Reliable Supplier Portable Pick And Place Machine - Pcb Component Placement Machine NeoDen K1830 – Neoden

Reliable Supplier Portable Pick And Place Machine - Pcb Component Placement Machine NeoDen K1830 – Neoden Detail:

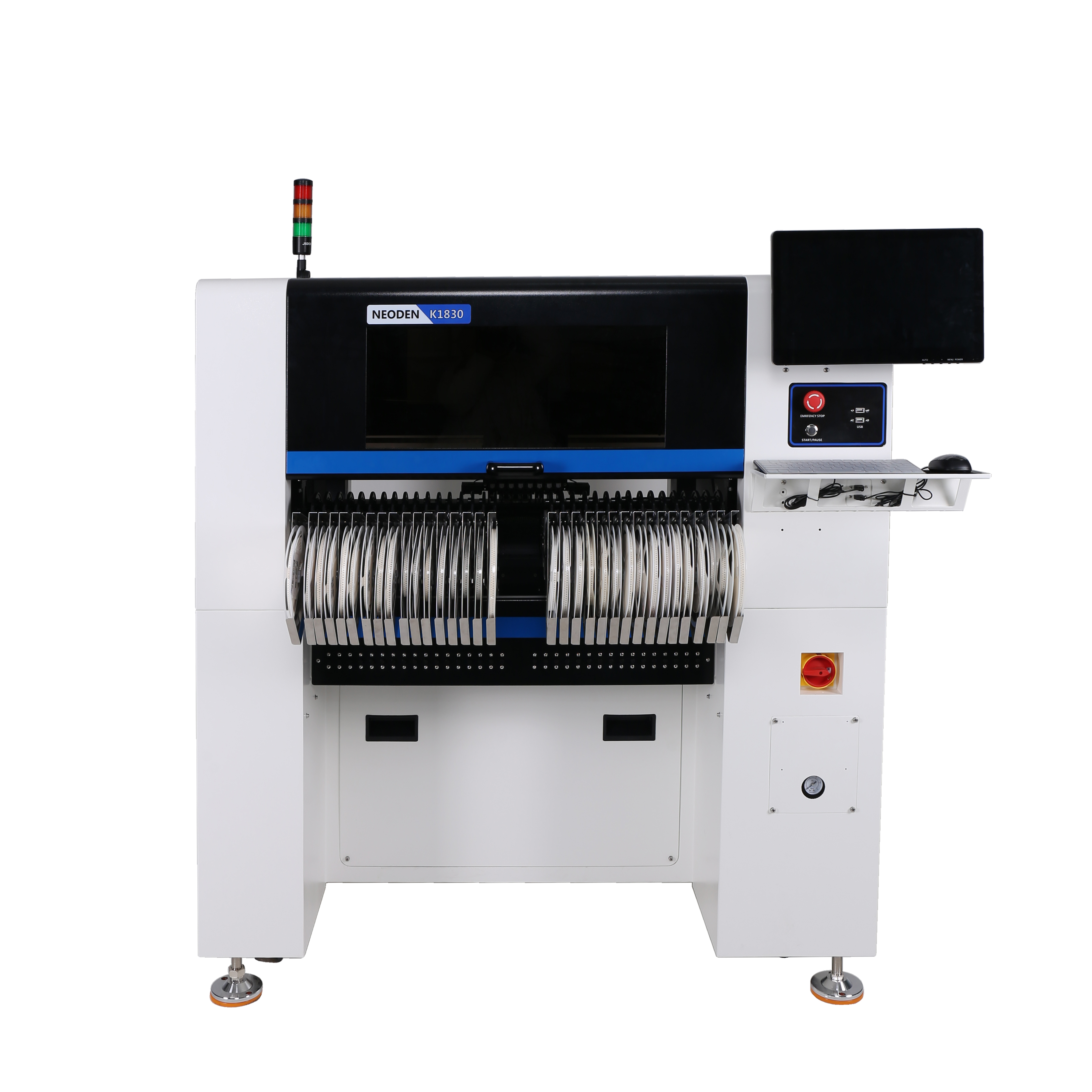

Pcb Component Placement Machine NeoDen K1830

NeoDen K1830 has 8 synchronized nozzles which can make the speed reach to 16000CPH highest.

