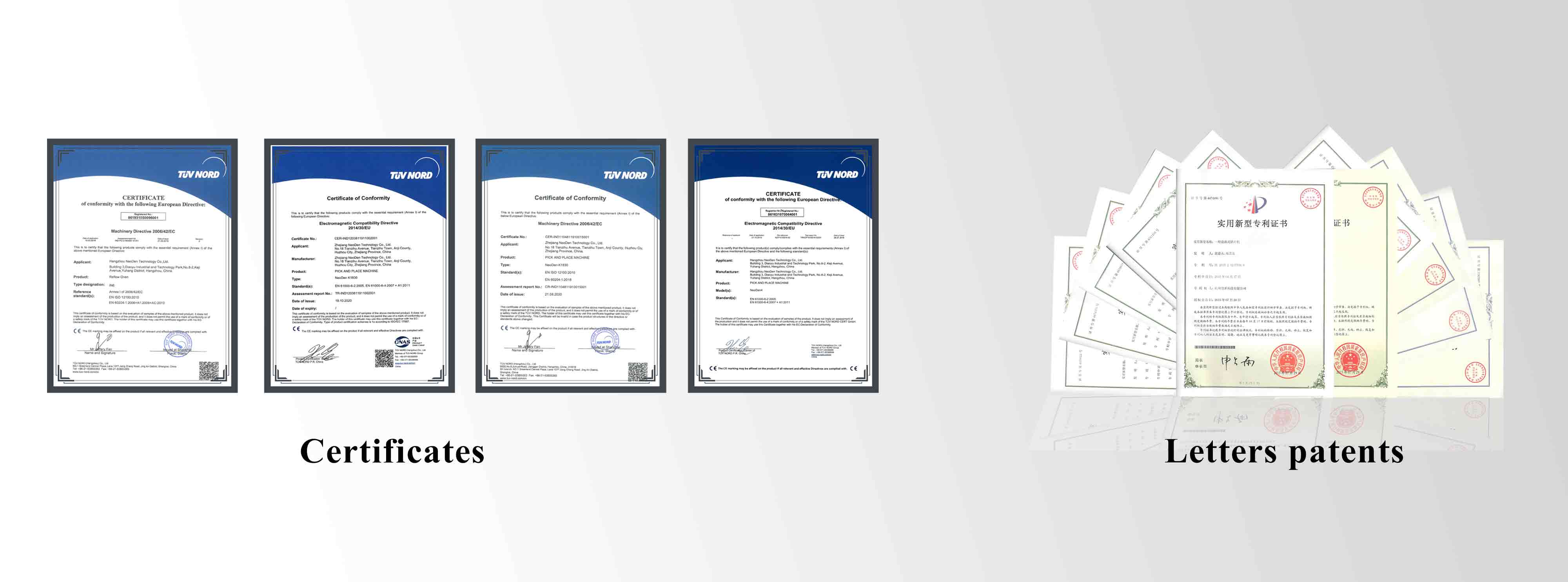

Certification

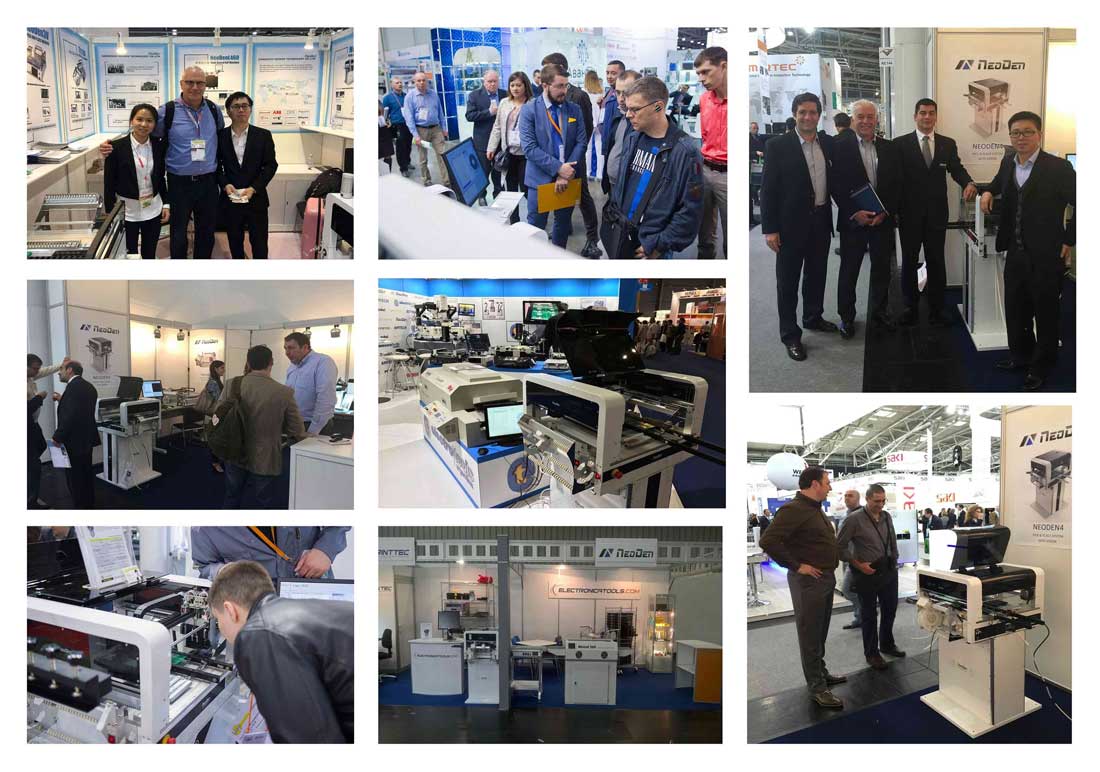

Exhibition

If you need, please feel free to contact us for more information.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.