NeoDen ND1 Full Automatic Visual Printer Solder Paste Printer

NeoDen ND1 Full Automatic Visual Printer Solder Paste Printer

Specification of Solder Past Printer

| Product name | NeoDen ND1 Full Automatic Visual Printer Solder Paste Printer |

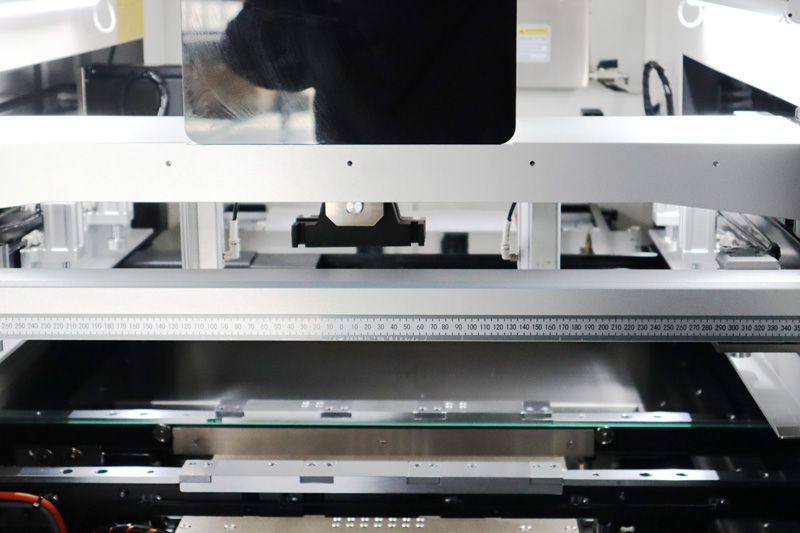

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.6mm~14mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 10Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R, R-L, L-L, R-R |

| Machine weight | Appro.1000Kg |

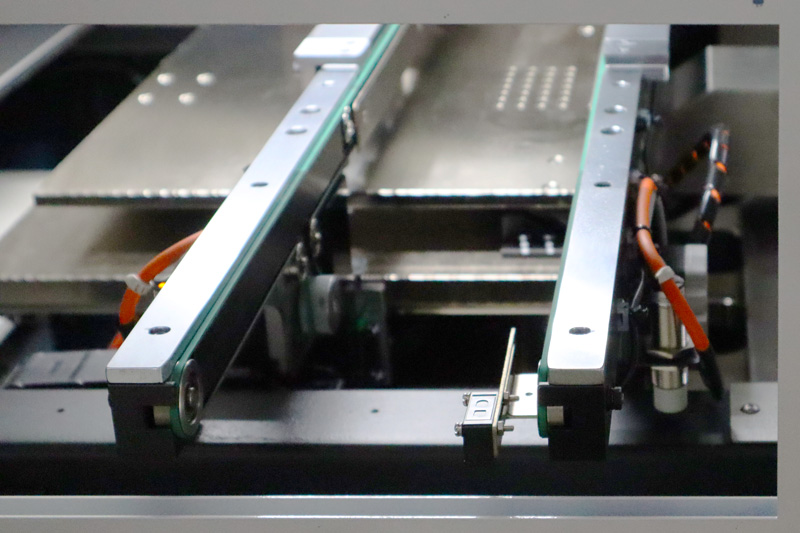

Features of Stencil Printer SMT

PCB clamp mode: Software adjustable pressure of the elastic side pressure.

Option

1. Overall bottom suction chamber vacuum

2. Bottom multipoint partial vacuum

3. Edge lock clamping plate

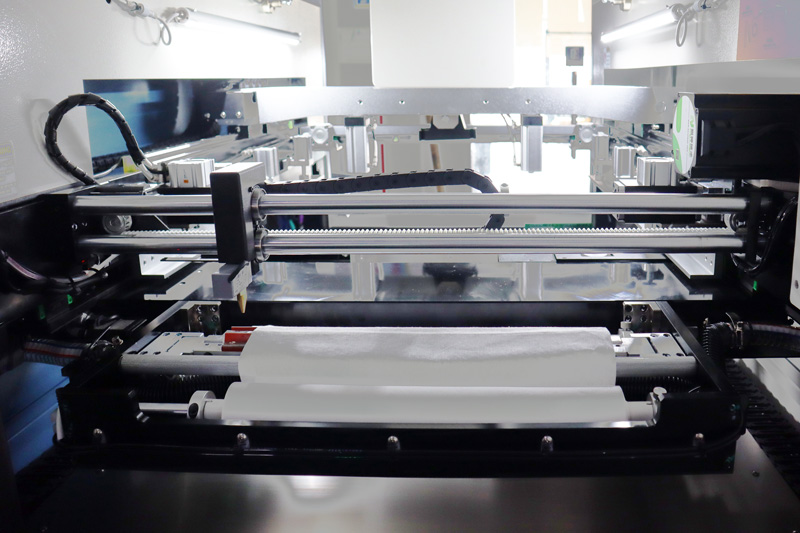

Board support method Magnetic thimble, special work holding device. (option: Grid-Lok)

