One of Hottest for Hot Air Reflow Station - SMT reflow oven machine – Neoden

One of Hottest for Hot Air Reflow Station - SMT reflow oven machine – Neoden Detail:

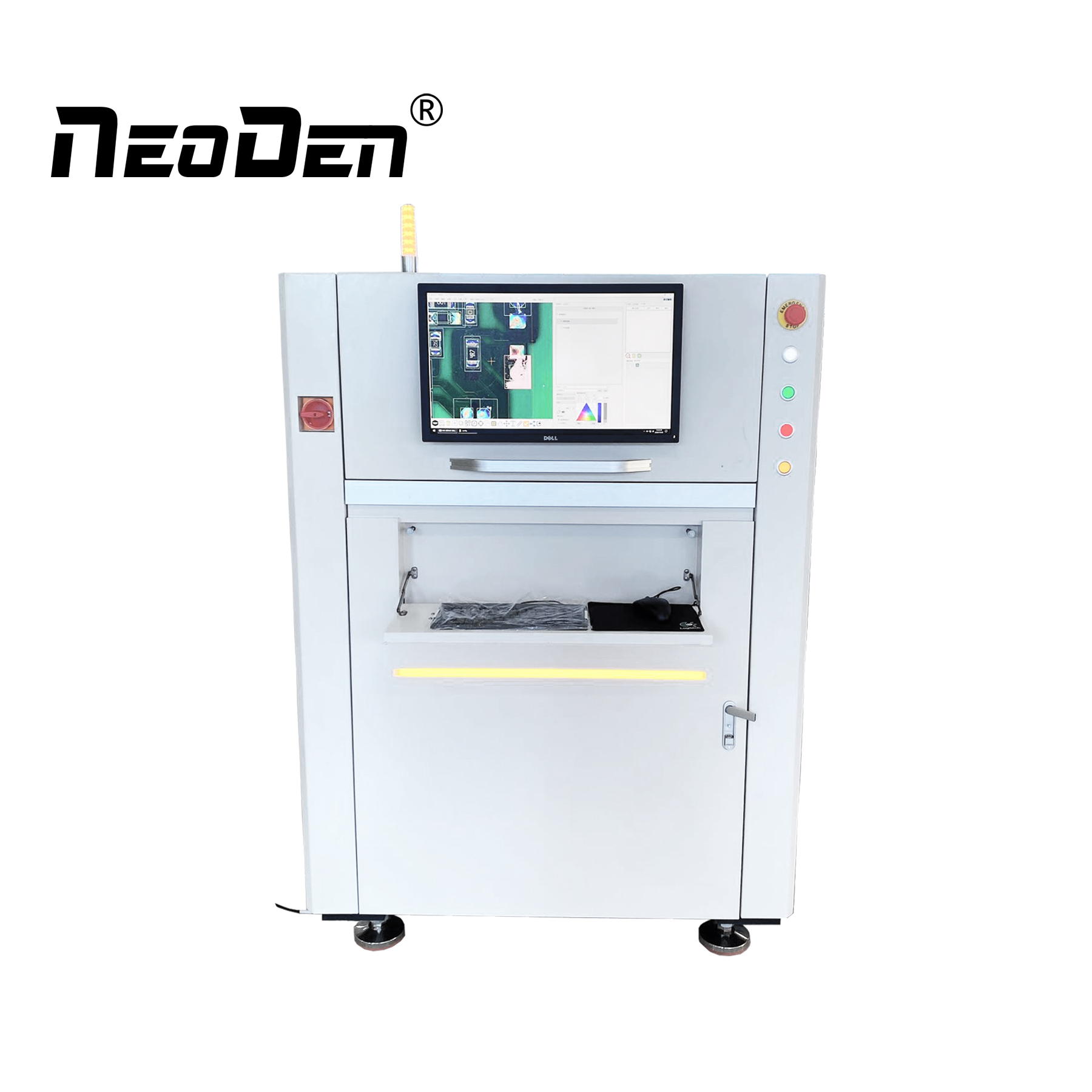

SMT reflow oven machine NeoDen IN6

NeoDen IN6 SMT reflow oven machine is a newly designed, environmentally friendly reflow oven with stable performance. It can achieve full hot-air convection, excellent soldering performance. It has 6 temperature zone, light and compact. Intelligent temperature control with high sensitivity temperature sensor, temperature can be stable within ±0.2°C. It adopts Japan NSK hot air motor bearing and Swiss imported heating wire, which is durable and stable. CE approved, provide authoritative quality assurance.

