NeoDen ND2 Automatic SMT Paste Printer PCB Solder Printer

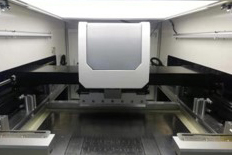

Automatic SMT paste printer PCB solder printer

Technical parameter

| I. PCB parameter | |||

| Maximum board size(X x Y) | 450mm x 350mm | Board margin gap | Configuration to 3mm |

| Minimum board size(X x Y) | 50mm x 50mm | Maximum bottom gap | 20mm |

| PCB thickness | 0.4mm~6mm | Transfer speed | 1500mm/s(Max) |

| Warpage | ≤1% Diagonal | Transfer height from the ground | 900±40mm |

| Maximum board weight | 3Kg | Transfer orbit direction | L-R, R-L, L-L, R-R |

| Machine weight | Appro.1000Kg | ||

| II. Printing parameters | |||

| Printing head | Floating intelligent printing head

(two independent direct connected motors) |

Template frame size | 470mm*370mm~737 mm*737 mm |

| Maximum printing area(X*Y) | 450mm*350mm | Squeegee height | 65±1mm |

| Squeegee type | Steel/Glue Squeegee

(Angel 45°/50°/60° matching the printing process) |

Squeegee length | 300mm/520mm

(optional with length of 200mm-550mm) |

| Squeegee thickness | 0.25mm Diamond-like carbon coating | Printing mode | Single or double Squeegee printing |

| Demoulding length | 0.02mm-12mm | Printing speed | 0~200mm/s |

| Printing pressure | 0.5kg-10Kg | Printing stroke | ±200mm (From the center) |

| III. Performance parameters | |||

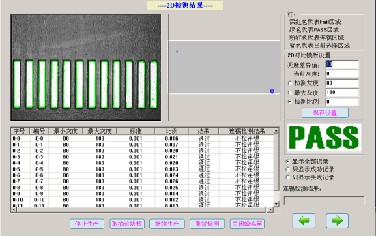

| Repeat position accuracy | ±10.0μm @6 σ,Cpk ≥ 2.0 | Repetition accuracy | ±20.0μm @6 σ,Cpk ≥ 2.0 |

| Cycle time | <7s (Exclude printing and cleaning) | Product changeover | <5min |

| Power requirements | AC220V±10%,50/60HZ,15A | Compressed air requirements | 4~6Kg/cm² |

| Operating system | Win7 | External dimension | 1152mm(L)*1415mm(W)*1540mm(H)

(Without light,monitor and keyboard) |

| Machine weight | Appro.1000Kg | ||

Technical parameter

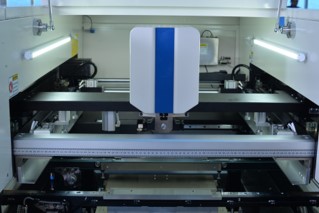

Accurate optical positioning system

Quality inspection and SPC analysis

Stencil cleaning system

Special PCB thickness adaptive system

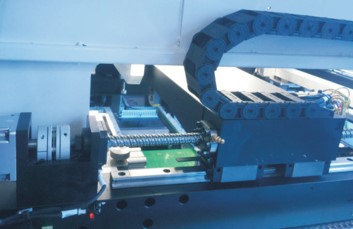

Printing axis servo drive

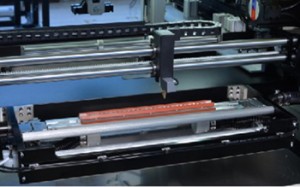

Intelligent squeegee system

Function

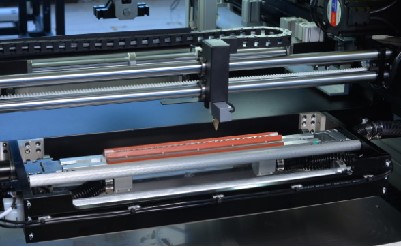

1. NeoDen ND2 solder paste printer equips with advanced up/down visual system, independent controllable and adjusted lighting, high speed mobile camera lens, precisely alignment for the PCB and template and make sure that the printing accuracy is ±0.025mm.

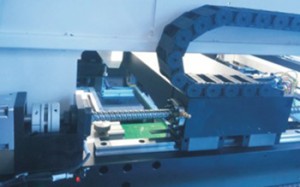

2. High accurate servo motor and PC control which can insure the stability and precision of the printing. Unlimited image pattern recognition technology has the repeated positioning accuracy for ±0.01mm.

3. Suspended printing head which is designed specially in high rigid structure. The computer controls the pressure, speed and movement of the scraper, which can maintain the even and stability of the printing. The structure of scraper beam has been optimized designed. The scraper beam is light and well-formed.

4. The bottom of the board can be cleaned by manual or automatically. The clean function for the bottom of board is automatic and without assists. It can be programmed to control the dry, wet or vacuum cleaning. The cleaning time interval can be free to choose. It can clean all the solder paste inside the boar holes and insure the printing quality.

5. There is composite worktable which can set a thimble and vacuum chamber (optional) according to the size of PCB baseboard. It makes the fixture assembling more fast and easy.

