NeoDen4 LED SMT PCB pick and place machine

NeoDen4 LED SMT PCB pick and place machine Video

NeoDen4 LED SMT PCB pick and place machine

Design principles

Specifications

Product name: NeoDen4 LED SMT PCB pick and place machine

Model: NeoDen4

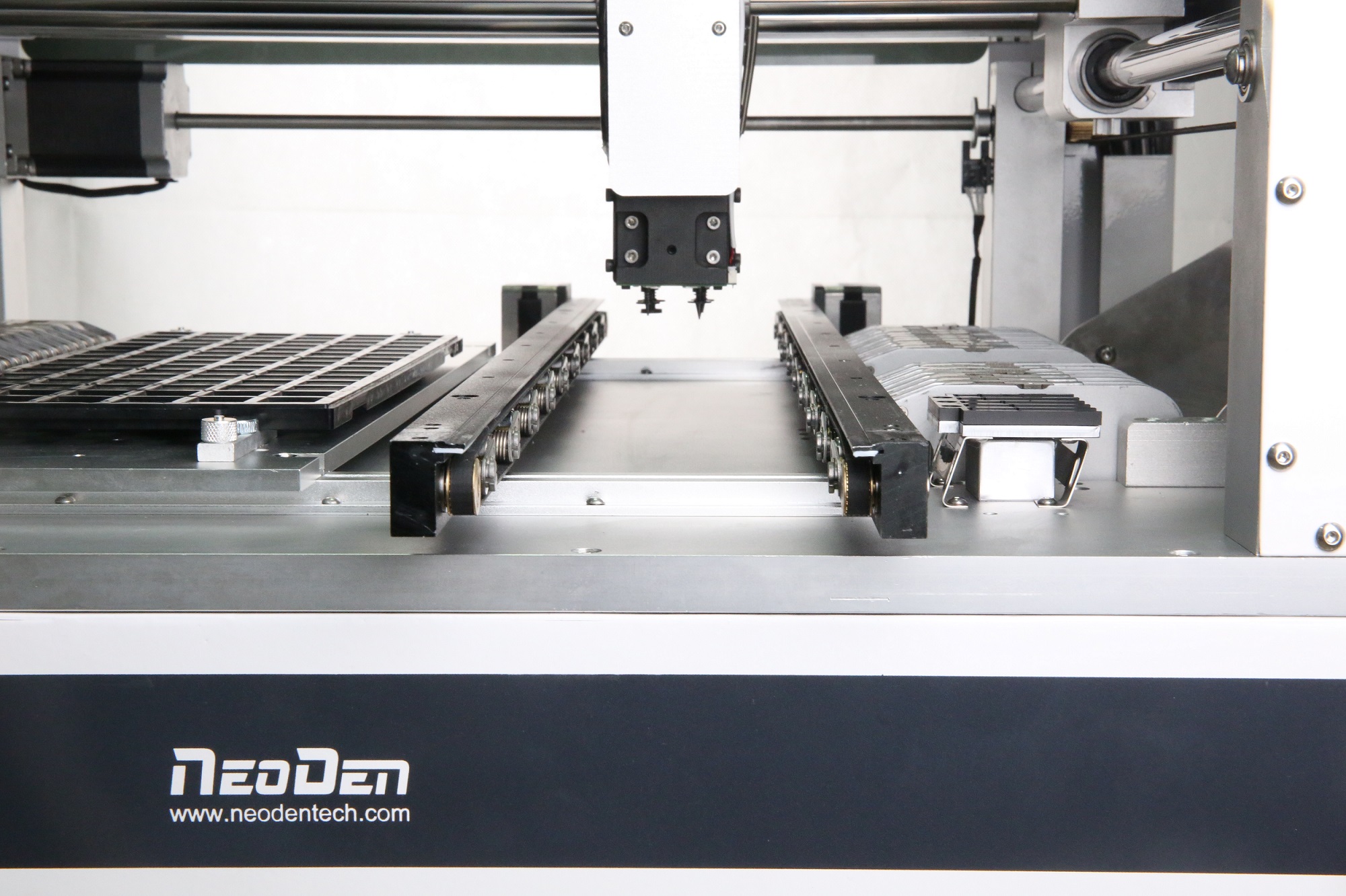

Machine Style: Single gantry with 4 heads