Provide one-stop SMT assembly production line

Related products

|

|

|

| Stencil printer FP2636 | SMT pick and place machine NeoDen4 | Automatic conveyor J12 |

Specifications

| Product Name | SMT reflow oven machine NeoDen IN6 |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 – 30 cm/min (2 – 12 inch/min) |

| Standard Max Height | 30mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Spotlights

6 zones design, light and compact. Smart control with high sensitivity temperature sensor, the temperature can be stabilized within + 0.2℃. Original high-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature difference is less than 2℃.

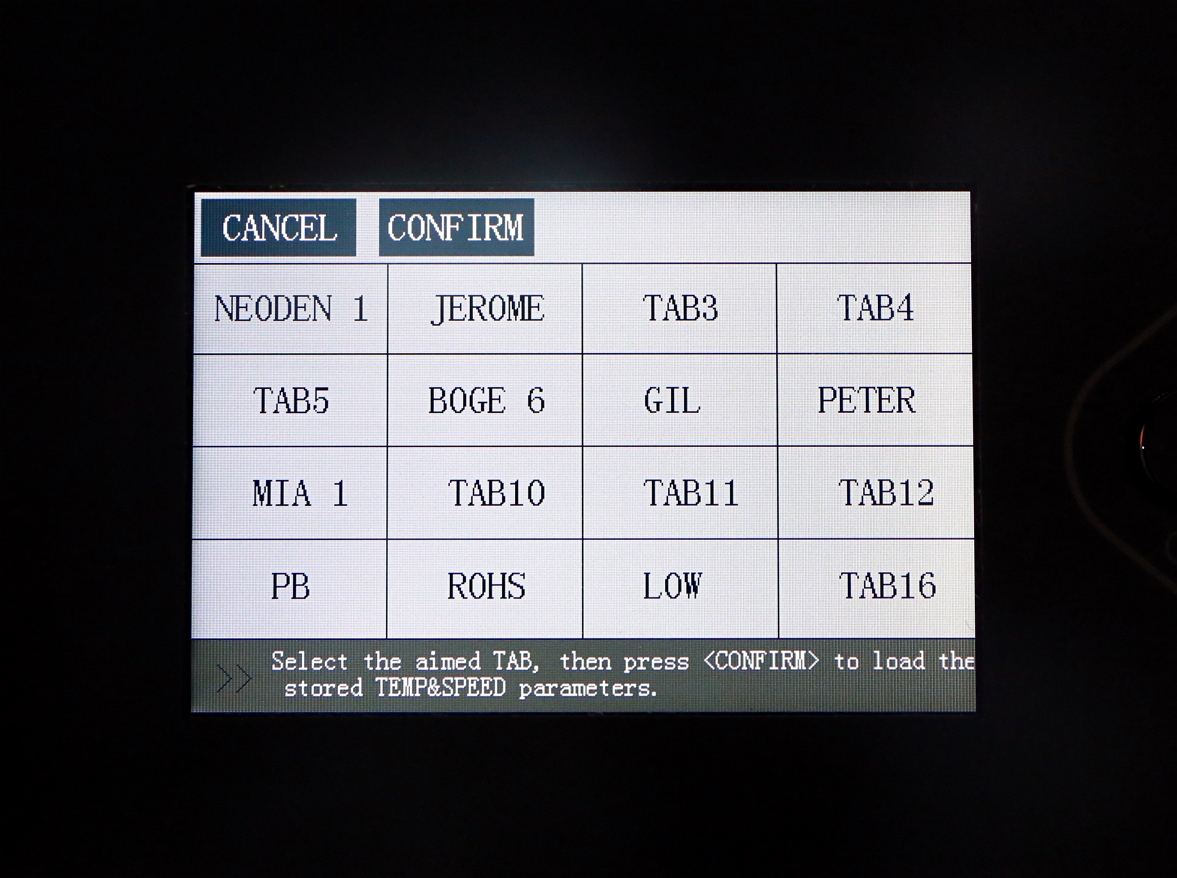

2. 16 working files can be saved

Several working files can be stored, freely switch between Celsius and Fahrenheit, flexible and easy to understand.

PCB soldering temperature curve can be displayed based on real-time measurement.

