SMT AOI SPI Machine

NeoDen ND S1 SMT AOI SPI Machine

Product Overview

Brand

Country/Region of Manufacture

Camera Feature

Min PCB Size

Max PCB Size

NeoDen

China

3D raster camera(double is optional)

50mm×50mm

500mm×460mm

Model

Application

Max test height

Transfer speed

External sizes

ND S1

Solder Paste Inspection

400 μm

1500mm/s (MAX)

L1090×W1290×H1534mm

Features

SMT AOI SPI machine is used for solder paste inspection and is placed behind the SMT solder printer.

SMT AOI SPI machine mainly detects the thickness, area, size and volume of the solder paste.

Analyze the solder paste to see if there is any continuous tin, collapse and so on.

Judge whether the size, dimension, height, thickness and other parameters of the solder paste are suitable, and prepare for the SMD.

Details

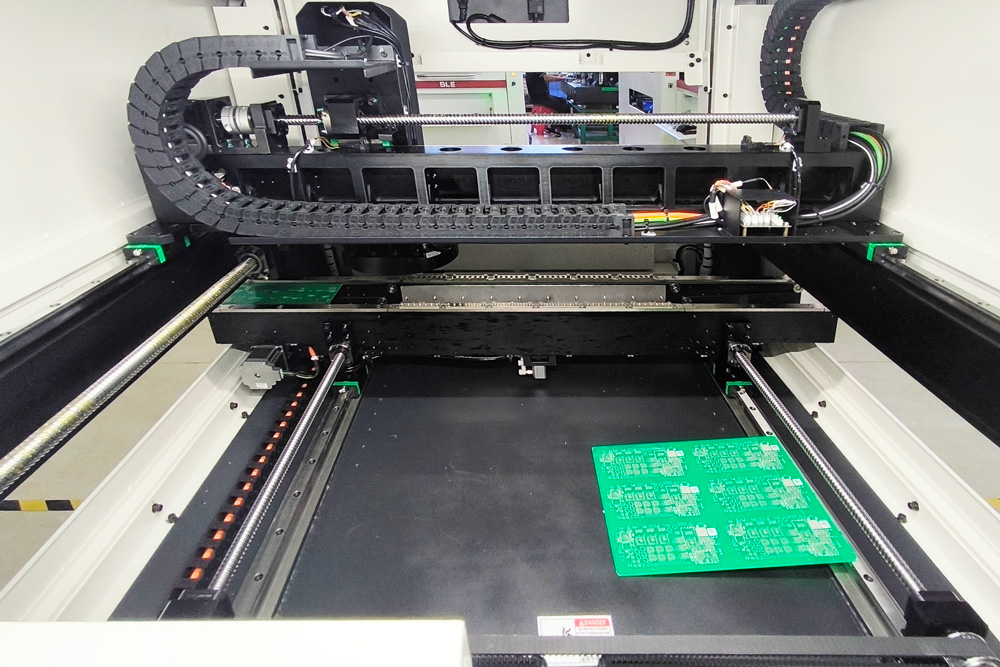

Platform

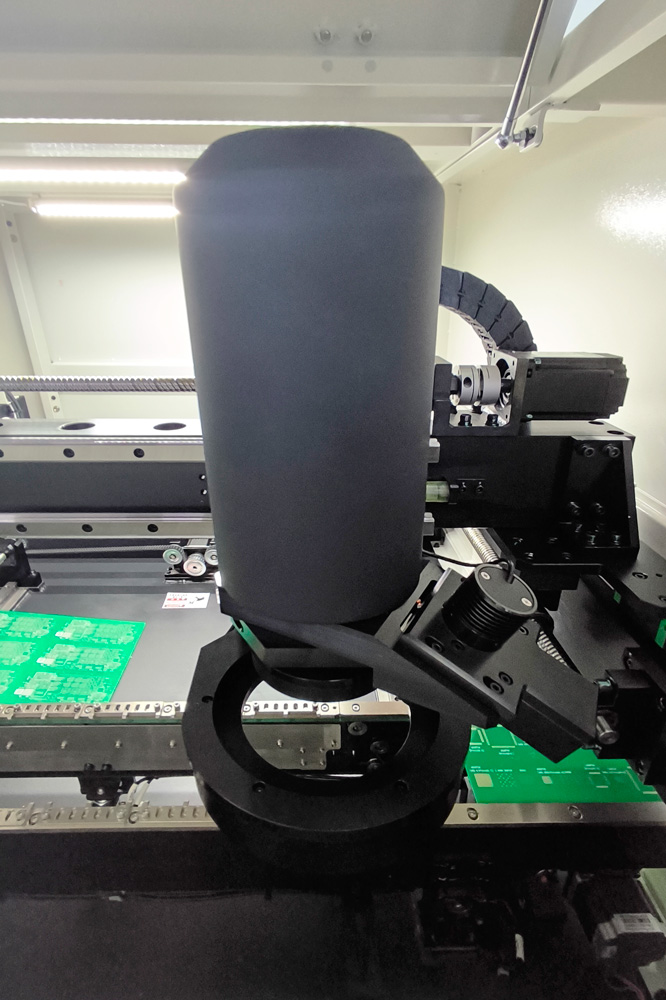

Camera

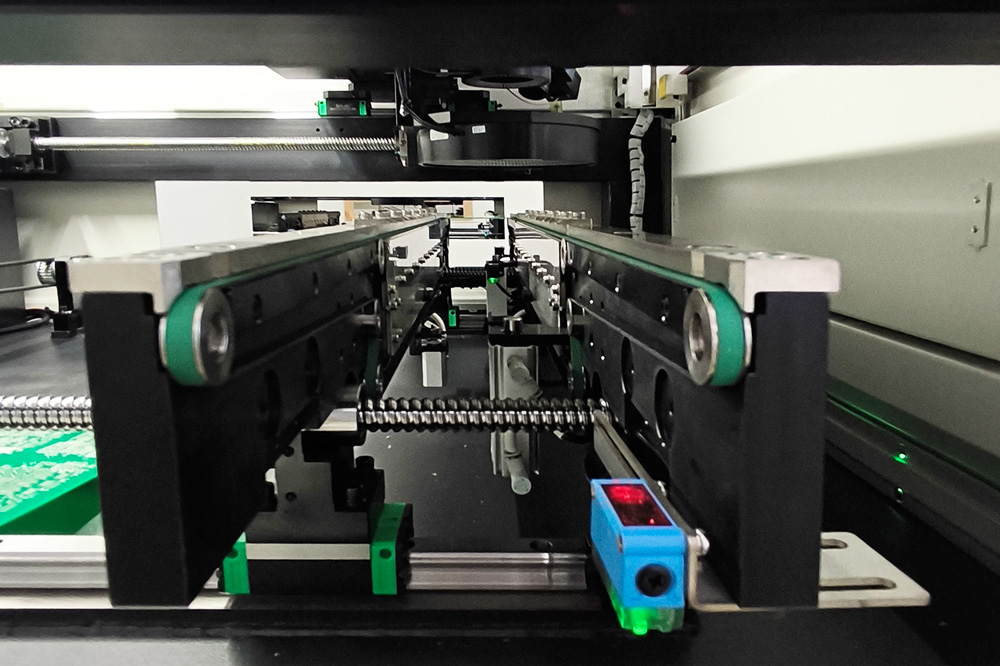

Rail

Air pressure gauge

Specification

| PCB transfer system | 900±30mm | Min PCB size | 50mm×50mm |

| Max PCB size | 500mm×460mm | PCB thickness | 0.6mm~6mm |

| Plate edge clearance | up: 3mm, down: 3mm | Transfer speed | 1500mm/s (MAX) |

| Plate bending compensation | <2mm | Driver equipment | AC servo motor system |

| Setting accuracy | <1 μm | Moving speed | 600mm/s |

Software System

Operation system: Windows 7 Ultimate 64bit

1. Idetification system

Feature:3d raster camera(double is optional)

Operate interface: Graphical programming, easy to operate, Chinese and English system switch over

Interface: 2D AND and 3D truecolor image

MARK: Can choose 2 commom mark point

2. Programe

Support gerber, CAD input, offline and manual program

3. SPC

Offline SPC: Support

SPC Report: Anytime Report

Control Graphic: Volume, area, height, offset

Export content: Excel, image (jpg, bmp)

Our Service

1. Good knowledge on different market can meet special requirements.

2. Real manufacturer with our own factory located in Huzhou, China.

3. Strong professional technical team ensure to produce the top quality products.

4. Special cost control system ensure to provide the most favorable price.

5. Rich experience on SMT area.

Provide one-stop SMT assembly production line

FAQ

Q1. Is it hard to use NeoDen SMT AOI SPI machine?

A. No, not hard at all.

There are English manual and guide video that show you how to use NeoDen S1.

If there is any doubt in the process of operating the NeoDen SMT SPI machine, please feel free contact us.

We also provide overseas on-site service and life time after-sales online support.

Q2. What about the lead time for SMD production line?

A. Honestly, it depends on the machines quantity.

Always 7-20 days based on general order.

Q3. What products you sell?

