Reliable Supplier Portable Pick And Place Machine - Surface mount soldering equipment – Neoden

Reliable Supplier Portable Pick And Place Machine - Surface mount soldering equipment – Neoden Detail:

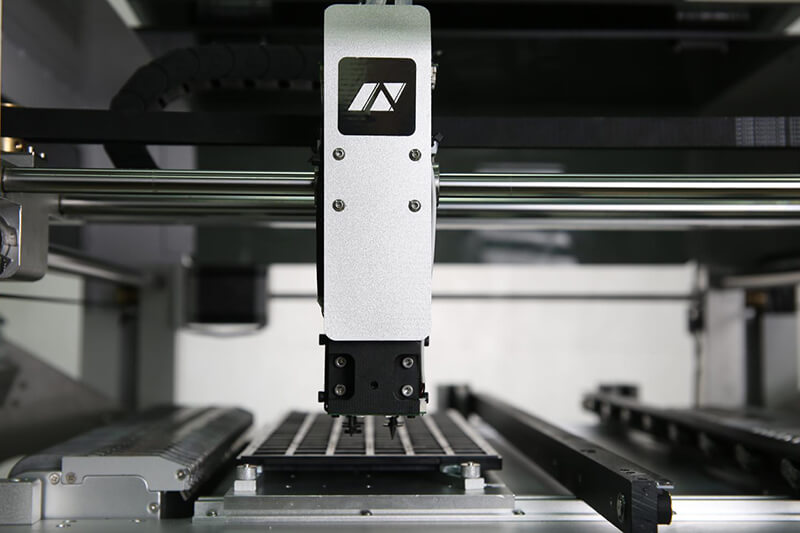

Surface mount soldering equipment NeoDen4 is components flexibility, PCB and production flexibility.

NeoDen4 surface mount soldering equipment MICRON high speed industry CCD cameras, the mounting head is designed in a suspended, fully symmetric and high degree of coupling way, ensure it can mount components with higher space, more gentle and more efficient.

Specifications

| Product name | NeoDen4 surface mount soldering equipment |

| Machine Style | Single gantry with 4 Heads |

| Placement Rate | 4000CPH |

| External Dimension | L 680×W 870×H 460mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Spotlights

1. On-line dual rails

NeoDen independent research and development on-line dual rails:

A.continuous automatic feeding the boards during the mounting

B.set the feeding position at anywhere shorten the mounting route

C.we have leading technology in SMT industry what Mark point relocated technology, can mount overlong boards easily

2. Four precision heads

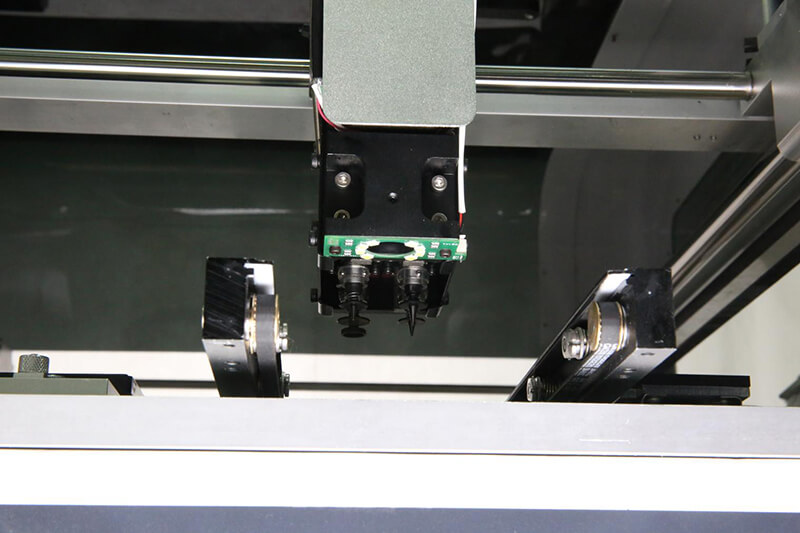

The mounting head is designed in a suspended, fully symmetric and high degree of coupling way, ensure it can mount components with higher space, more gentle and more efficient. Surprisedly, we design and equip with four high precision nozzles.They can mount at the same time with 360 degrees rotation at -180 to 180.