Placement Rate: 4000 CPH

External Dimension: L 870×W 680×H 480mm

Max applicable PCB: 290mm*1200mm

Feeders: 48pcs

Average working power: 220V/160W

Component Range: Smallest Size: 0201, Biggest Size: TQFP240, Max Height: 5mm

Details

On-line dual rails

Vision system

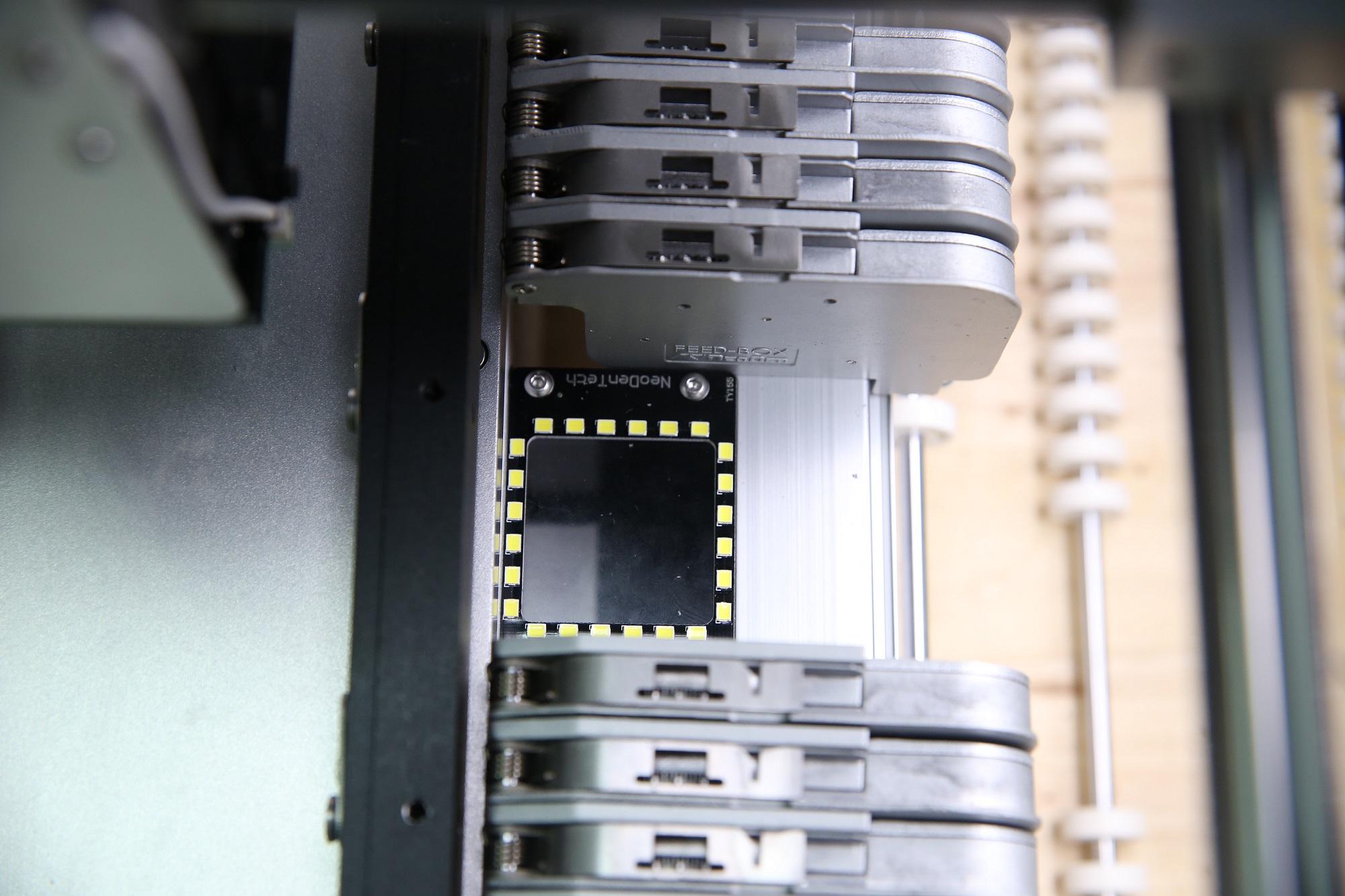

