Smd Led Manufacturing Machine – SMT assembly machine small PNP machine – Neoden

Smd Led Manufacturing Machine – SMT assembly machine small PNP machine – Neoden Detail:

NeoDen4 SMT assembly machine small PNP machine Video

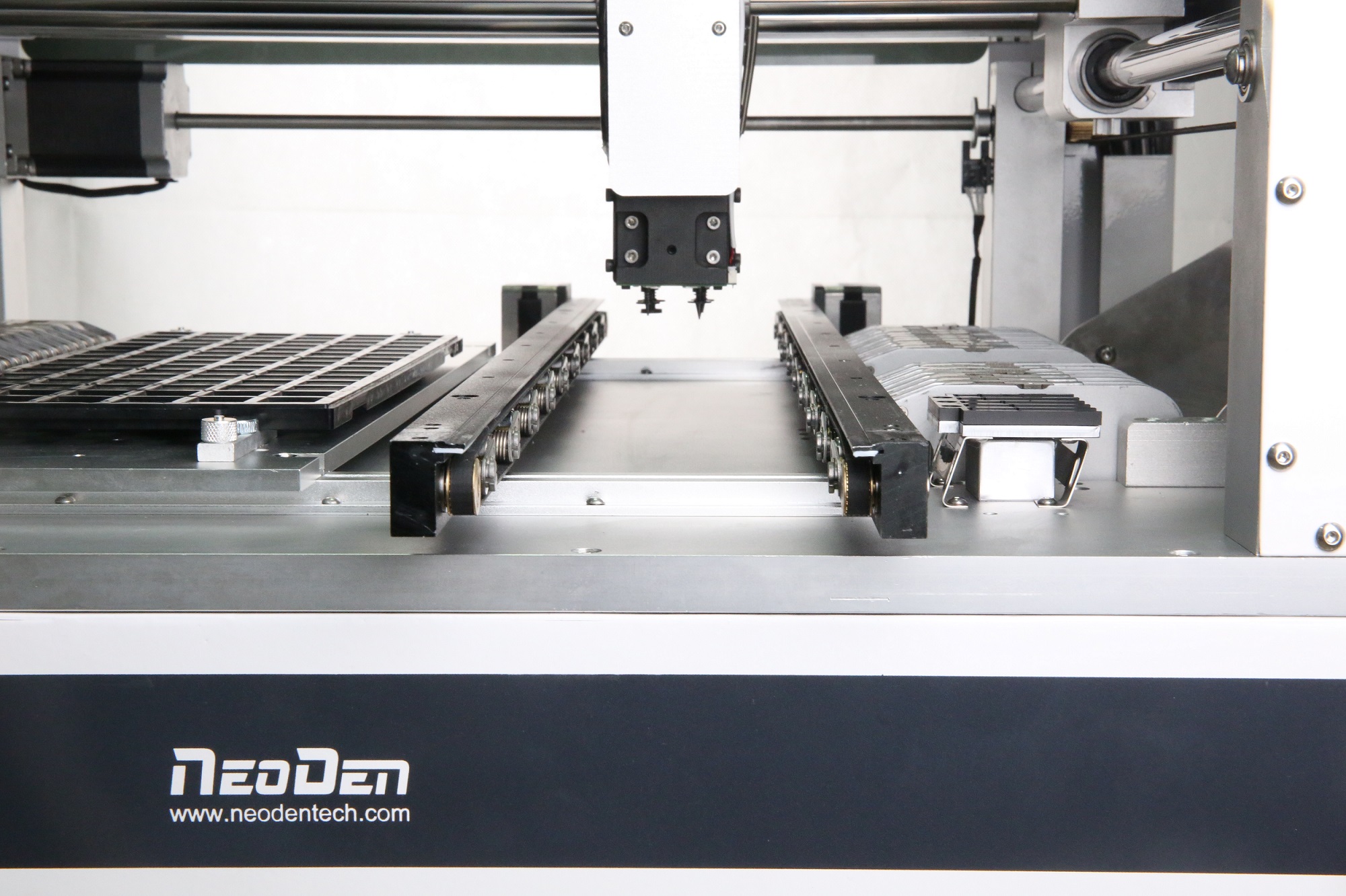

NeoDen4 SMT assembly machine small PNP machine

Specifications

| Product name | NeoDen4 SMT assembly machine small PNP machine |

| Machine Style | Single gantry with 4 Heads |

| Placement Rate | 4000CPH |

| External Dimension | L 680×W 870×H 460mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Details

On-line dual rails

Machines equipped with the auto-loading rail system can accommodate boards from to in width, and in length.

Even when the rail system is installed, any space left over on the table is still available for trays and short tapes.

