SMT Reflow Soldering Station

SMT Reflow Soldering Station

Specification

1. Hot air convection, excellent soldering performance.

2. High-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature deviation is significantly reduced compare to the similar reflow oven products in the market.

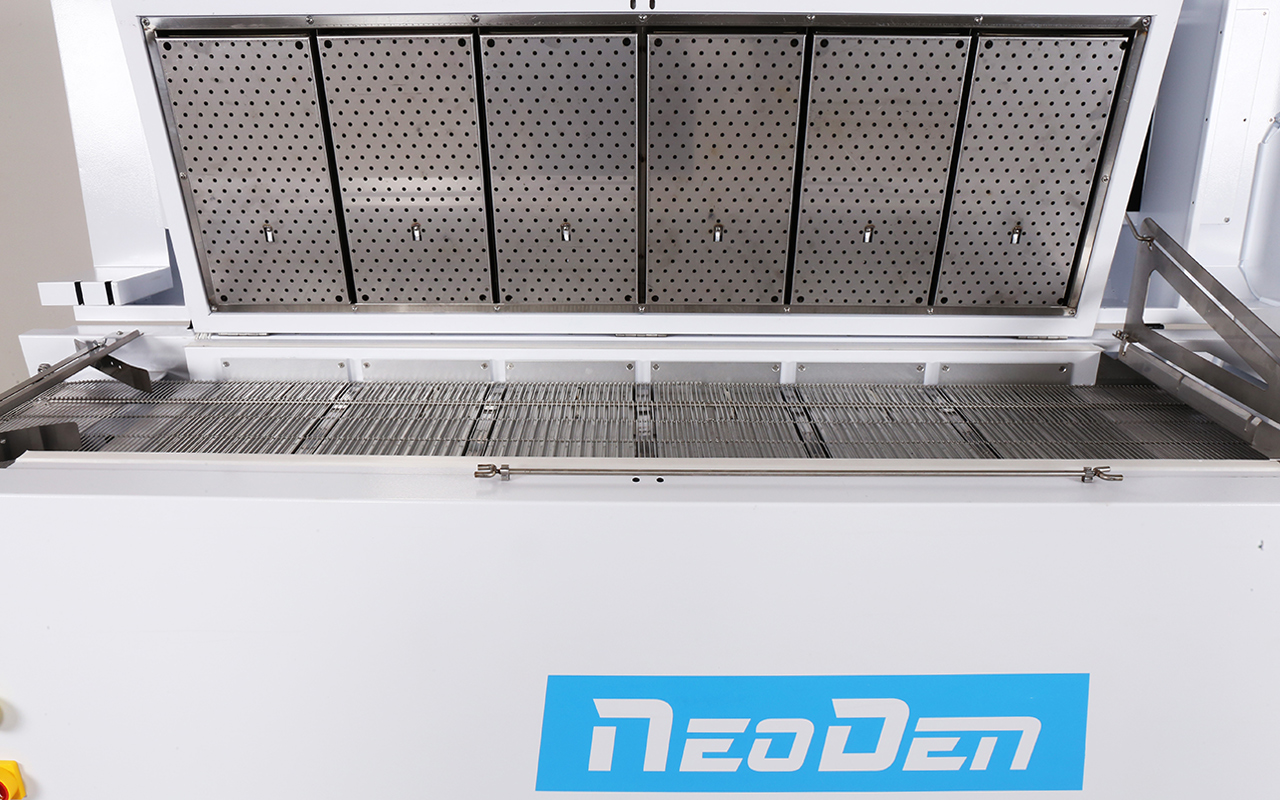

3. The custom-developed stainless steel B mesh belt is durable and wear-resistant. Not easy to deform after long time using.

4. The unique heating plate design effectively ensures IN12 will cool down evenly once the heating is stopped, and effectively prevents the deformation and damage caused by the rapid temperature drop

Feature

Product name: SMT Reflow Soldering Station

Cooling fan: Upper4

Conveyor speed: 50~600 mm/min

Temperature range: Room temperature~300℃

PCB temperature deviation: ±2℃

Max soldering height(mm): 35mm (includes PCB thickness)

Max soldering width (PCB Width): 350mm

Length process chamber: 1354mm

Electricity supply: AC 220v/single phase

Machine size: L2300mm×W650mm×H1280mm

Heat-up time: 30 min

Net weight: 300Kgs

Details

12 temperature zones

High temperature control accuracy

Uniform temperature distribution in the thermal compensation area

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power consumption, low power supply requirements

