News

-

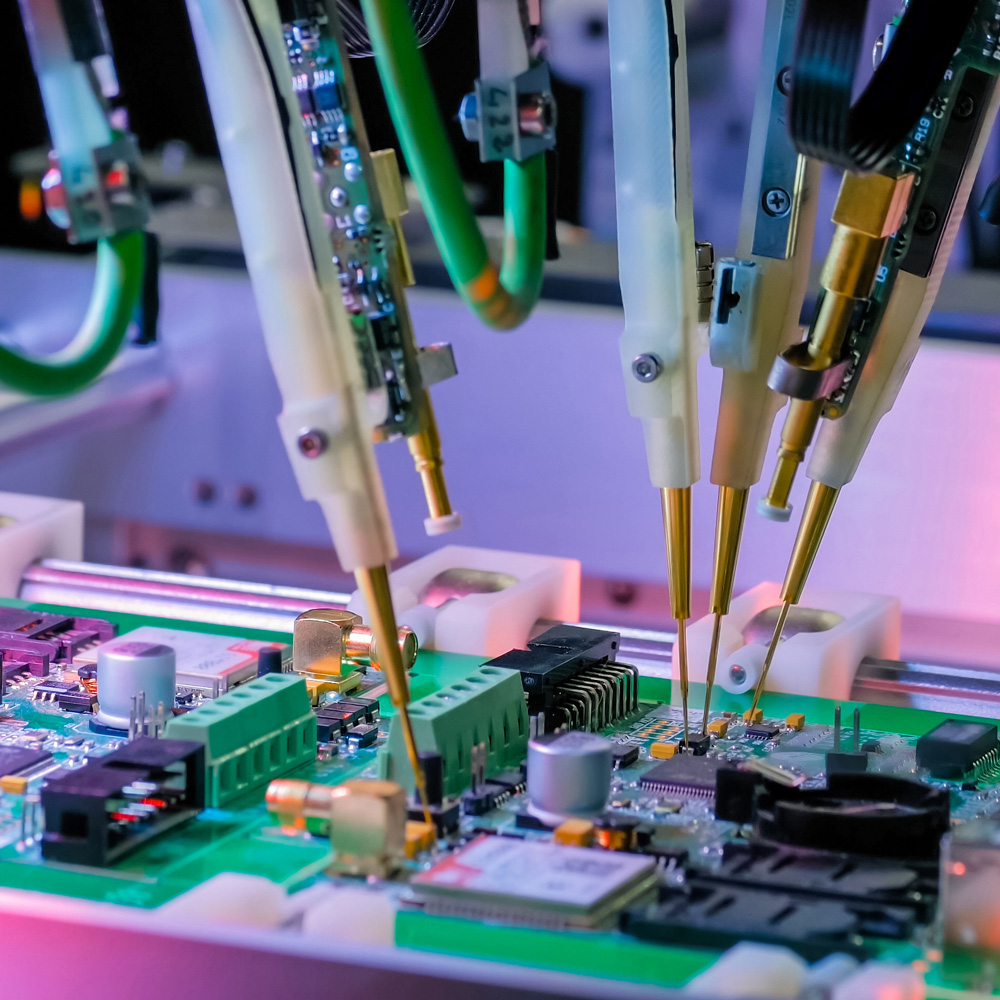

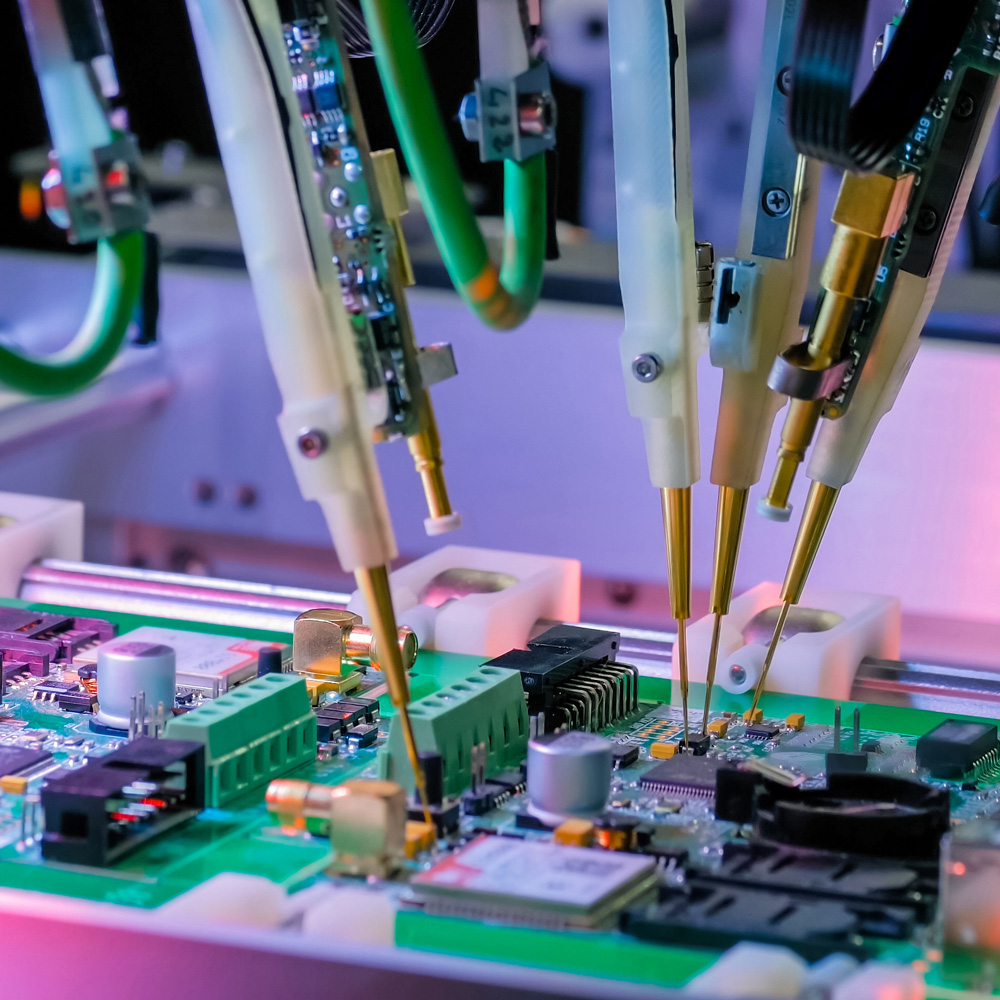

NeoDen YY1 Show At Australia Electronics Event Electronex

Company name: Embedded Logic Solutions Pty Ltd Address: Melbourne Exhibition Centre Time: Wed 10 – Thur 11 May 2023 Booth number: Stand D2 Embedded Logic Solutions Pty Ltd takes the popular desktop pick& place machine YY1 at Australia’s Largest Electronics Event Electronex...Read more -

NeoDen YY1 at Automation ExpoSouth Exhibition

Automation ExpoSouth, 26th -28th Apr. 2023 NeoDen India – CHIPMAX DESIGNS PVT LTD takes the popular desktop pick& place machine YY1 at Automation ExpoSouth exhibition, welcome to visit us at Stall #E-18. Quick facts about NeoDen ① Established in 2010, 200+ employees, 8000+ Sq.m. factor...Read more -

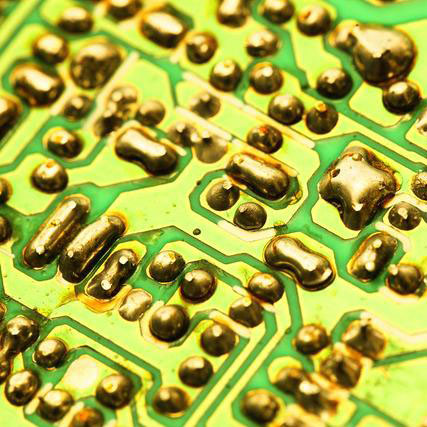

What features to consider when choosing a gold plating method for PCBs?

There are several characteristics that determine your choice of plating method. Here are four important aspects that you need to consider: Solderability As flash gold PCBs include some non-precious metal elements, this makes it more difficult to make them solderable. ENIG is therefore a better ch...Read more -

How to choose the right surface finish for your PCB?