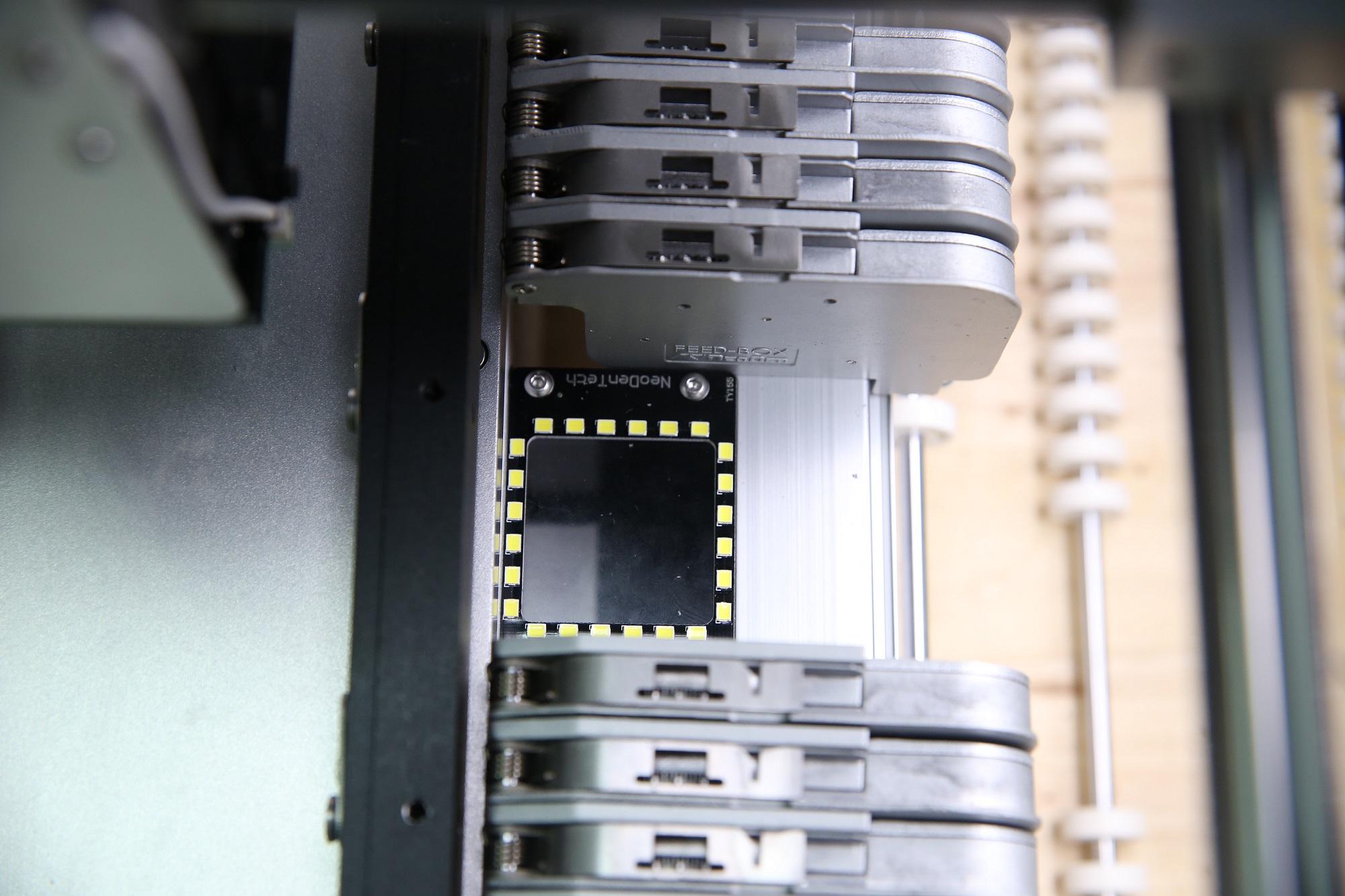

Vision system

Installed with high speed industry CCD cameras, and work with our patented image distortion processing algorithms, enable cameras can recognize and align different components of four nozzles. With the help of upper-camera and down looking camera, they will display the picking process with high definition image.

