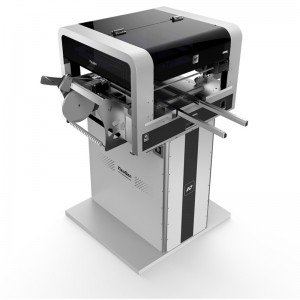

Place Machine – PCB assembly machine NeoDen4 – Neoden

Place Machine – PCB assembly machine NeoDen4 – Neoden Detail:

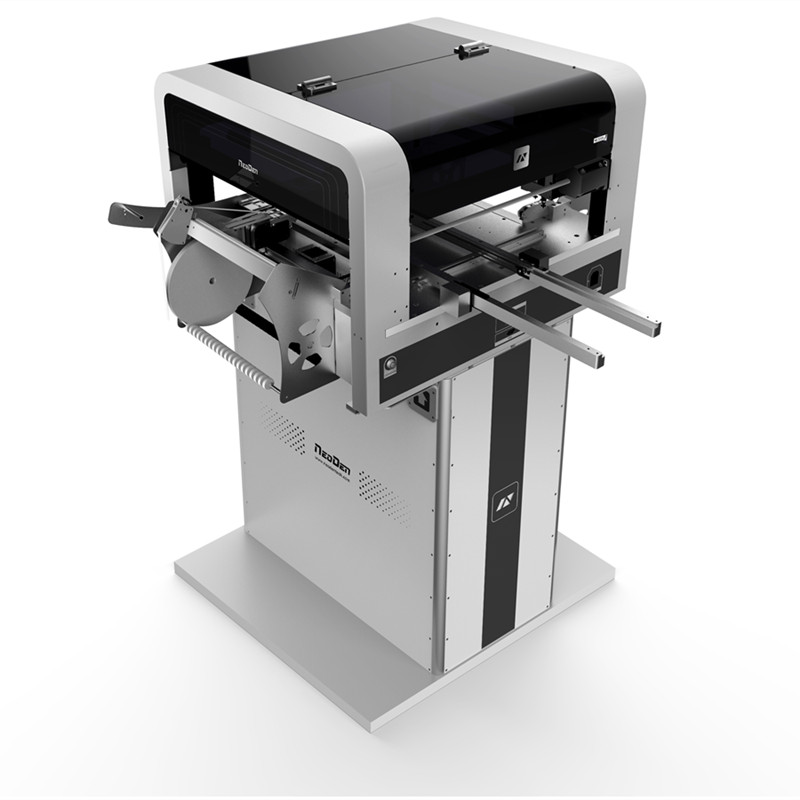

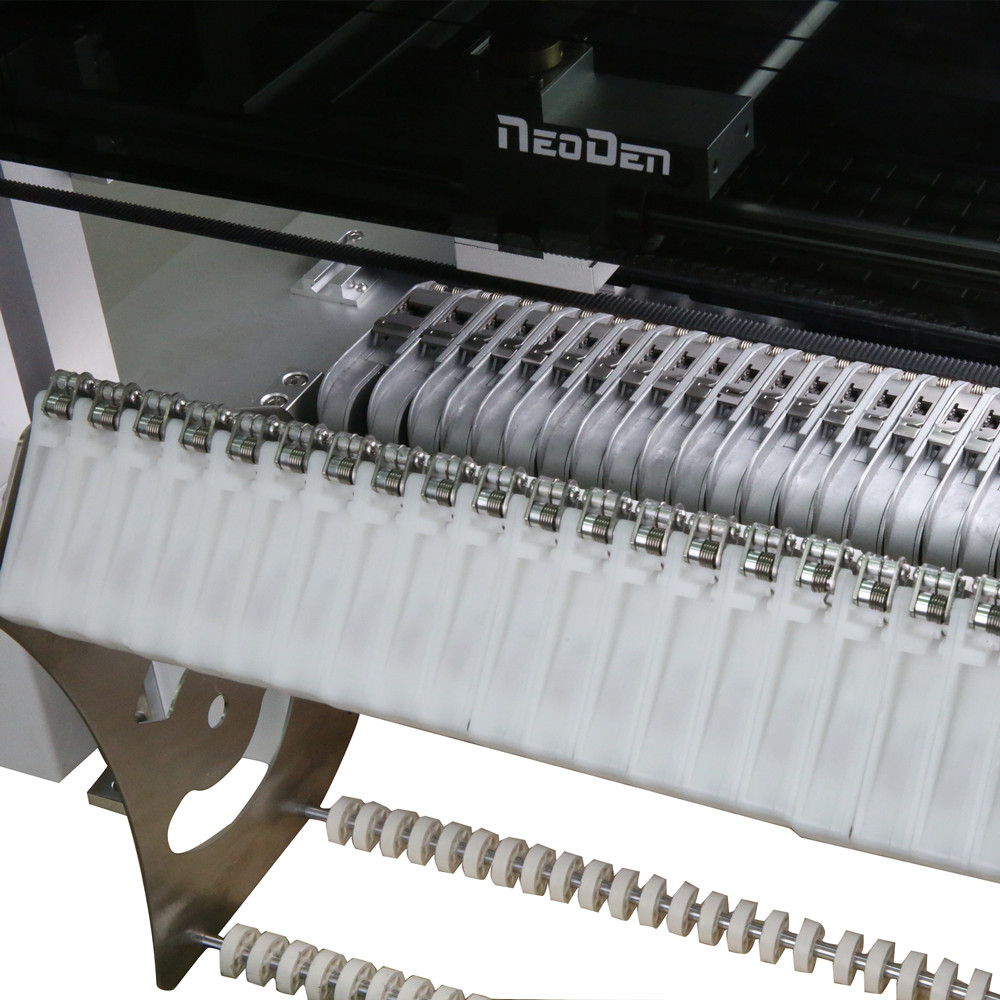

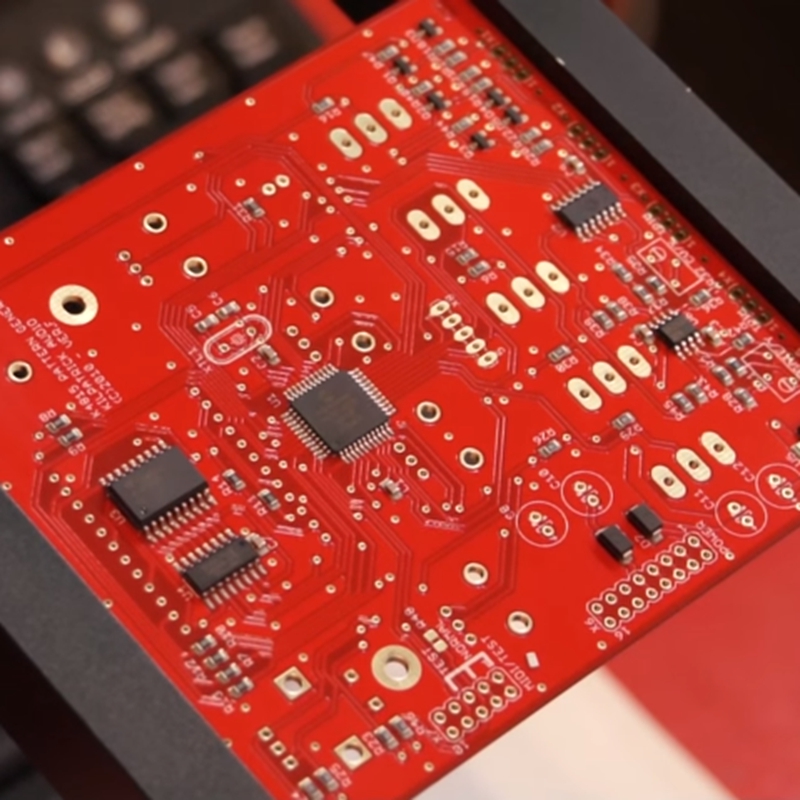

NeoDen4 is a flexible pick and place machine for all types of production.

With placement rates of 10,000 cph, up to 48 feeder slots, auto rails and electronic feeders, users can move from prototype into production on the same machine, saving programming and job setup time.

It is a compact placing machine that offers the flexibility (component flexibility, PCB flexibility and production flexibility) and speed to meet the demands of an ever-changing market.

