SMT Pick and Place Machine Line SMT chip mounter

SMT Pick and Place Machine Line Video

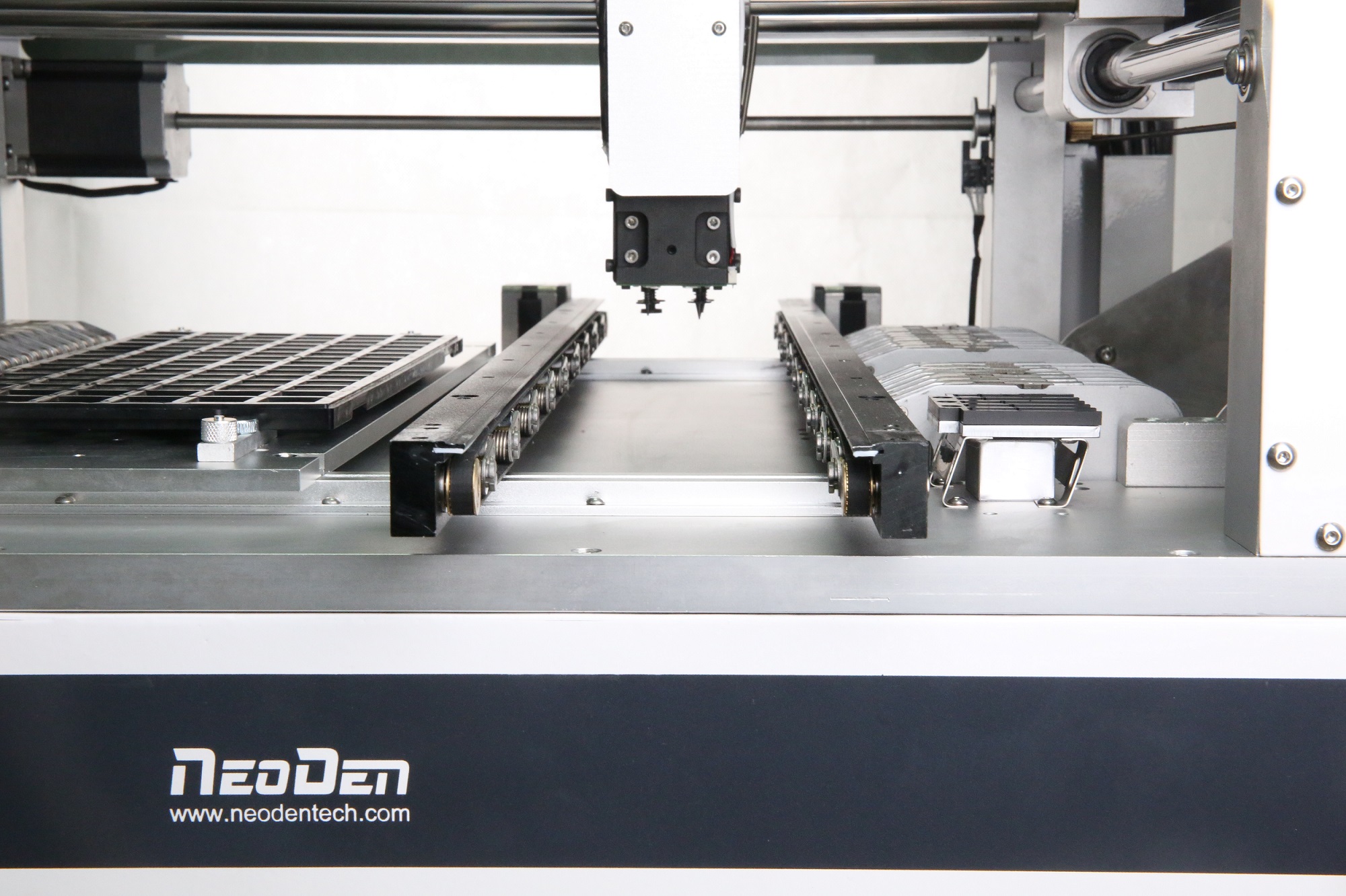

NeoDen4 SMT Pick and Place Machine Line

Specifications

| Product name | NeoDen4 SMT Pick and Place Machine Line |

| Machine Style | Single gantry with 4 Heads |

| Placement Rate | 4000CPH |

| External Dimension | L 680×W 870×H 460mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Details