Here are some expert tips on how to make this decision: 1. Affordability In terms of a comparison between HASL lead-free and HASL leaded, we would say that the former is more costly. Therefore, if you are on a tight budget or want to save money, going for a HASL lead finish is a better way to sav...Read more -

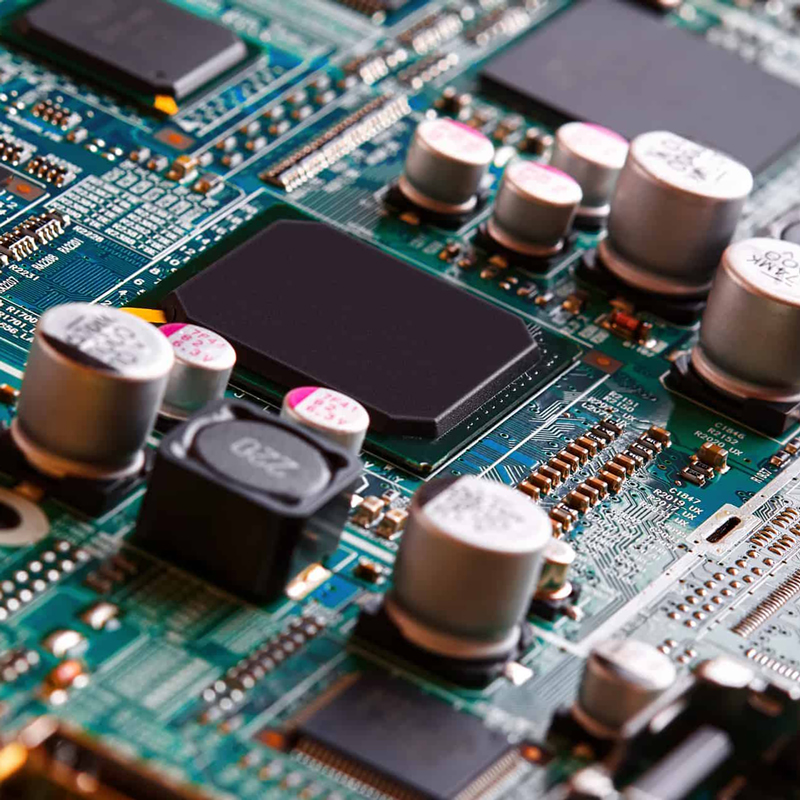

The Importance of PCBA Component Layout

SMT chip processing gradually to high density, fine pitch design development, the minimum spacing of components design, need to consider the SMT manufacturer’s experience and process perfection. The design of the minimum spacing of components, in addition to ensuring the safety distance bet...Read more -

How to choose the right SMD LED PCB?

Choosing the right SMD LED PCB for your project is an important step in designing a successful LED-based system. There are several factors to consider when selecting an SMD LED PCB. These factors include the size, shape and colour of the LEDs as well as the voltage and current requirements of the...Read more -

How Presensitized PCBs Are Different from Traditional PCB?

The following reasons are enough to tell you how Photoresist PCBs are different from regular PCBs. 1. Great in demand Presensitized PCBs are in great demand due to their ease of use and easy availability. In simple words, these are ready-made PCBs, and that’s why people like to use these PCBs. As...Read more -

NeoDen YY1 Showed at Nepcon Korea 2023 Exhibition

NeoDen official Korean distributor—- 3H CORPORATION LTD. took the SMT prototype desktop pick& place machine YY1 at the exhibition, welcome to visit booth H113 . YY1 is featured with automatic nozzle changer, support short tapes, bulk capacitors and support max. 12mm height components. S...Read more -

Steps for Making of Induction PCBs

1. Choosing the Right Materials Selecting the right materials is essential for creating high-quality induction PCBs. The choice of materials will depend on the specific requirements of the circuit and the operating frequency range. For example, FR-4 is a common material used for lower frequency P...Read more -

NeoDen SMT machine show at AUTOMATION. ELECTRONICS 2023

NeoDen SMT machine show at AUTOMATION. ELECTRONICS-2023 4th- 7th, Apr.2023 Place: Minsk, Belarus Booth: D7/C23 NeoDen official local distributor in Belarus —- ELETECH will take the NeoDen9 pick and place machine, NeoDenIN6 reflow oven there and we sincerely welcome customers visit our b...Read more -