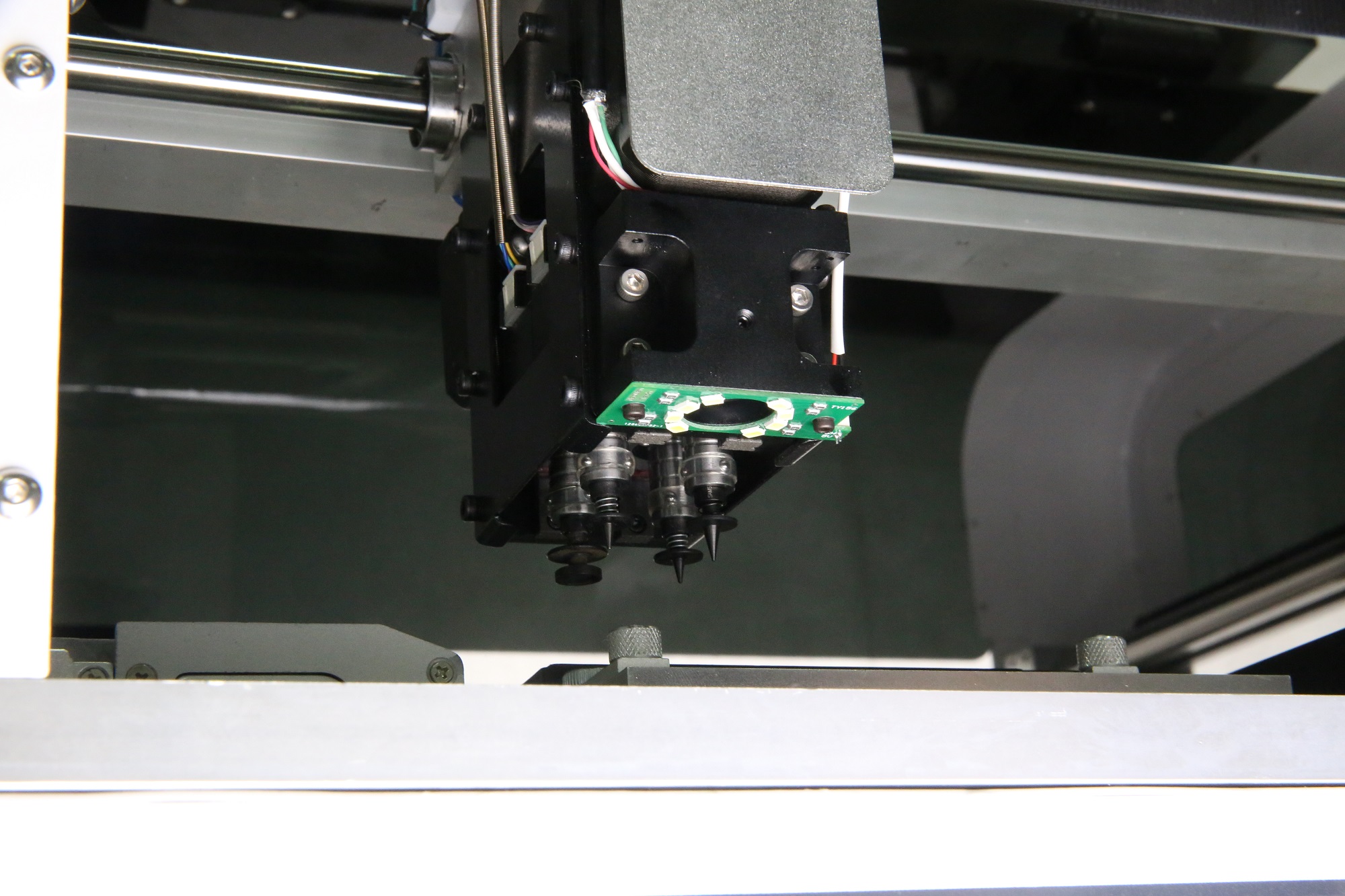

The NeoDen4 features a high-precision, two-camera vision system.

Vision System - Upwards and Downwards Cameras

Four high precision nozzles

Gantry with four nozzles (±180° rotation)

Electric tape-and-reel feeders

Packing

Quality Control

We have QC person stay on the production lines do to the inspection.