On-line dual rails

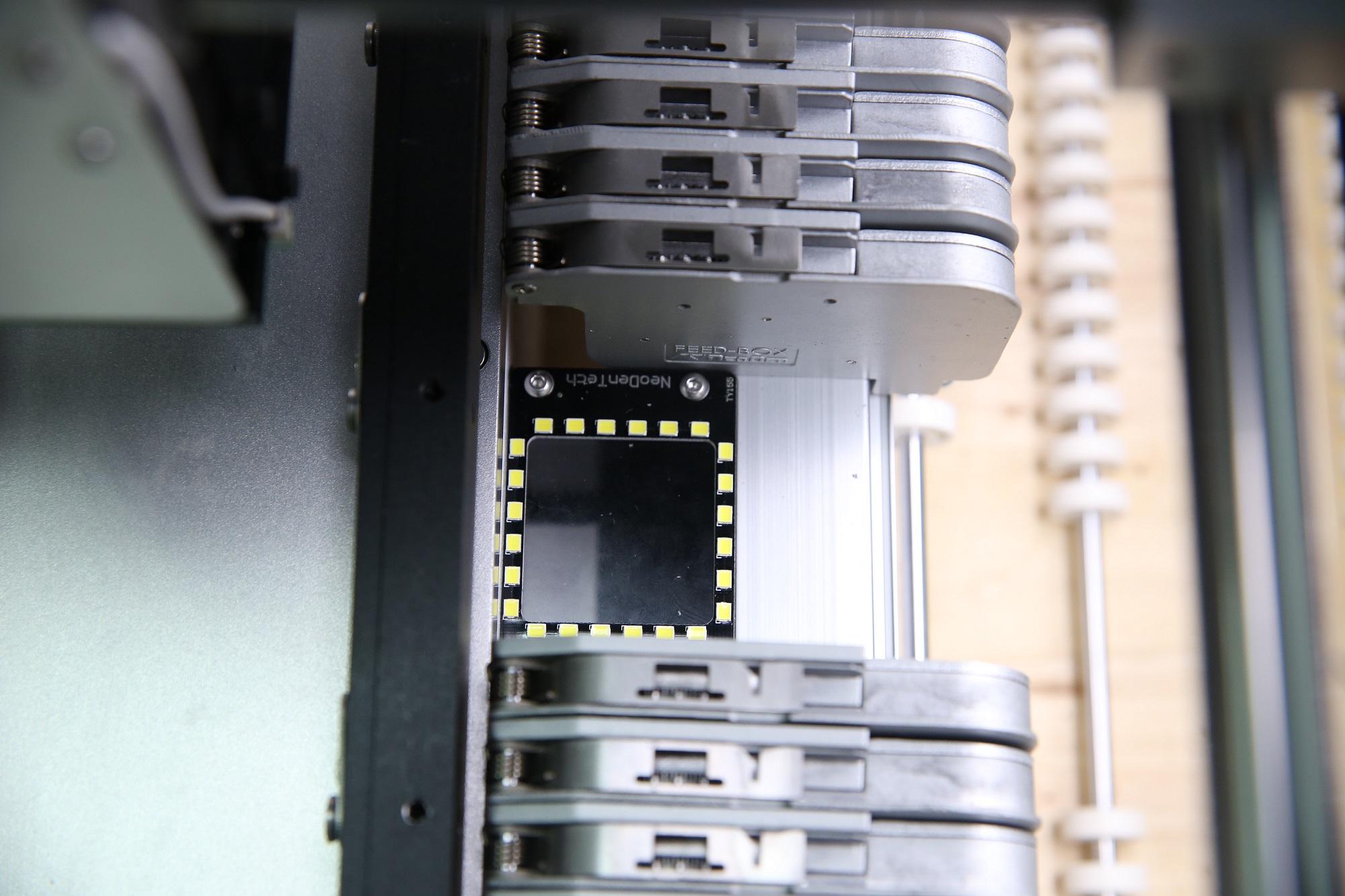

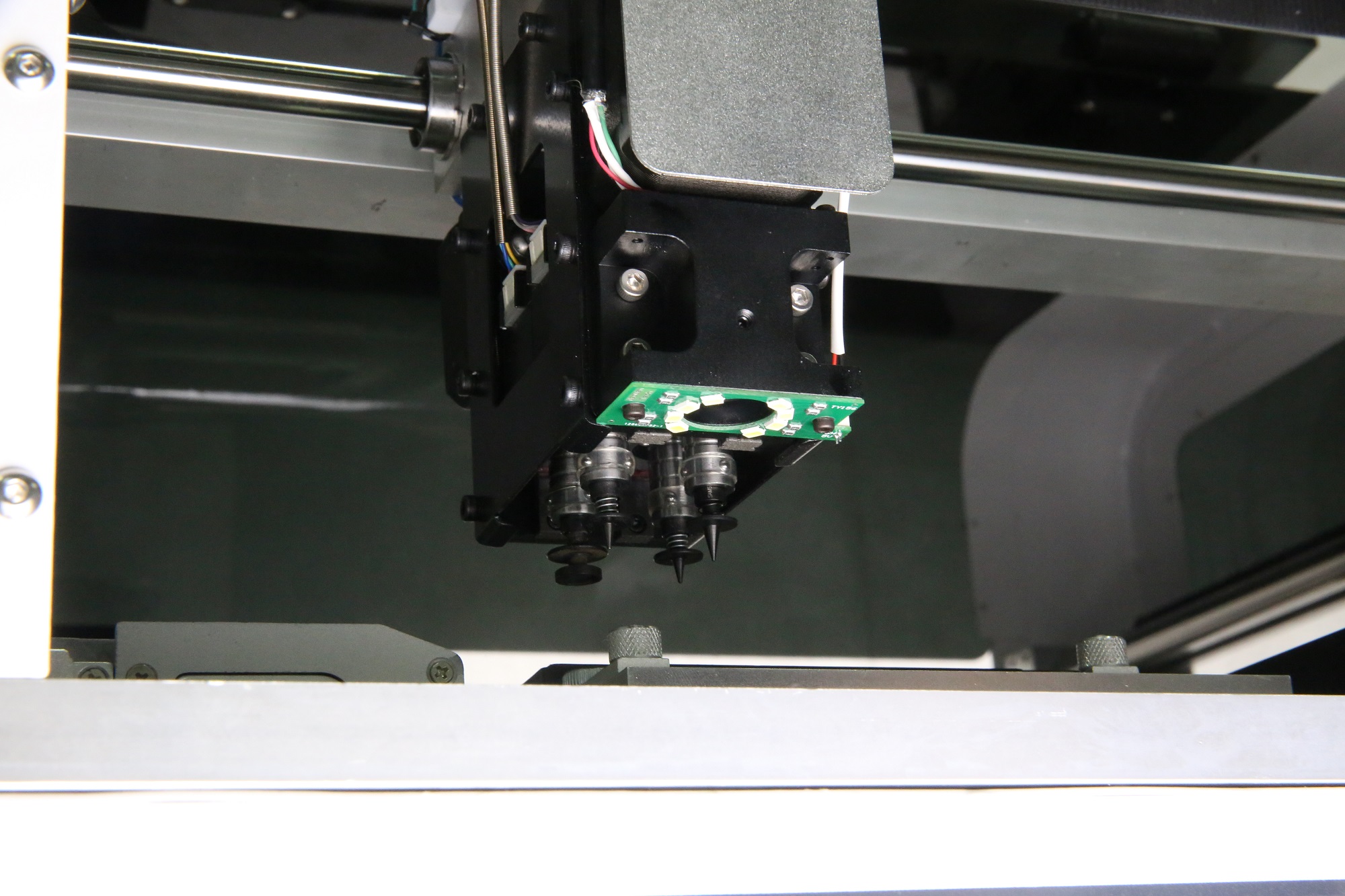

Vision system

Installed with high speed industry CCD cameras, and work with our patented image distortion processing algorithms, enable cameras can recognize and align different components of four nozzles. With the help of upper-camera and down looking camera, they will display the picking process with high definition image.

Four high precision nozzles

Electric tape-and-reel feeders

Packing

Caution

Provide one-stop SMT assembly production line

Related products

If you need, please feel free to contact us.

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate?

A: Yes. There are English manual and guide video that show you how to use machine.

If there is any doubt in the process of operating the machine, please feel free contact us.

We also provide overseas on-site service.

Q2: Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line and other SMT Products.

Q3: What we can do for you?

A: Total SMT Machines and Solution, professional Technical Support and Service.

About us

Exhibition

Certificates

Factory

If you need, please feel free to contact us.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.