Spotlights

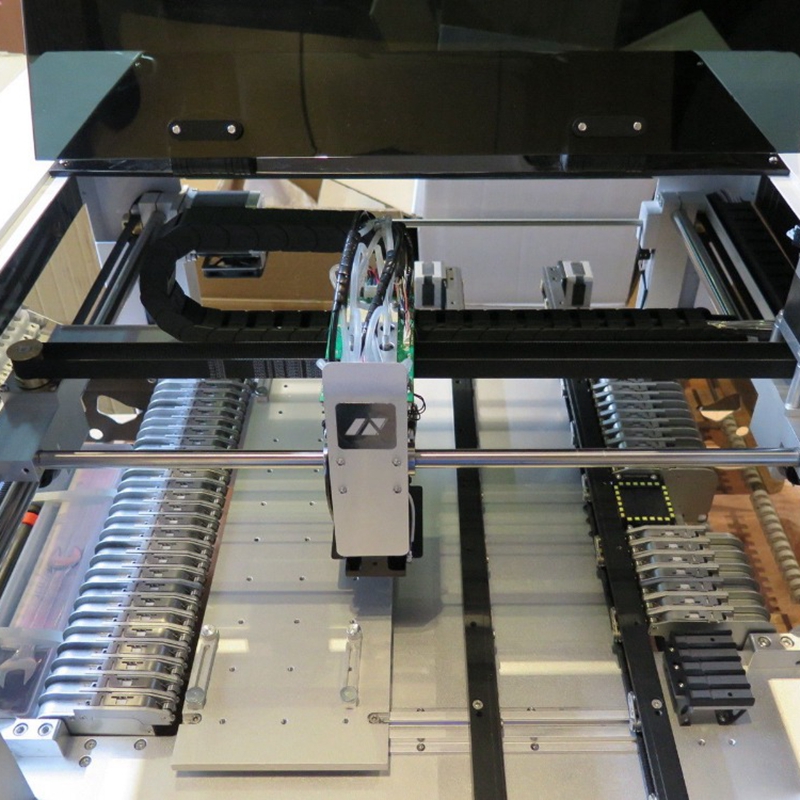

- Vision system

An up-looking camera and a down-looking camera identifies and calibrates the different components simultaneously, and tremendously improves the accuracy of placement from 0201 to BGA

- Four precision heads

4 high-precision placement heads with ±180° rotation that adopts suspended, fully symmetric and high degree of coupling way, to ensure it can mount components with higher space, more gentle and more accurate

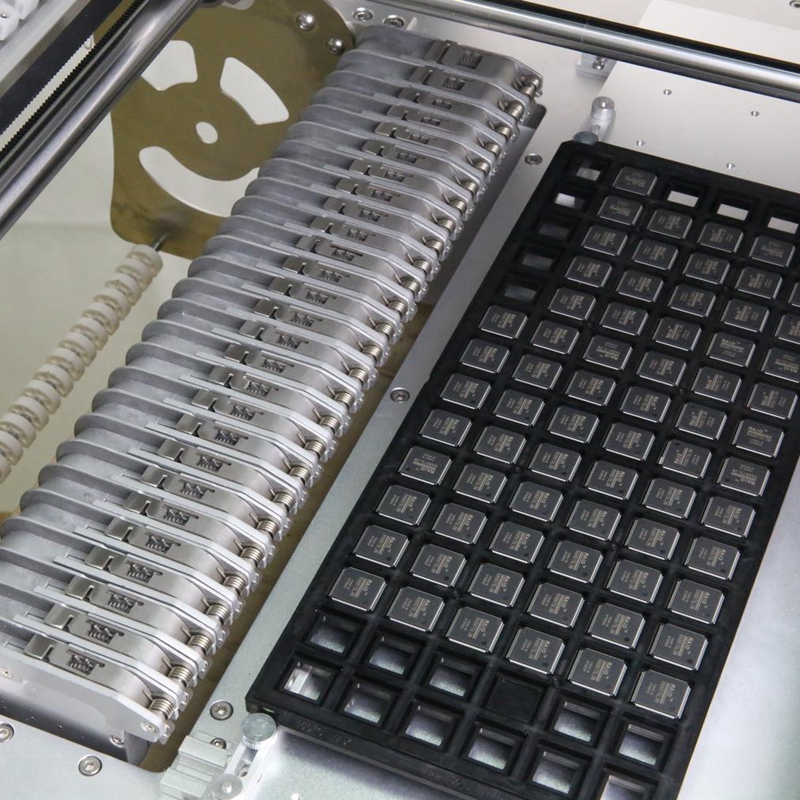

- Auto Electronic Feeders

Adopts feeding error corrections technique to help smooth the picking and reduce the deviation

- General conveyor is supported

With a conveyor port, One-Stop SMT production line can be setup, which is more time-saving and labor-saving

- Industrial PC motherboard

32G solid state drives, read/write faster and more stable, with power-off protection function

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

Bear "Customer first, Excellent first" in mind, we operate closely with our customers and supply them with efficient and expert services for Place Machine – PCB assembly machine NeoDen4 – Neoden , The product will supply to all over the world, such as: Montreal, Afghanistan, Canada, The credibility is the priority, and the service is the vitality. We promise we have now the ability to offer excellent quality and reasonable price items for customers. With us, your safety is guaranteed.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.