Small Pick and Place Machine NeoDen

Small Pick and Place Machine NeoDen

NeoDen3V

Small Pick and Place Machine

2 Heads, ±180° rotation head system

Small volume, low power

High speed and accuracy

Stable performance and easy operation

Introduction

NeoDen 3V small pick and place machine are desktop automatic pick and place machines especially developed for research laboratories and small medium manufacturing enterprises however it will also be suitable for the serious hobbyist. These automatic pick and place machines are suitable for small batch production, laboratory research and development, product sample trials, LED SMT processing and other similar processes.

Specification

| Product Name | Small Pick and Place Machine NeoDen |

||

| Machine Style | Single Gantry with 2 heads | Model | NeoDen 3V-Advanced |

| Placement Rate | 3,500CPH Vision on/5,000CPH Vision off | Placement Accuracy | +/-0.05mm |

| Feeder Capacity | Max Tape Feeder: 44pcs (All 8mm width) | Alignment | Stage Vision |

| Vibration Feeder: 5 | Component Range | Smallest Size: 0402 | |

| Tray Feeder: 10 | Biggest Size: TQFP144 | ||

| Rotation | +/-180° | Max Height: 5mm | |

| Electricity Supply | 110V/220V | Max Board Dimension | 320x390mm |

| Power | 160~200W | Machine Size | L820×W680×H410mm |

| Net Weight | 60Kg | Packing Size | L1010×W790×H580 mm |

Detail

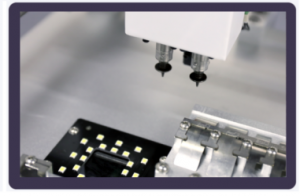

2 Mounting Heads

Full Vision 2 heads system

±180° rotation satisfy the need of wide range components

Patented Automatic Peel-box

Feeder Capacity: 44*Tape feeder(all 8mm),

5*Vibration feeder, 10* IC Tray feeder

Flexible PCB positioning

Using PCB support bars and pins,

wherever to put the PCB, whatever the shape of PCB.

Integrated Controller

More stable performance and easier to do maintenance.

Click on the picture below to jump to the appropriate product:

Mirror Board

Mirror board includes row panelized PCB and column panelized PCB.

Row panelized: several same PCBs are arranged in horizontal direction, and the nearby rows are mirrored

Column panelized: several same PCBs are arranged in vertical direction, and the nearby columns are mirrored

Working Environment

1. Do not use machine in a noisy environment, such as high frequency welding machine.

2. Do not use machine if the power supply voltage exceed the rated voltage ± 10%.

Do not use machine and pull the plug when thunder to avoid any accident caused by damaged electrical component.

About us

Factory

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

Owned the own machining center, skilled assembler, tester and QC engineers, to ensure the strong abilities for NeoDen machines manufacturing, quality and delivery.

40+ global partners covered in Asia, Europe, America, Oceania and Africa, to successfully serve 10000+ users in all of the world, to ensure the better and faster local service and prompt response.

Certification

Exhibition

FAQ

Q1: Do you provide software updates?

A: Customers who buy our machine, we can offer free upgrades software for you.

Q2: This is the first time I use this kind of machine, is it easy to operate?

A: Yes. There are English manual and guide video that show you how to use machine.

If there is any doubt in the process of operating the machine, please feel free contact us.

We also provide overseas on-site service.

Q3: What’s your tem of the delivery?

A: Our ordinary delivery term is FOB Shanghai.

We also accept EXW, CFR, CIF, DDP, DDU etc. We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

If you need, please feel free to contact us for more information!

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.