Robotic Pick And Place Machine – Neoden8 – Neoden

Robotic Pick And Place Machine – Neoden8 – Neoden Detail:

| Model | NeoDen-K1830 |

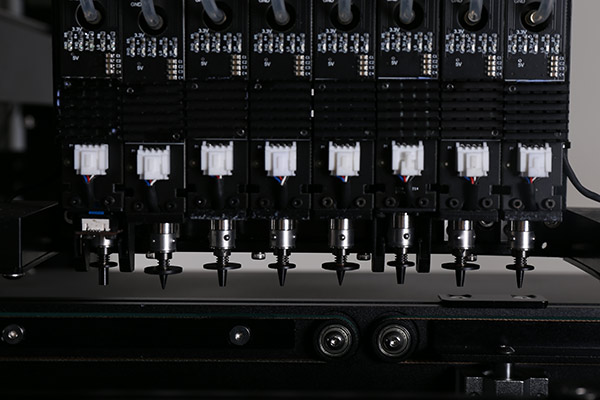

| Nozzle head qty | 8 |

| Reel tape feeder qty max. | 66 |

| Tray feeder qty | 10 |

| PCB size max. | 760*300mm (under single phase) |

| Component available size | 0201 (electric feeder), 0402-1210 |

| IC available | QFP, SSOP, QFN, BGA |

| Placement accuracy | 0.01mm |

| Component available height max. | 18mm |

| Air supply | >0.6MPa |

| Power | 500W |

| Voltage | 220/ 110V |

| Speed max. | 16,000cph |

| Component recognition | Flying vision |

| PCB recognition | High precision mark camera |

| PCB transfer direction | Left→right |

Accuracy:

Closed loop control system can realize a high precision feedback system.

Easy operation:

Realize setting batch feeders’ pick-up position at the same time Realize setting batch feeder’s pick-up height at the same time

Double mark cameras can reach each feeder’s position

Support both electric feeder and pneumatic feeder, feeder selection more flexibly

Advantages compared with N7:

More feeder qty; Internal rails more stable; Higher placement precision

Mechanical structure more reasonable

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for Robotic Pick And Place Machine – Neoden8 – Neoden , The product will supply to all over the world, such as: Lithuania, Jersey, South Africa, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.