Image parameter

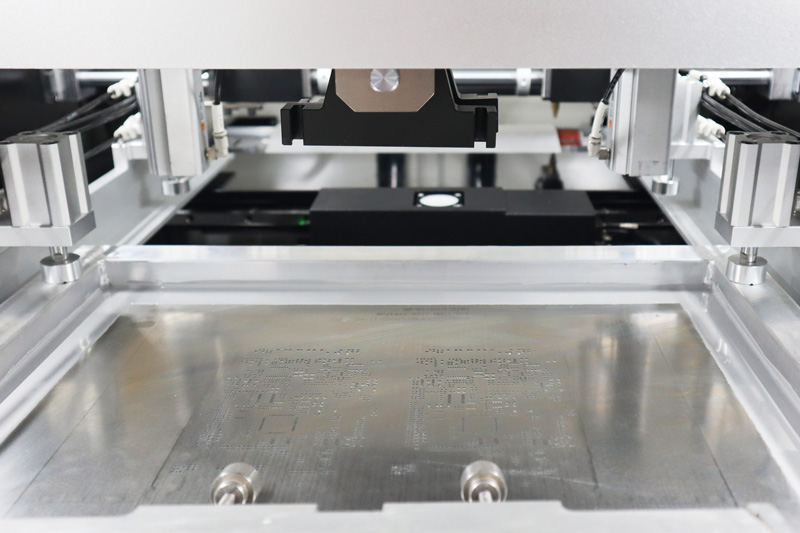

Image view (FOV): 6.4mm x 4.8mm

Platform adjustment range: X, Y: ±7.0mm, θ: ± 2.0 º

Base point type Standard shape reference point (SMEMA standard), solder paste /open hole.

Camera system individual camera, up or down individual imaging vision system, geometrical matching positioning.

SMT Stencil Printing Detail

Specification

Accurate Printing of Solder Paste

Fully automated solder paste printers are able to accurately control the amount and position of the solder paste to ensure uniform application on each pad, improving printing accuracy that is difficult to achieve by manual operation.

Reduced Human Error

Due to the automated control of PCB solder paste printers, errors due to manual operation are significantly reduced, resulting in increased consistency and reliability in the production process.

Reduced solder paste waste

Solder paster printers can accurately control the amount of solder paste used, reducing the amount of solder paste wasted during operation and thus reducing production costs.

Ensure print quality

SMD solder paste printer is usually equipped with various online inspection systems that can monitor the print quality in real time to ensure that every print is up to standard, thus improving the yield rate of the entire SMT production line.

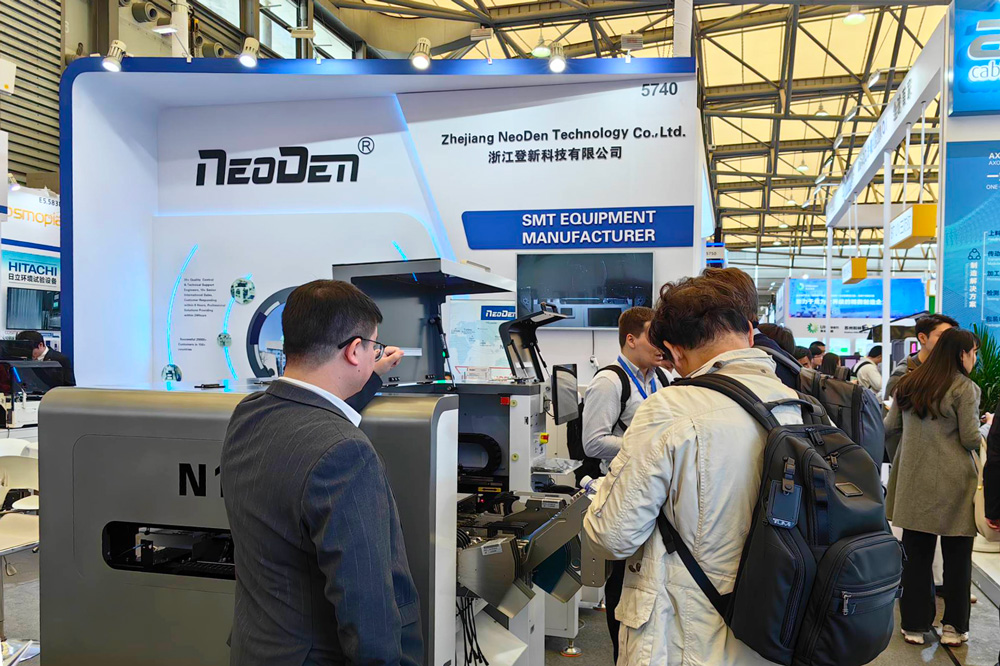

About us

Factory

Certification

Exhibition

FAQ

Q1. What is the difference between ND1 and ND2?

A. The PCB thickness adjustment method is different.ND2 could automatically adjust PCB thickness but ND1 need to be adjusted manually.

The squeegee structure of ND2 is driven by ball screw and servo motor, the ND1 is belt driven and stepper motor.

Q2. What's the PCB clamping method?

A. Software adjustable flexible side clamps

Q3. What is the printing accuracy

A. Repeatibility:±25μm, mainly used to print 0402, 0603 and minium 0201.

Q4. What are the options?

- Automatically solder paste filling function

- Detection function of Solder Paste margin of stencil

- Detection of Stencil plugging

- Magnetic Squeegee

- Automatic temperature and humidity inspection

- MES system seamless docking

- Squeegee pressure closed loop control feedback system

- Automatic dispensing function

- PCB Positioning Vacuum Cavity and Upper Press Function

Q5. Is it easy to operate?

A. Yes, the printer is easy to master, and we could provide user manual and onlin training for you.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.