A. Our company deal in the following products

SMT line equipments

solder stencil printer, SMT AOI machine, SMT SPI machine, SMT X-Ray machine, reflow oven

SMT accessories

Feeders, Feeder parts, SMT nozzles

About Us

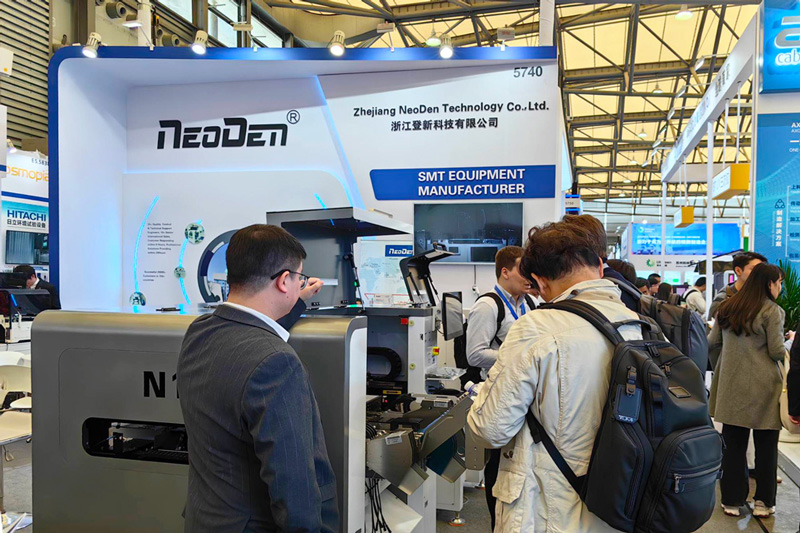

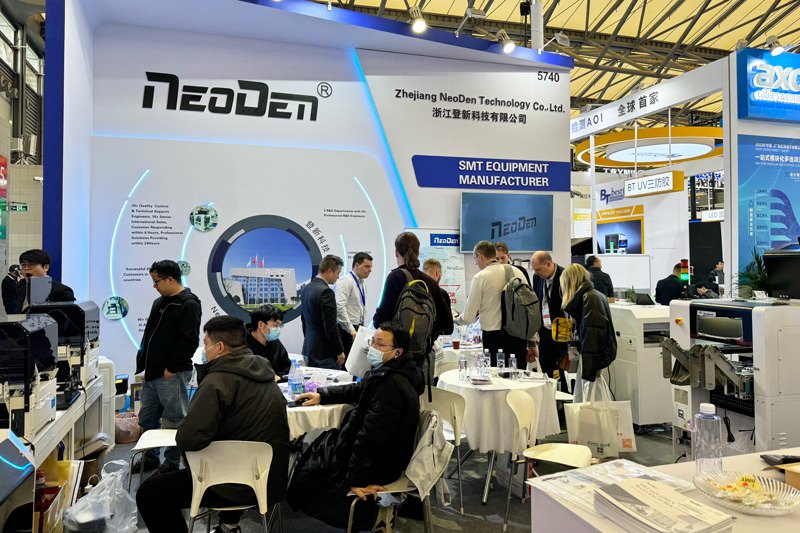

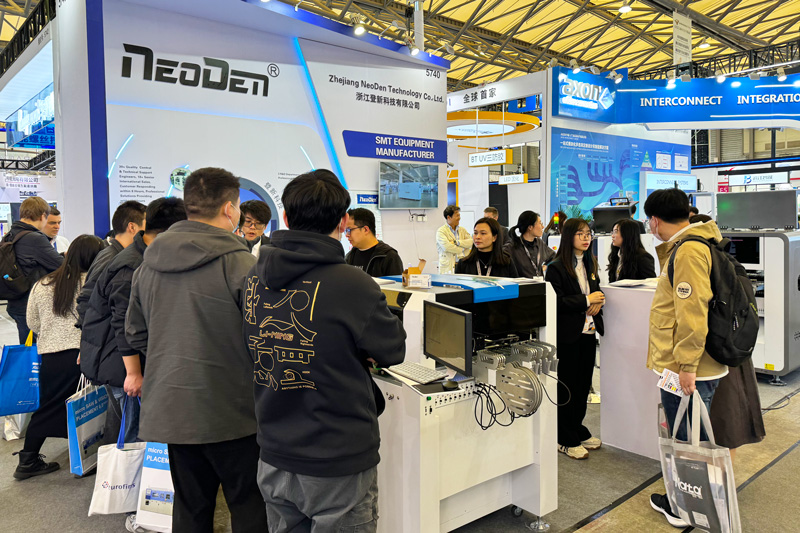

Exhibition

Certification

Our Factory

Company Profile

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.