Power semiconductor driver circuit is an important subcategory of integrated circuits, powerful, used for IGBT driver ICs in addition to providing drive level and current, often with drive protection functions, including desaturation short circuit protection, undervoltage shutdown, Miller clamp, two-stage shutdown, soft shutdown, SRC (slew rate control), etc. The products also have different levels of insulation performance. However, as an integrated circuit, its package determines the maximum power consumption, the driver IC output current can be more than 10A in some cases, but still can not meet the driving needs of high current IGBT modules, this paper will discuss the IGBT driving current and current expansion.

How to expand the driver current

When the drive current needs to be increased, or when driving IGBTs with high current and large gate capacitance, it is necessary to expand the current for the driver IC.

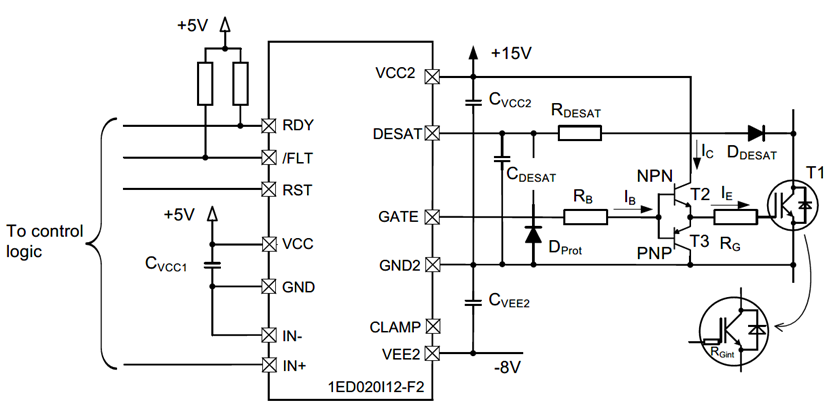

Using bipolar transistors

The most typical design of IGBT gate driver is to realize current expansion by using complementary emitter follower. The output current of emitter follower transistor is determined by the DC gain of transistor hFE or β and the base current IB, when the current needed to drive IGBT is larger than IB*β, then the transistor will enter the linear working area and the output drive current is insufficient, then the charging and discharging speed of IGBT capacitor will become slower and the IGBT losses increase.

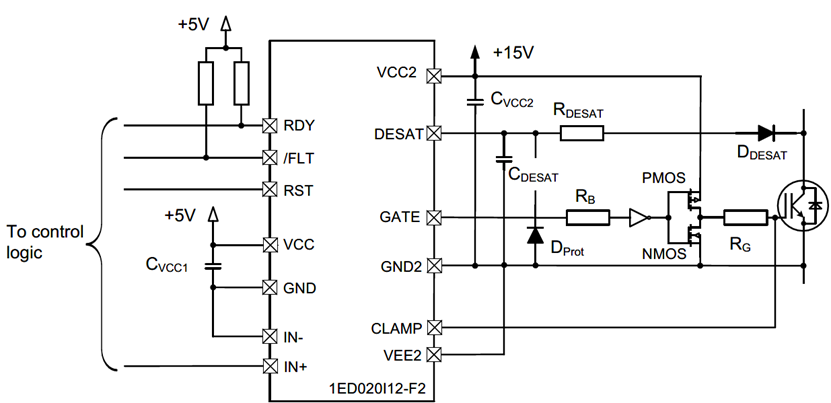

Using MOSFETs

MOSFETs can also be used for current expansion of the driver, the circuit is generally composed of PMOS + NMOS, but the logic level of the circuit structure is the opposite of the transistor push-pull. The design of the upper tube PMOS source is connected to the positive power supply, the gate is lower than the source of a given voltage PMOS on, and the driver IC output is generally high level turn on, so the use of PMOS + NMOS structure may require an inverter in the design.

With bipolar transistors or MOSFETs?

(1) Efficiency differences, usually in high-power applications, the switching frequency is not very high, so the conduction loss is the main, when the transistor has the advantage. Many current high power density designs, such as electric vehicle motor drives, where heat dissipation is difficult and temperatures are high within the enclosed case, when efficiency is very important and transistor circuits can be chosen.

(2) The output of the bipolar transistor solution has a voltage drop caused by VCE(sat), the supply voltage needs to be increased to compensate for the drive tube VCE(sat) to achieve a drive voltage of 15V, while the MOSFET solution can almost achieve a rail-to-rail output.

(3) MOSFET withstand voltage, VGS only about 20V, which may be a problem that needs attention when using positive and negative power supplies.

(4) MOSFETs have a negative temperature coefficient of Rds(on), while bipolar transistors have a positive temperature coefficient, and MOSFETs have a thermal runaway problem when connected in parallel.

(5) If driving Si/SiC MOSFETs, the switching speed of bipolar transistors is usually slower than the driving object MOSFETs, which should be considered to use MOSFETs to extend the current.

(6) The robustness of the input stage to ESD and surge voltage, bipolar transistor PN junction has a significant advantage compared to MOS gate oxide.

Bipolar transistors and MOSFET characteristics are not the same, what to use or you need to decide for yourself in accordance with the system design requirements.

Quick facts about NeoDen

① Established in 2010, 200+ employees, 8000+ Sq.m. factory.

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040.

③ Successful 10000+ customers across the globe.

④ 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa.

⑤ R&D Center: 3 R&D departments with 25+ professional R&D engineers.

⑥ Listed with CE and got 50+ patents.

⑦ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours.

Post time: May-17-2022