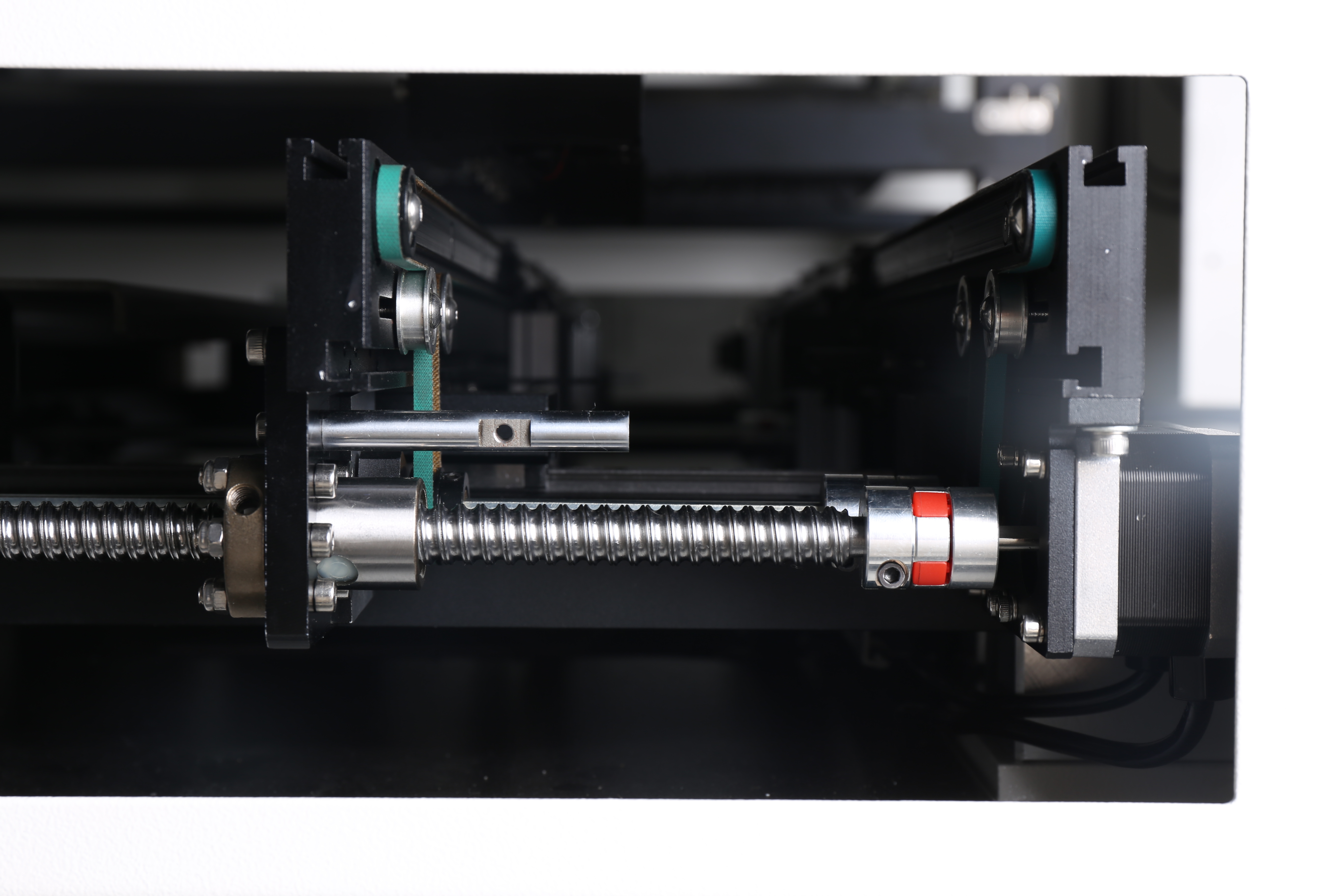

As the second model of production pnp machine, NeoDen improved the machanical structure and functions. With closed loop servo control system and Linux system, the machine is much more stable and efficiency compare to NeoDen7.

NeoDen K1830 is designed for small-medium productional factories. With affordable price and good mounting function, it could be your prior choice for a medium speed production pick and place machine.

Spotlights

1.

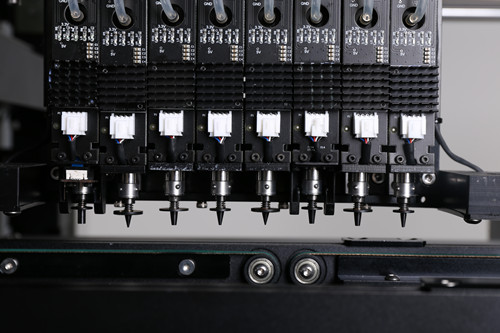

8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed

2.