3. Auto Electronic Feeders

Our brand new patented electronic feeders adopts new technique—feeding error corrections, which smooths the feeding and picking. Meanwhile, Neoden 4 has increased the maximum feeders from 27 to 48pcs.

4. Vision system

Installed with high speed industry CCD cameras,and work with our patented image distortion processing algorithms,enable cameras can recognize and align different components of four nozzles.With the help of upper-camera and down looking camera, they will display the picking process with high definition image.Multiply efficiency while ensure accuracy.

Our service

1. Provide video tutorial after purchasing the product

2. 24-hour online support

3. Professional after-sales technical team

4. Free broken parts(Within 1 Year warranty)

Provide one-stop SMT assembly production line

Related products

|

|

|

| Automatic conveyor J12 | Reflow Oven IN6 |

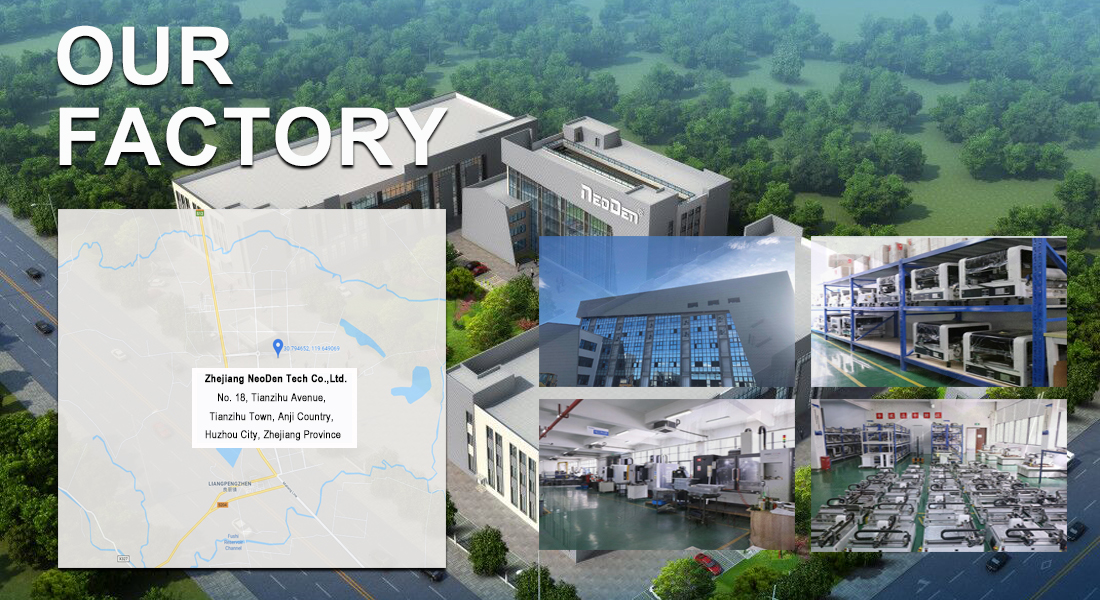

Factory

Hangzhou NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We have our own R & D team and own factory, taking advantage of our own rich experienced R&D, well trained production, won great reputation from the world wide customers.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere.

Certificates

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate?

A: Yes. There are English manual and guide video that show you how to use machine.

If there is any doubt in the process of operating the machine, please feel free contact us.

We also provide overseas on-site service.

Q2: Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line and other SMT Products.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Reliable Supplier Portable Pick And Place Machine - Surface mount soldering equipment – Neoden , The product will supply to all over the world, such as: Ukraine, Muscat, Rio de Janeiro, Merchandise have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the items performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we'll undoubtedly do our very best to support your business in China.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!