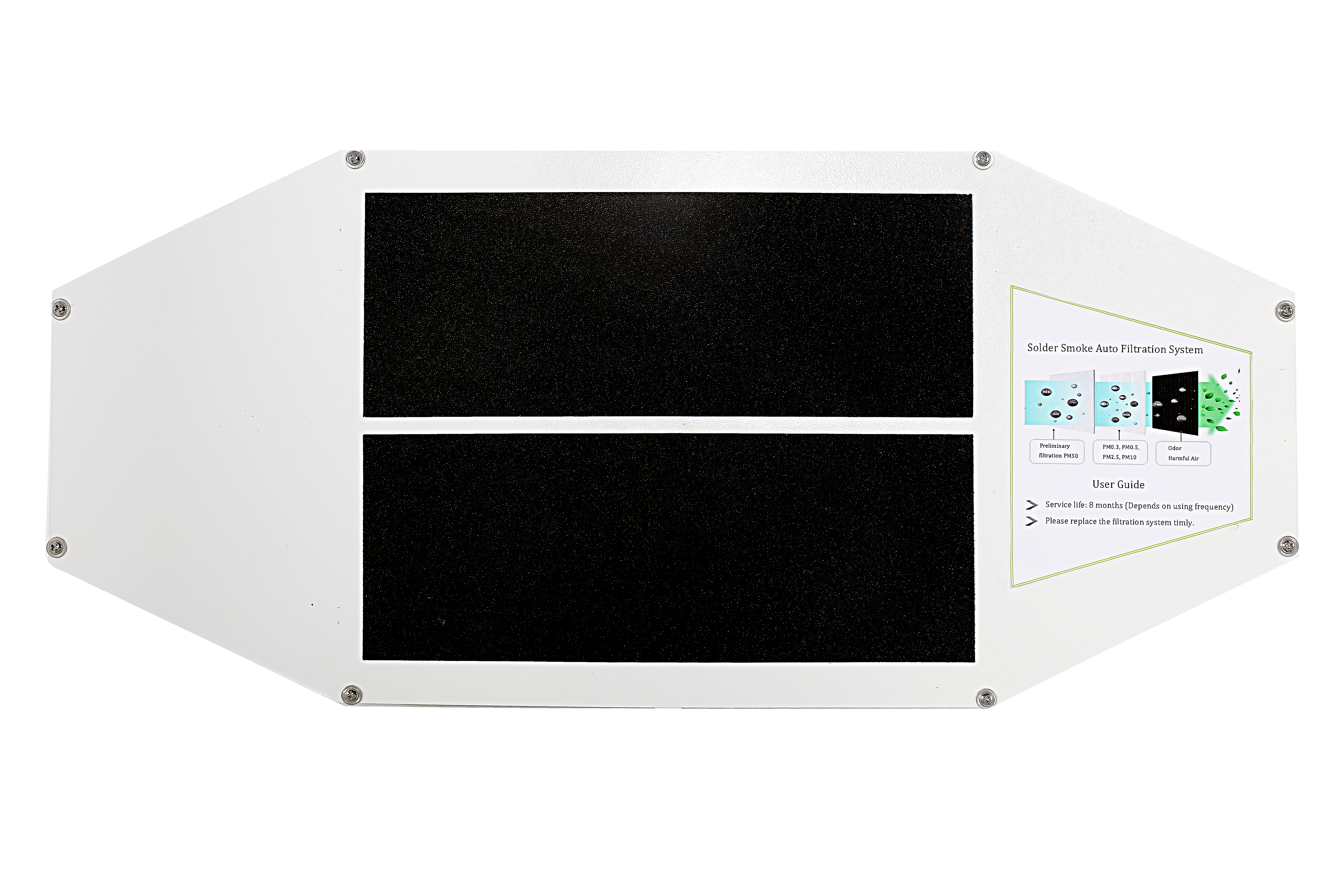

3. Welding smoke filtering system

Original built-in soldering smoke filtering system, elegant appearance and eco-friendly.

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate?

A: Yes. There are English manual and guide video that show you how to use machine.

If there is any doubt in the process of operating the machine, please feel free contact us.

We also provide overseas on-site service.

Q2: What we can do for you?

A: Total SMT Machines and Solution, professional Technical Support and Service.

Q3: How do I pay?

A: My friend, there are many ways. T/T(we prefer this one), Western Union, PayPal, choose your favorite one.

Certificate

Factory

Hangzhou NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere. If you need, please feel free to contact us.

Wbe: www.smtneoden.com

E-mail: info@neodentech.com

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for One of Hottest for Hot Air Reflow Station - SMT reflow oven machine – Neoden , The product will supply to all over the world, such as: Slovakia, Bogota, Netherlands, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.