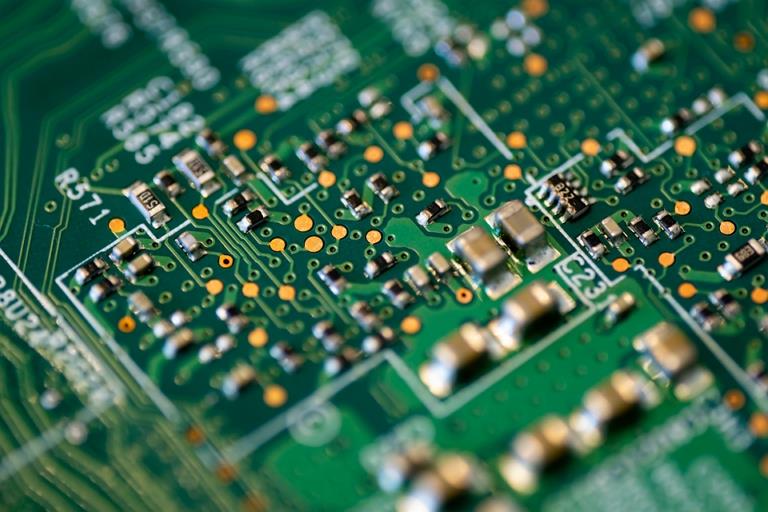

As we all know, the progress of making a PCB is very complicated, a lot of professional equipments are required.

The general process is:

Print circuit board→inner circuit→pressing→drilling→plated through-hole (primary copper)→ outer circuit (secondary copper)→solder→resistant green paint→text printing→ processing→forming cutting→final inspection and packing.

And then you could use the blanket boards to make your own design!

A production line of printed circuit boards generally requires:

- film laminator,

- exposure machine,

- etching machine,

- AOI machine,

- punching machine,

- plate fusion machine,

- laminator,

- target machine,

- edge milling machine,

- drilling machine,

- sinking copper wire,

- Electroplating line,

- green oil mill plate line,

- front and back processing line,

- screen printing machine,

- surface mounting equipment --SMT machines,

- trimming machine,

- electric measuring machine,

- warping machine.

These machines above are major equipment, and there are also many auxiliary equipments needed to produce a PCB.

Article and picture from the internet, if any infringement pls firstly contact us to delete.

NeoDen provides a full SMT assembly line solutions, including SMT reflow oven, wave soldering machine, pick and place machine, solder paste printer, PCB loader, PCB unloader, chip mounter, SMT AOI machine, SMT SPI machine, SMT X-Ray machine, SMT assembly line equipment, PCB production Equipment SMT spare parts, etc any kind SMT machines you may need, please contact us for more information:

Hangzhou NeoDen Technology Co., Ltd

Web: www.neodentech.com

Email: info@neodentech.com

Post time: Mar-14-2020