Related products

About Us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

Certification

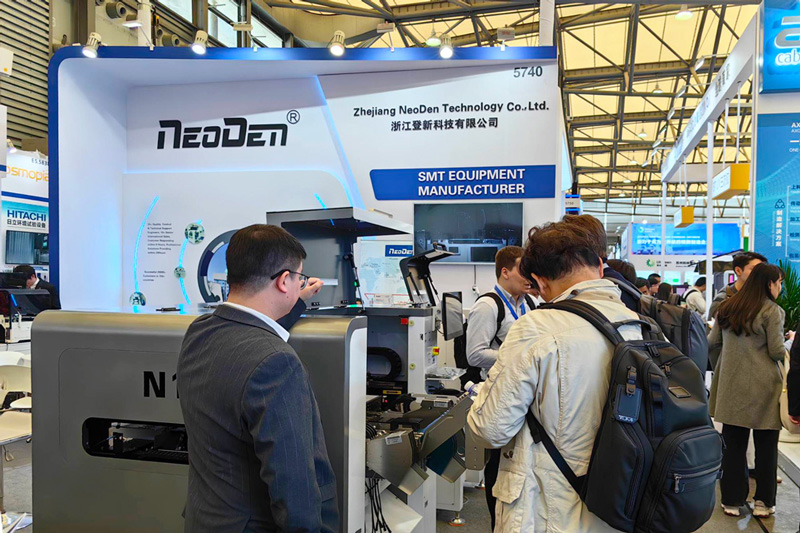

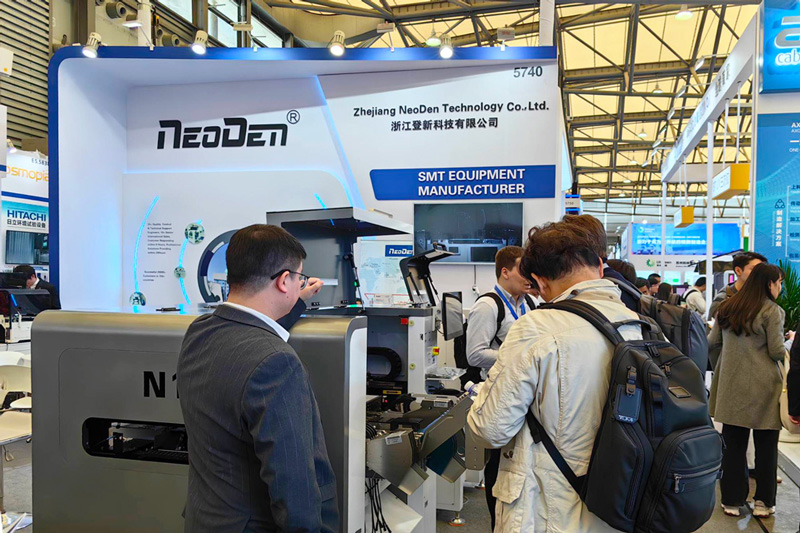

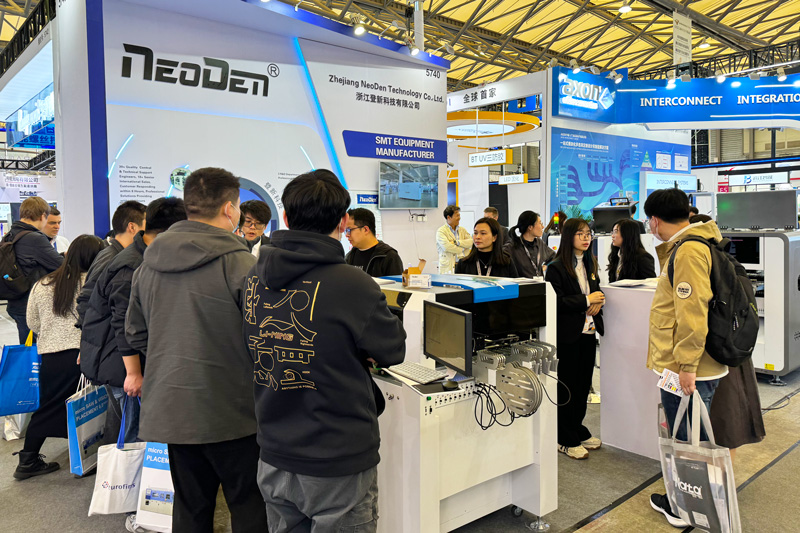

Exhibition

If you need, please feel free to contact us for more information.

FAQ

Q1. What is the difference between NeoDen ND1 and ND2 solder paste stencil printer?

The PCB thickness adjustment method is different.ND2 could automatically adjust PCB thickness but ND1 need to be adjusted manually.

The squeegee structure of ND2 is driven by ball screw and servo motor, the ND1 is belt driven and stepper motor.

Q2. What's the PCB clamping method?

Programmable flexible side clamps + removable clamping

Q3. What is the printing accuracy?

Repeatibility:±20μm,mainly used to print 0201,0402 and minium 01005.

Q4. What are the options?

- Automatically solder paste filling function

- