Manual Solder Printer – Semi-automatic solder paste printer YS350 – Neoden

Manual Solder Printer – Semi-automatic solder paste printer YS350 – Neoden Detail:

YS350Semi-automatic solder paste printer

|

ITEMS |

SPECIFICATION |

|

PCB size |

Max:400*240mm |

|

Printing area |

500*320mm |

|

PCB fixed system |

Pin positioning |

|

Frame size |

L(550-650)*W(370-470) |

|

Adjusting for table |

front/rear±10mm,left/right±10mm |

|

Printing Accuracy |

±0.2mm |

|

Repeating Accuracy |

±0.2mm |

|

PCB thickness |

0.2-2.0mm |

|

Air source |

4-6kg/c㎡ |

|

Power supply |

AC220V 50HZ/110V 60HZ |

|

Dimension |

L800*W700*H1700 |

|

Packing size |

1050*900*1850 |

|

Net weight |

230kg |

|

Gross weight |

280KG |

Features:

PC control ,touch screen display and menu operation interface

Floating scraper.similar to automatic printer, the scraper can be floated freely up and down and can be adjusted automatically to level with the steel grid.

The pressure of the scraper is adjustable .The pressure of the scraper on the steel grid is adjustable according to the length of the scraper.

The process of the stell gird removing from the PCB can be adjustable from 0 to 5seconds

Use both of your hands to press the button to operate so that the safety and reliability are ensured.

The stopping time of the scraper at top left or bottom left, and top right of bottom right,as well as the overall stopping time of the steel gird at top or bottom can be independently set in the touch screen menu.

The PCB can be localized and fastened by base hole , base side ,both base hole and base side ,and template localization.

Time can be displayed on the touch screen and the count of the printing time can be recorded .

The scraper speed at left and right is adjustable and can be stopped in emergency.

