SMT automatic pick and place machine

NeoDen K1830 SMT automatic pick and place machine video

NeoDen K1830 SMT automatic pick and place machine

Features

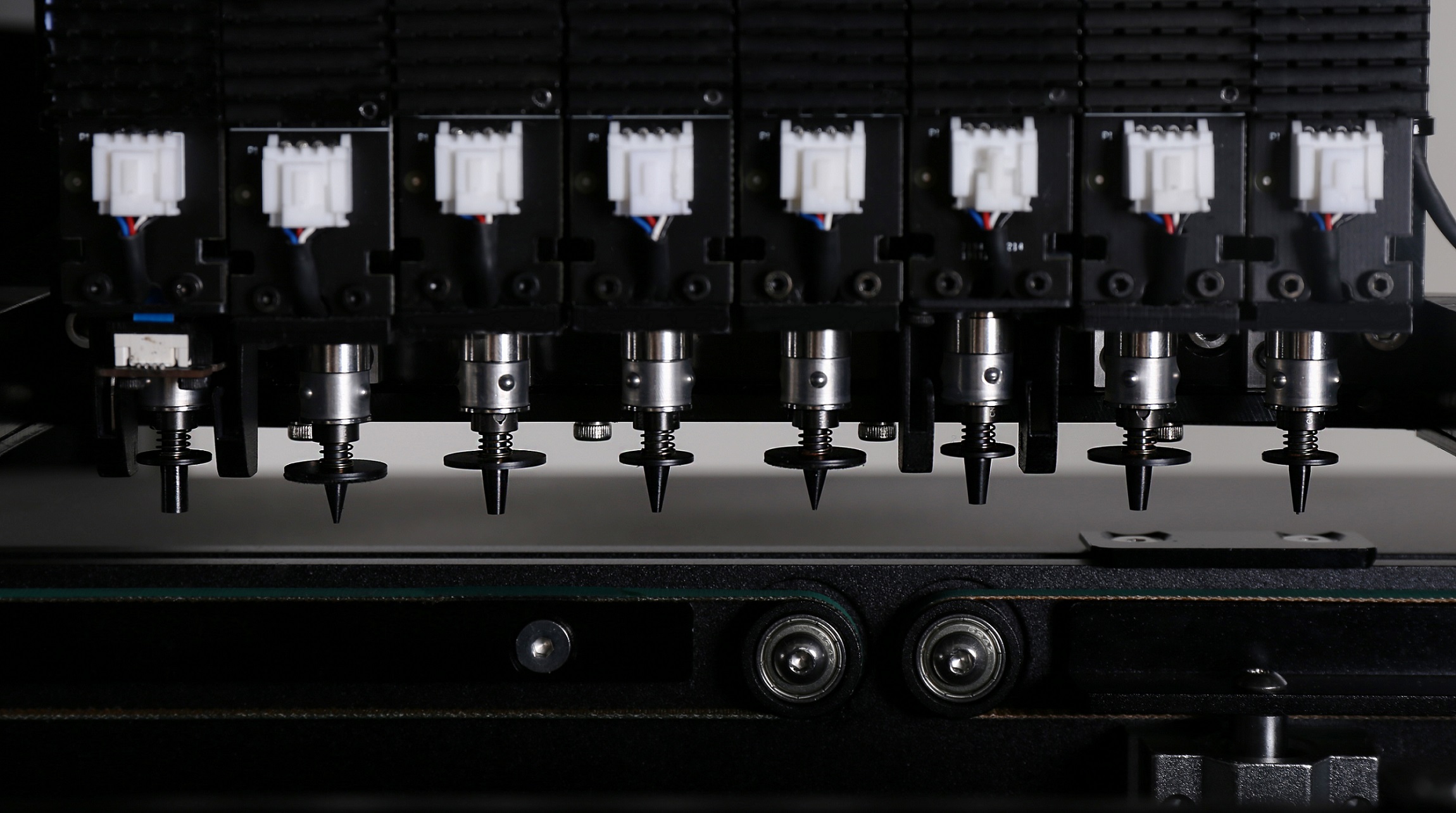

Head

8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed

System

Machine runs on highly stable and secure Linux operating system

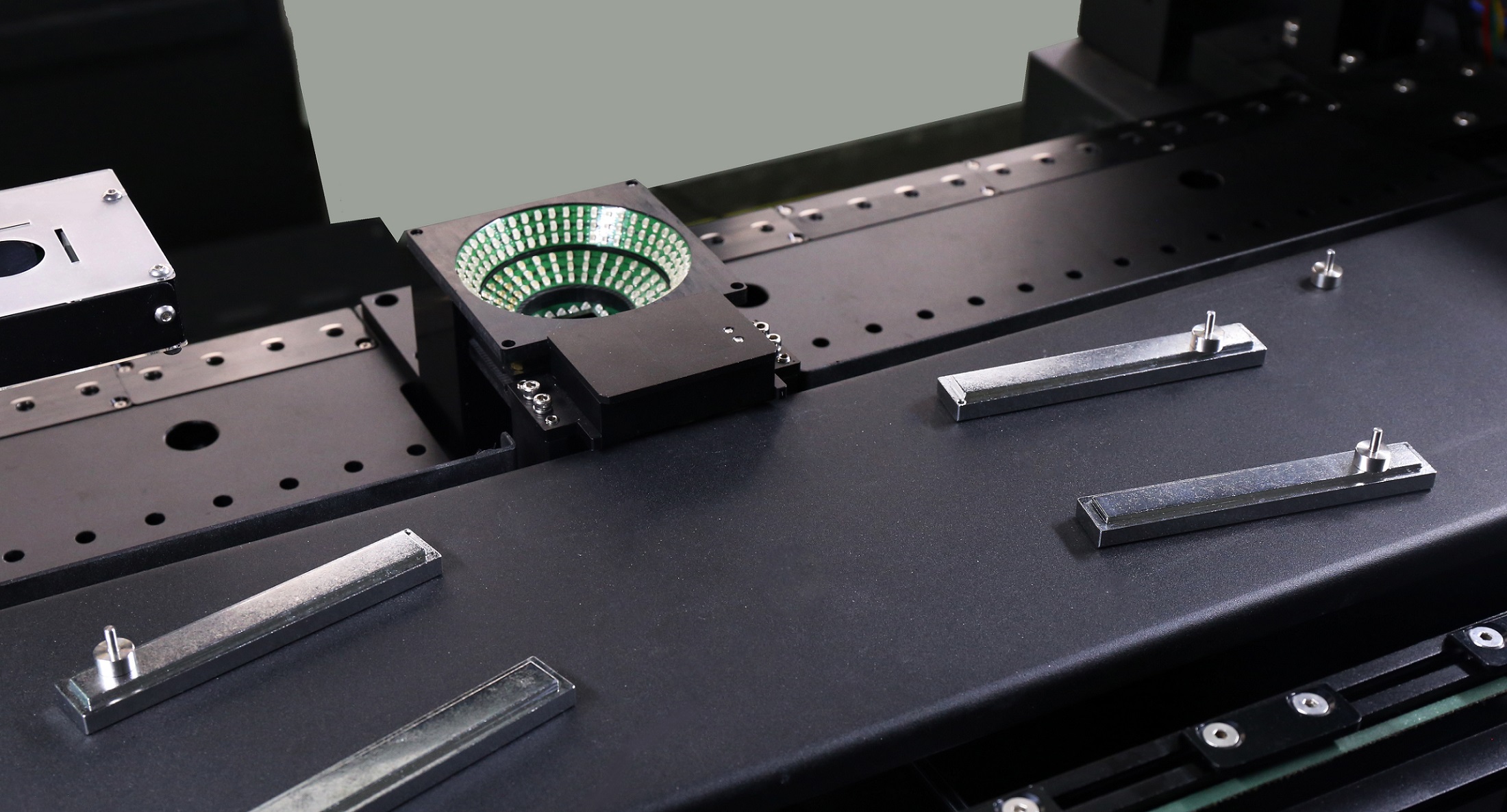

Camera

Double mark cameras to reach at extreme end feeders for better calibration

Interface

Ethernet communication interface for all internal signal travel makes the machine to perform more

stable and flexible

Feeder

Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy

operation and high efficiency

Calibrate

PCB location can be calibrated automatically and promptly,based on the correct and specific placement

request

Product Detail

8 high speed nozzles

1-8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed.

2-Machine runs on highly stable and secure Linux operating system.

Vision system

1-Double mark cameras to reach at extreme end feeders for better calibration.

2-High resolution and high speed component camera system improves the overall speed of the machine.

66 Reel tape feeders

1-Closed loop Servo control system with feedback makes the machine to function more accurate.

2-Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy operation and high efficiency.

Description

| Product name | NeoDen K1830 SMT automatic pick and place machine |

| Nozzle Q’ty | 8 |

| Reel Tape Feeder Q’ty(Max) | 66 (Electric / Pneumatic) |

| IC Tray Feeder Q’ty | 10 (In Succession) |

| Max PCB size | 540*300mm(In Single Step) |

| Smallest Component Size | 0201(Electric Feeder Available) |

| IC Packages | QFP, SSOP, QFN, BGA |

| Placement accuracy | 0.01mm |

| Max Component Height | 18mm |

| Max Placement Speed | 16,000CPH |

| Component Recognition | High Resolution Flying Vision Camera System |

| PCB Fiducial Recognition | High Precision Mark Camera |

| PCB Loading | Synchronized 3 Stages Internal Conveyor system |