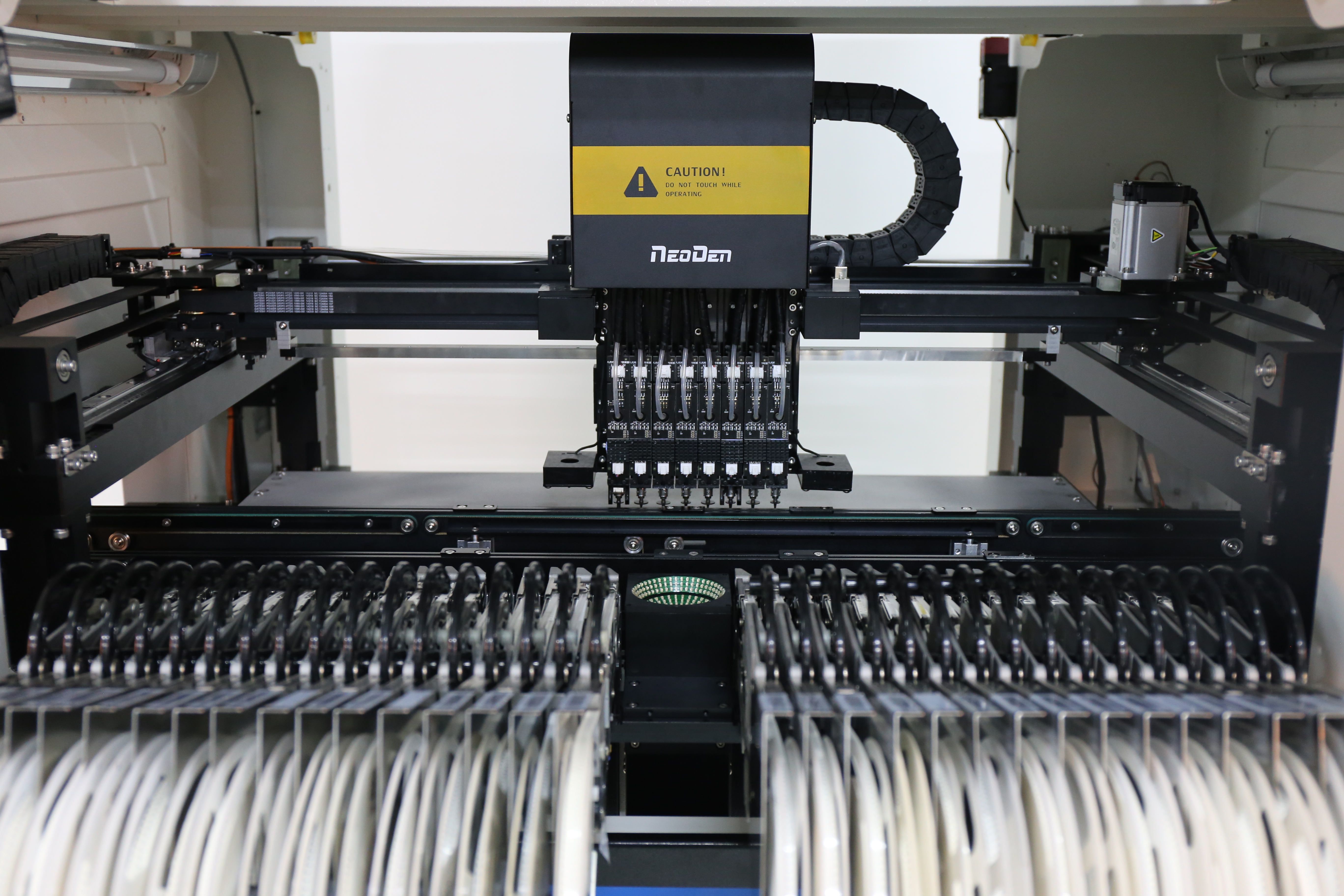

Double mark cameras to reach at extreme end feeders for better calibration

High resolution and high speed component camera system improves the overall speed of the machine

3.

Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy operation and high efficiency

4.

PCB location can be calibrated automatically and promptly,based on the correct and specific placement request

5.

Closed loop Servo control system with feedback makes the machine to function more accurate

6.

Ethernet communication interface for all internal signal travel makes the machine to perform more stable and flexible

Specifications

| Model | NeoDen-K1830 |

| Nozzle head qty | 8 |

| Reel tape feeder qty max. | 66(Electric/Pneumatic) |

| Tray feeder qty | 10 (In Succession) |

| PCB size max. | 540*300mm (under single phase) |

| Component available size | 0201 (electric feeder), 0402-1210 |

| IC available | QFP, SSOP, QFN, BGA |

| Placement accuracy | 0.01mm |

| Component available height max. | 18mm |

| Air supply | >0.6MPa |

| Power | 500W |

| Voltage | 220/ 50HZ & 110V/60HZ |

| Speed max. | 16,000cph |

| Component recognition | High Resolution Flying Vision Camera System |

| PCB Fiducial Recognition | High Precision Mark Camera |

| PCB Loading | Synchronized 3 Stages Internal Conveyor |

| PCB transfer direction | Left→right |

| Net Weight | 280kgs |

| Gross Weight | 360kgs |

| Machine Dimensions | 1288×1062×1291mm |

| Packing Dimensions | 1420×1220×1665mm |

Certificate

Factory

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

With this motto in mind, we've got become among essentially the most technologically innovative, cost-efficient, and price-competitive manufacturers for Reliable Supplier Portable Pick And Place Machine - Pcb Component Placement Machine NeoDen K1830 – Neoden , The product will supply to all over the world, such as: Libya, Atlanta, Cambodia, We have to continue to uphold the "quality, comprehensive, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class products and improve service welcome overseas customers patrons.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.