All products must have been inspected before delivery.we do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

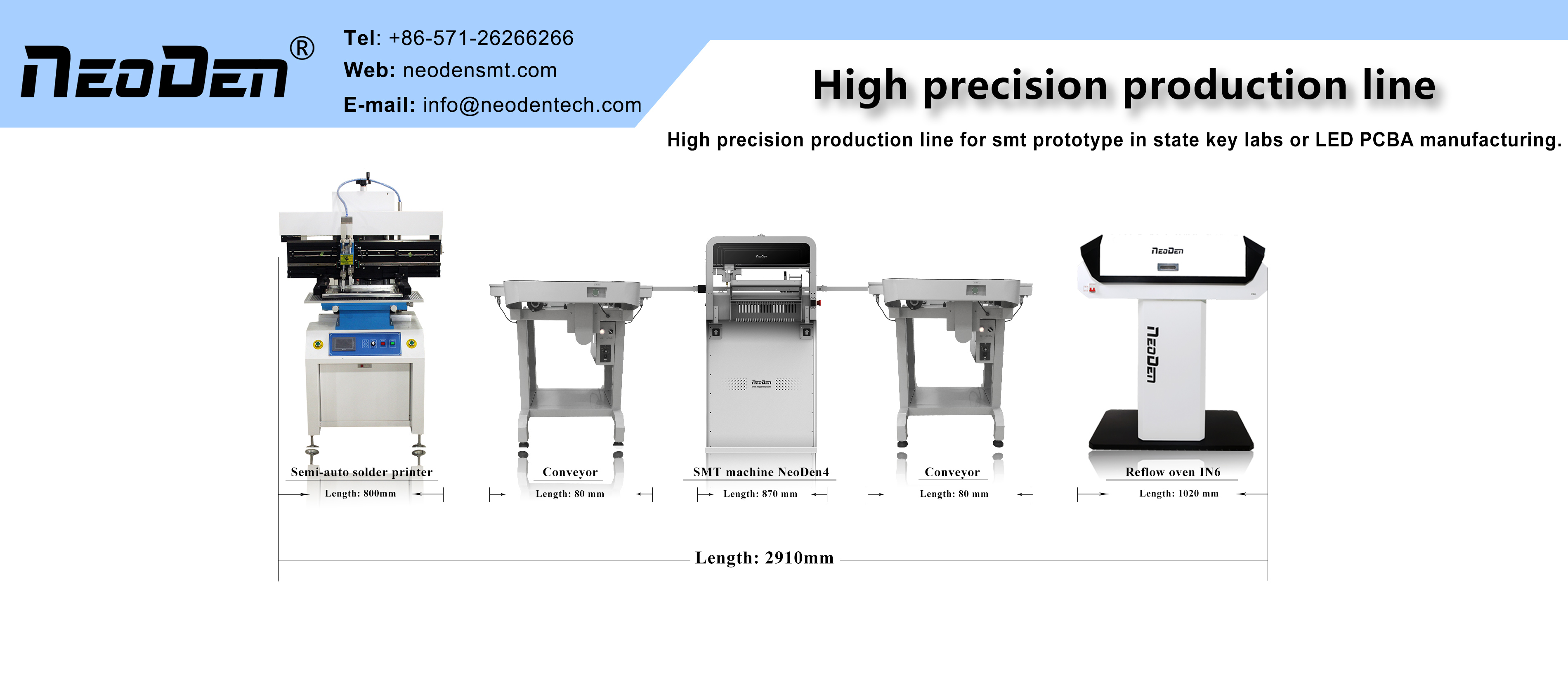

Provide one-stop SMT assembly production line

Related products

If you need, please feel free to contact us.

FAQ

Q1: Do you have a export licence?

A: Yes.

Q2: Do you have after-sale service?

A: Yes, Good after-sale service, handling the customer complaint and solve problem for customers.

Q3: Can l visit your factory?

A:By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.

Q4: Have your products been exported?

A: Yes, they have been exported to USA, Canada, Australia, Russia, Chile, Panama, Nicaragua, UAE, Saudi Arabia, Egypt, Sri Lanka, Nigeria, Iran, Vietnam, Indonisia, Singapore, Greece, Netherland, Georgia, Romania, Ireland, India, Thailand, Pakistan, Philippines, Singapore, HK, Taiwan...

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We have our own R & D team and own factory, taking advantage of our own rich experienced R&D, well trained production, won great reputation from the world wide customers.

With global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one stop SMT equipment.

Exhibition

Certificates

If you need, please feel free to contact us.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.