PCB assembly Defect Coverage Using Automated Optical Inspection (AOI)

PCB assembly Defect Coverage Using Automated Optical Inspection (AOI)

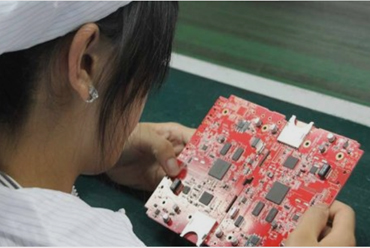

Automated Optical Inspection (AOI), which is an automated visual inspection of a Printed Circuit Board (PCB), provides 100% visible component and solder-joint inspection. This testing method has been in use in PCB manufacturing for almost two decades. It plays a critical role in ensuring that there are no random faults in the assembly. The technique, which uses lighting, cameras, and vision computers, is incorporated in the assembly process to guarantee the highest possible quality throughout each phase of a product’s life cycle. The method enables fast and accurate inspection and can be applied at various stages of the manufacturing process. So, what all things can an Automated Optical Inspection (AOI) equipment checks in an PCB assembly?

Defect Detection Using AOI

The sooner the faults are detected, the easier it will be to make the final production to match design requirements without any flaws. This well-known, accepted technology can be used to check the following in a PCB assembly:

- Nodules, scratches and stains

- Open circuits, shorts and thinning of the solder

- Incorrect, missing and skewed components

- Insufficient paste area, smearing, and bridging

- Missing or offset chips, skewed chips and chip-orientation defects

- Solder bridges, and lifted leads

- Line width violations

- Spacing violation

- Excess copper, and missing pad

- Trace shorts, cuts, jumps

- Area defects

- Component offsets, component polarity,

- Component presence or absence, component skew from surface mount pads

- Excessive solder joints and insufficient solder joints

- Flipped components

- Paste around leads, solder bridges, and solder paste registration

With these errors being detected at the earliest stage, manufacturers can produce the board to the required standards. To contribute to the testing processes, there are several equipment available with advanced lighting, optics, and image processing capabilities for exceptional defect coverage. These machines offer simple, intelligent and powerful performance, leading to reduce your rework costs and improve the testing process. AOI being a critical testing method that determines the overall quality of the board, it is important to avail the service from leading companies. It is always an ideal choice to partner with PCB manufacturers who offer AOI testing hand-in-hand. This helps the manufacturer to test the board at every stage of the assembly without any delay.

Post time: Jun-15-2020