| PCB Transfer Direction | Left→Right |

| Air Supply | >0.6MPa |

| Power | 500W |

| Voltage | 220V/50HZ & 110V/60HZ |

| Net Weight | 280kgs |

| Gross Weight | 360kgs |

| Machine Dimensions | 1288×1062×1291mm(Without Tri-color Light) |

| Packing Dimensions | 1420×1220×1665mm |

Notes

(1) Do not touch the surface to board to avoid damaging the printed solder paste.

(2) When the error message occurs, please check out and solve it a.s.a.p.

(3) Once reloading the component during production, pay attention to the model, specification, polarity and direction of components.

(4) Clear the reject box timely to avoid wasted materials stacked too high to damage the mount head.

Our service

We are in a good position not only to supply you high quality pnp machine , but also the excellent after sales service.

Well-trained engineers will offer you any technical support.

10 engineers powerful after-sales service team can respond customers queries and enquiries within 8 hours, professional solutions can be offered within 24 hours both workday and holidays.

If you need, please don't hesitate to send your inquiry.

Provide one-stop SMT assembly production line

FAQ

Q1: How can I buy machine from you?

A: (1) Consult us on line or by e-mail

(2) Negotiate and confirm the final price , shipping , payment method and other terms

(3) Send you the perfroma invoice and confirm your order

(4) Make the payment according to the method put on proforma nvoice

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping

(6) Send your order via express or by air or by sea.

Q2: Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line and other SMT Products.

Q3: What's the way of shipping?

A: These are all heavy machines; we suggest you use cargo ship. But components for mending the machines, air transportation would be fine.

About us

Exhibition

Certification

Factory

If you need, please don't hesitate to send your inquiry.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.