Operation panel

Hidden screen design

convenient for transportation

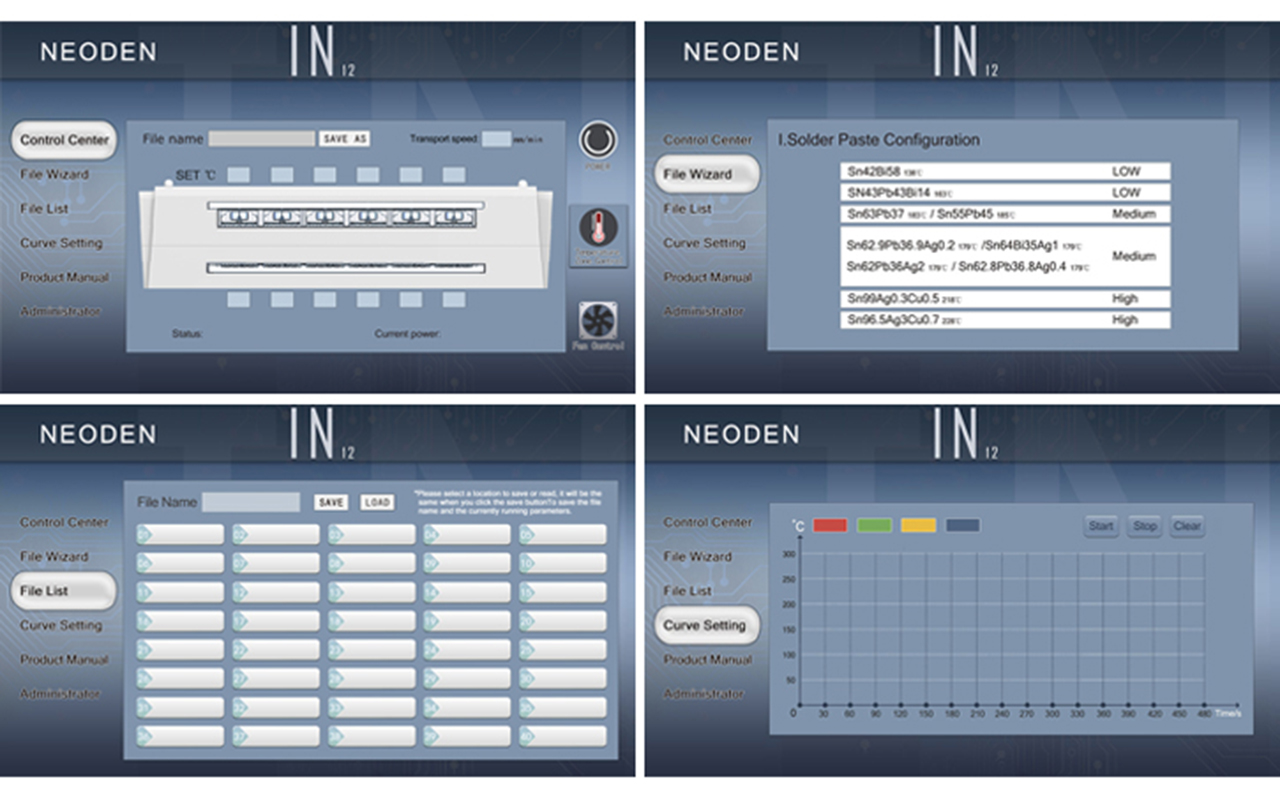

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

Chain Mesh Speed Setting

Click the speed parameter, a blank parameter dialog will pop out, type into the temperature you need set.

Generally suggestion 250-300mm/min

( Remarks: temperature will also be influenced once chain speed changed, please re-test the temperature curve and adjust temperature according to the test result )

Temperature setting

Data on upper side is well-set temperature from zone1 to zone6;

Data in the middle is the real-time temperature.

Click the temperature parameter dialog, directly type into the set temperature, the heating zone will start heating and keep it in a stable situation while temperature reached.

FAQ

Q1: How can I buy machine from you?

A: (1) Consult us on line or by e-mail.

(2) Negotiate and confirm the final price, shipping, payment method and other terms.

(3) Send you the perfroma invoice and confirm your order.

(4) Make the payment according to the method put on proforma nvoice.

(5) We prepare your order in terms of the proforma invoice after confirming your full payment. And 100% quality check before shipping.

(6) Send your order via express or by air or by sea.

Q2: What is your main market?

A: All over the world.

Q3: Is there the products tested before shipping?

A: Yes, of course.

All of our conveyor belt we all will has been 100% QC before shipping. We test every batch every day.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

Established in 2010, 200+ employees, 8000+ Sq.m. factory.

NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040.

40+ global partners covered in Asia, Europe, America, Oceania and Africa, to successfully serve 10000+ users in all of the world, to ensure the better and faster local service and prompt response.

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.