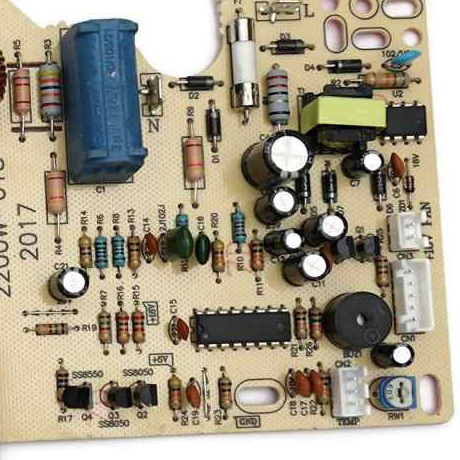

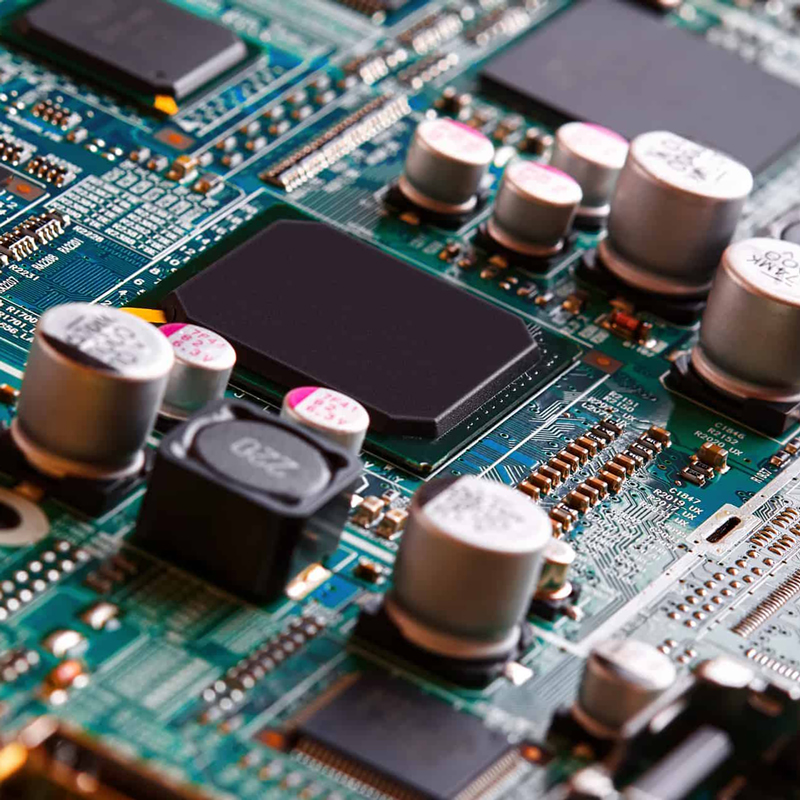

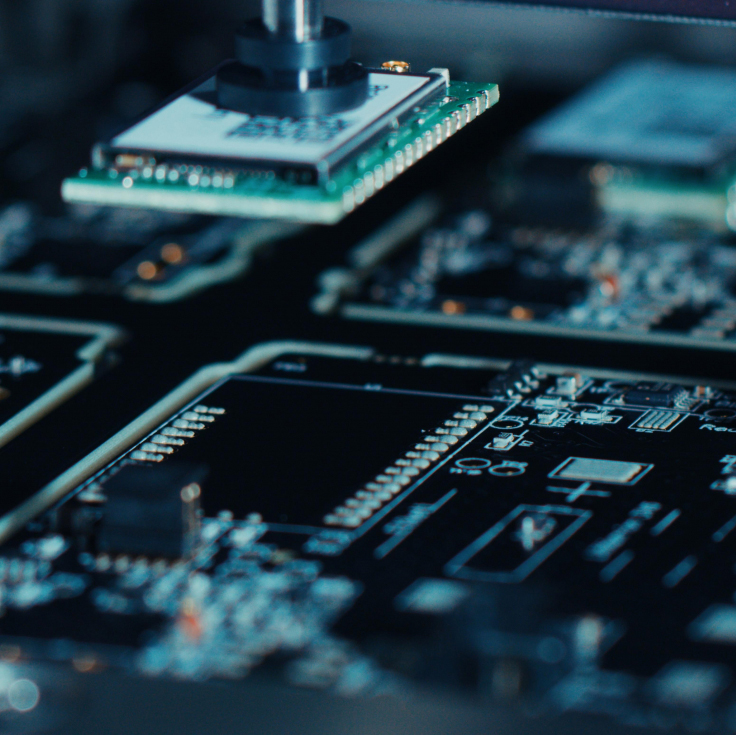

The Categories of Industrial Circuit Boards

Industrial PCBs by rigidity These refer to printed circuit boards (PCBs) designed to meet the different needs of industrial equipment components, based on the degree of rigidity of the board. Flexible industrial PCBs As the name suggests, these industrial circuit boards are flexible, i.e. ...Read more -

The Methods of Panelizing PCBs

There are different methods for making panelized PCBs, and each is unique. Although the PCB breakaway design and V-scoring are the most outstanding, there are a couple of others. Here is a breakdown of how each of the circuit board panelization methods work: 1. Tab Routing Also called the PCB bre...Read more