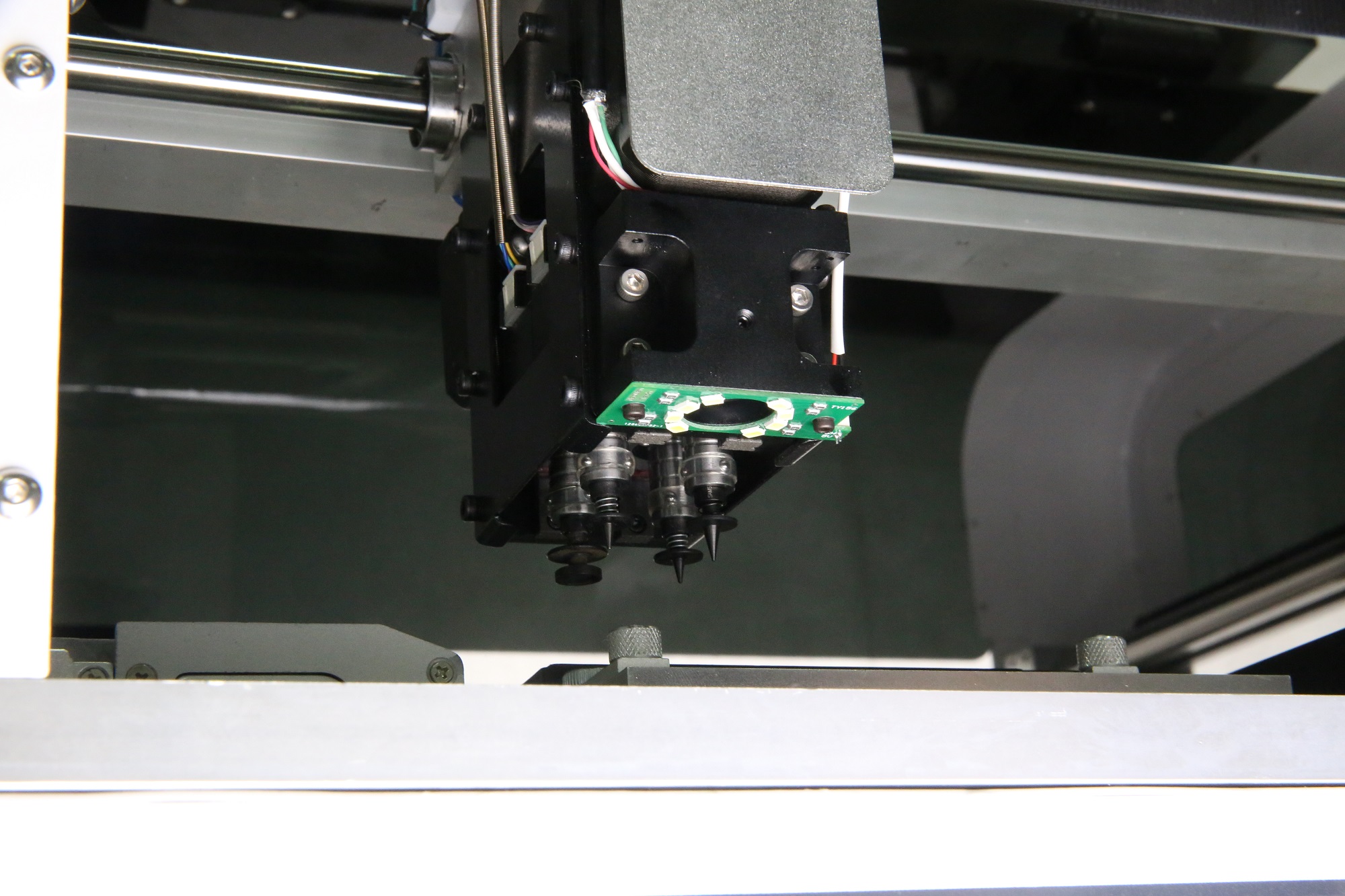

Four high precision nozzles

Electric tape-and-reel feeders, vibration feeders and virtual tray feeders are all supported. Because of the flexibility of the architecture, and the need to work with affordable quantities of parts, short tapes can also be configured on the machine’s bed.

Electric tape-and-reel feeders

The NeoDen4 can accommodate up to 48 8mm tape-and-reel feeders on its left and right rails, and any size feeder (8, 12, 16 and 24mm) can be installed in any combination or order on the left and right sides of the machine.

Packing

Caution

Prepare work

1. Make sure the power cable no damage, no shedding and no loose.

2. Do not put hand in the working area.

Maintenance

1. Repair and calibration should be operated by skilled mechanical technician. When replacing parts, please use the part which are supplied by NeoDen. We are not responsible for any accident result from using nonstandard part.

2. In order to prevent electric shock caused by unskilled operation, the electrical repairs, maintenance (including wiring), should be operated by professional electrician or the technical staff from NeoDen or our distributors.

3. Make sure Bolts – Nuts are tighten after repair, calibration or replacing any part.

Provide one-stop SMT assembly production line

Related products

|

|

|

| Automatic conveyor J12 | Reflow Oven IN6 |

If you need, please feel free to contact us.

FAQ

Q1: How can I buy machine from you?

A: (1) Consult us on line or by e-mail

(2) Negotiate and confirm the final price , shipping , payment method and other terms

(3) Send you the perfroma invoice and confirm your order

(4) Make the payment according to the method put on proforma nvoice

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping

(6) Send your order via express or by air or by sea.

Q2: MOQ?

A: 1 set machine, mixed order is also welcomed.

Q3: Is it hard to use these machines?

A: No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

About us

Exhibition

Certificates

Factory

If you need, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for Smd Led Manufacturing Machine – SMT assembly machine small PNP machine – Neoden , The product will supply to all over the world, such as: Bolivia, Mexico, Colombia, We have more than 100 works in the plant, and we also have a 15 guys work team to service our customers for before and after sales. Good quality is the key factor for the company to stand out from other competitors. Seeing is Believing, want more information? Just trial on its products!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.