SMT Mini Pick and Place Machine

SMT Mini Pick and Place Machine

NeoDen3V

SMT Mini Pick and Place Machine

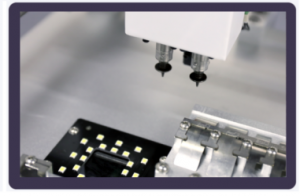

2 Heads, ±180° rotation head system

Small volume, low power

High speed and accuracy

Stable performance and easy operation

Introduction

NeoDen 3V SMT mini pick and place machine compared with the previous version TM245P,

NeoDen 3V adopts a high-definition camera that could mount most kinds of components including micro chips like 0402, fine-pitch ICs like QFN and so on;

and with high speed and accuracy, small volume, low power, stable performance and easy operation,

NeoDen 3V committed to create the greatest value and try to fulfill all demands for customers in the actual production.

Specification

| Product Name | SMT Mini Pick and Place Machine |

||

| Machine Style | Single Gantry with 2 heads | Model | NeoDen 3V-Advanced |

| Placement Rate | 3,500CPH Vision on/5,000CPH Vision off | Placement Accuracy | +/-0.05mm |

| Feeder Capacity | Max Tape Feeder: 44pcs (All 8mm width) | Alignment | Stage Vision |

| Vibration Feeder: 5 | Component Range | Smallest Size: 0402 | |

| Tray Feeder: 10 | Biggest Size: TQFP144 | ||

| Rotation | +/-180° | Max Height: 5mm | |

| Electricity Supply | 110V/220V | Max Board Dimension | 320x390mm |

| Power | 160~200W | Machine Size | L820×W680×H410mm |

| Net Weight | 60Kg | Packing Size | L1010×W790×H580 mm |

Detail

2 Mounting Heads

Full Vision 2 heads system

±180° rotation satisfy the need of wide range components

Patented Automatic Peel-box

Feeder Capacity: 44*Tape feeder(all 8mm),

5*Vibration feeder, 10* IC Tray feeder

Flexible PCB positioning

Using PCB support bars and pins,

wherever to put the PCB, whatever the shape of PCB.

Integrated Controller

More stable performance and easier to do maintenance.

Click on the picture below to jump to the appropriate product:

PCB Angle Correction

PCB angle will influence the accuracy of mounting.

The angle more closer to 0 degree the better, and the angel deviation need to be within 1 degree.

The angle of PCB is generated according to panelized PCB coordinates, but we can also adjust the angle by manual.

Click” PCB angle” button, according to the index of machine to choose two points, then a new PCB angle will be generated. ( Note, the two points need to be in one vertical or horizontal line)

Under panelized PCB mode, “ PCB angle” is locked.

You need to correct from panelized PCB to single PCB( 1*1), after confirm the PCB angle, you can change back to panelized PCB model.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere.

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

Certification

Exhibition

FAQ

Q1: Which payment form you can accept?

A: T/T, Western Union, PayPal etc.

We accept any convenient and swift payment term.

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry.

If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: What is your main market?

A: All over the world.

If you need, please feel free to contact us for more information!

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.