IV. Lead pull method

This method is suitable for disassembly of chip – mounted integrated circuits. Use an enameled wire of appropriate thickness, with certain strength, through the inner gap of the integrated circuit pin. One end of the enameled wire is fixed in place and the other end is held by hand. When the solder on the pin of an integrated circuit melts. Pull the enameled wire to “cut” the solder joint and the IC pins are separated from the PCB.

V. Air gun soldering iron matching method

Adjust the temperature of the air gun to the maximum of more than 500 degrees, moderate air volume, continuous heating of two strips of tin, solder is completely dissolved after more than ten seconds, easy to remove with pointed tweezers, but this method is easy to affect the surrounding circuit, careful operation. Next is according to the new device, first with rosin water besmear is on solder wire, or use the rosin powder scattered on the bonding pad, with a clean welding steel-toed heating weld plate of lead, the lead wet light, lead tin is not completely clear, when welding head heating wire, try to move toward the periphery, make the residual lead tin on welding plate peripheral. Use a small tool to clean up the rosin debris on the pad lead. Take a piece of new IC, with the help of rosin to tin on IC pin, the pin wet light without burr, the IC is on the desktop, press with finger, make IC pin up a little cock, put the IC are welding plate, with pointed tweezers pin IC middle position, eyes not good comrades can use a magnifying glass to watch, After placing the pointed welding iron can be used to heat the tin on the periphery of the pad, the soldering iron head pushes the IC pin inward after the tin melts, so that the pin forms a right Angle on the pad. It is necessary to weld the four diagonal angles first, take a rest after welding, and then weld the other feet. After all the welding, the magnifying glass can be used to observe, and a small amount of tin can be used in bad places.

VI. Removal method of tin absorber

There are two kinds of soldering iron and tin absorber. When the ordinary tin absorber is used, the piston rod of the tin absorber is pressed down. When the solder joint of the electric soldering iron is melted, the suction mouth of the tin absorber is close to the melting point, and the release button of the tin absorber is pressed. The piston rod of the tin absorber will spring back and suck the molten tin away. Repeated several times, can be removed from the printed board.

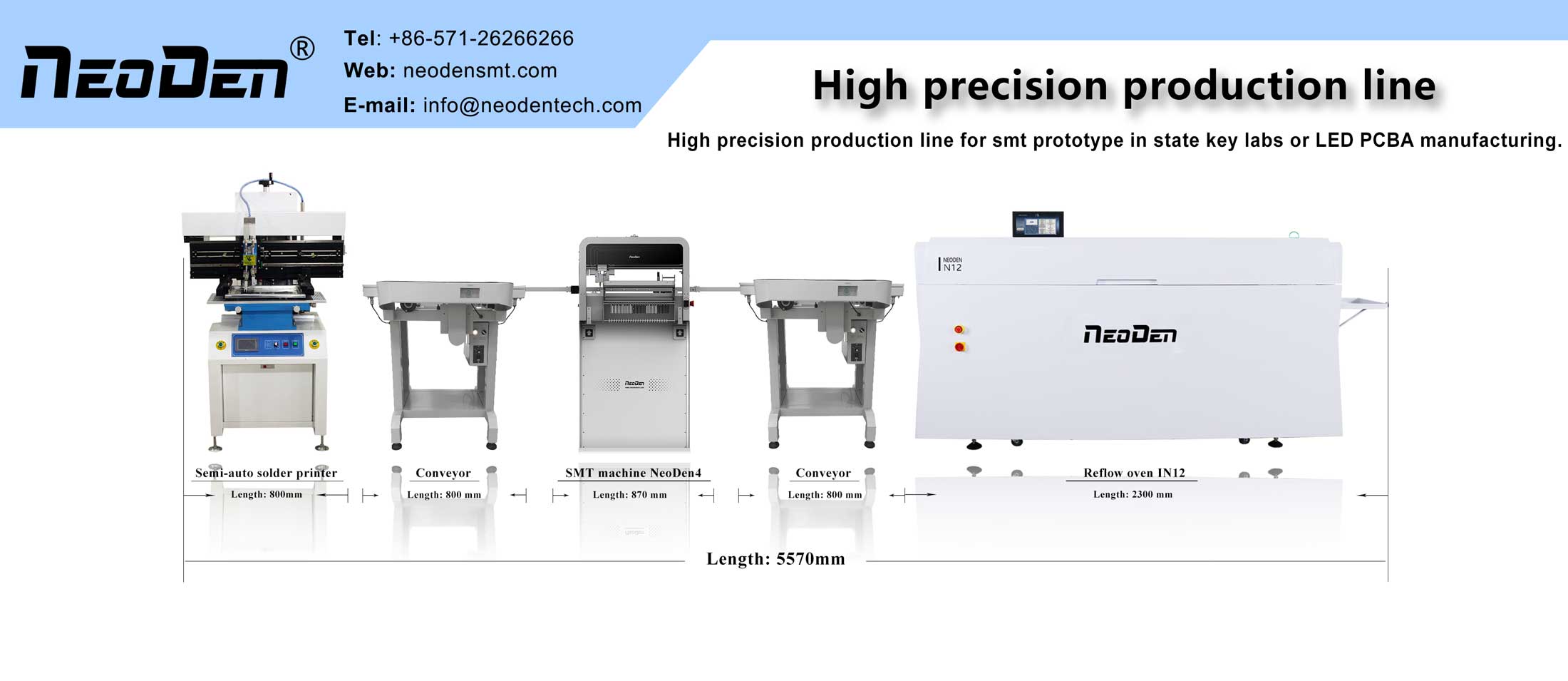

NeoDen provides a full SMT assembly line solutions, including SMT reflow oven, wave soldering machine, pick and place machine, solder paste printer, Reflow oven, PCB loader, PCB unloader, chip mounter, SMT AOI machine, SMT SPI machine, SMT X-Ray machine, SMT assembly line equipment, PCB production Equipment SMT spare parts, etc any kind SMT machines you may need, please contact us for more information:

Zhejiang NeoDen Technology Co., Ltd

Web: www.smtneoden.com

Email: info@neodentech.com

Post time: Jun-18-2021