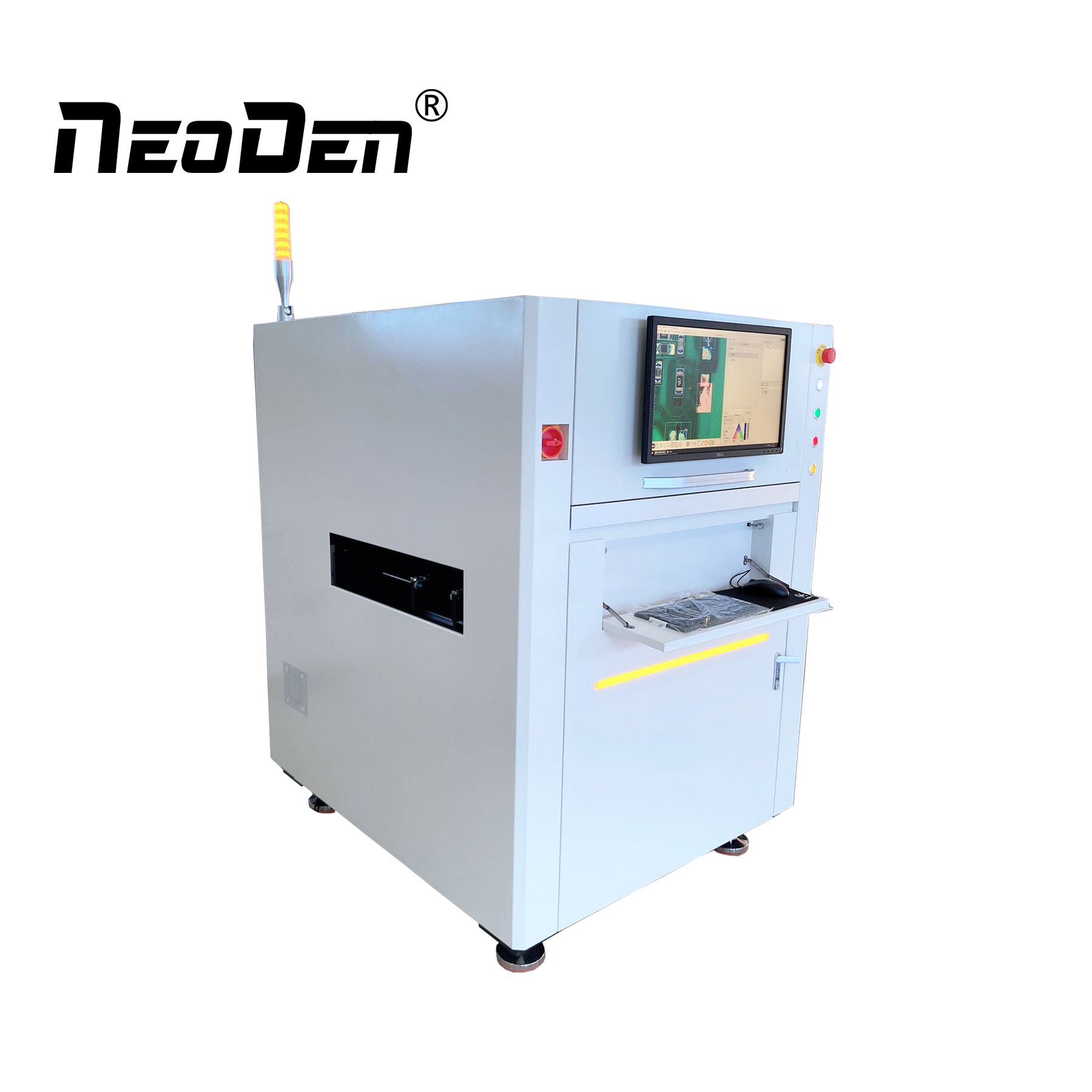

YS600Semi-automatic solder paste printer

|

ITEMS |

SPECIFICATION |

|

PCB size |

Max:600*240mm |

|

Printing area |

700*320mm |

|

PCB fixed system |

Pin positioning |

|

Frame size |

L(370-750)*W(470-850) |

|

Adjusting for table |

front/rear±10mm,left/right±10mm |

|

Printing Accuracy |

±0.2mm |

|

Repeating Accuracy |

±0.2mm |

|

PCB thickness |

0.2-2.0mm |

|

Air source |

4-6kg/c㎡ |

|

Power supply |

AC220V 50HZ/110V 60HZ |

|

Dimension |

L900*W700*H1700 |

|

Packing size |

1350*900*1850mm |

|

Net weight |

265kg |

|

Gross weight |

310kg |

Features:

PC control ,touch screen display and menu operation interface

Floating scraper.similar to automatic printer, the scraper can be floated freely up and down and can be adjusted automatically to level with the steel grid.

The pressure of the scraper is adjustable .The pressure of the scraper on the steel grid is adjustable according to the length of the scraper.

The process of the stell gird removing from the PCB can be adjustable from 0 to 5seconds

Use both of your hands to press the button to operate so that the safety and reliability are ensured.

The stopping time of the scraper at top left or bottom left, and top right of bottom right,as well as the overall stopping time of the steel gird at top or bottom can be independently set in the touch screen menu.

The PCB can be localized and fastened by base hole , base side ,both base hole and base side ,and template localization.

Time can be displayed on the touch screen and the count of the printing time can be recorded .

The scraper speed at left and right is adjustable and can be stopped in emergency.

YS1200Semi-automatic solder paste printer

|

ITEMS |

SPECIFICATION |

|

PCB size |

Max:1200*240mm |

|

Printing area |

1300*320mm |

|

PCB fixed system |

Pin positioning |

|

Frame size |

L(1550-1650)*W(370-470) |

|

Adjusting for table |

front/rear±10mm,left/right±10mm |

|

Printing Accuracy |

±0.2mm |

|

Repeating Accuracy |

±0.2mm |

|

PCB thickness |

0.2-2.0mm |

|

Air source |

4-6kg/c㎡ |

|

Power supply |

AC220V 50HZ/110V 60HZ |

|

Dimension |

L1600*W700*H1700 |

|

Packing size |

1900*900*1850mm |

|

Net weight |

300kg |

|

Gross weight |

350KG |

Features:

PC control ,touch screen display and menu operation interface

Floating scraper.similar to automatic printer, the scraper can be floated freely up and down and can be adjusted automatically to level with the steel grid.

The pressure of the scraper is adjustable .The pressure of the scraper on the steel grid is adjustable according to the length of the scraper.

The process of the stell gird removing from the PCB can be adjustable from 0 to 5seconds

Use both of your hands to press the button to operate so that the safety and reliability are ensured.

The stopping time of the scraper at top left or bottom left, and top right of bottom right,as well as the overall stopping time of the steel gird at top or bottom can be independently set in the touch screen menu.

The PCB can be localized and fastened by base hole , base side ,both base hole and base side ,and template localization.

Time can be displayed on the touch screen and the count of the printing time can be recorded .

The scraper speed at left and right is adjustable and can be stopped in emergency.

Packing

Export Packing ——— Vacuum Packing and Plywood Box

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

It really is our obligation to satisfy your requirements and efficiently serve you. Your fulfillment is our greatest reward. We're hunting forward to your check out for joint development for Manual Solder Printer – Semi-automatic solder paste printer YS350 – Neoden , The product will supply to all over the world, such as: Denmark, French, Ireland, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!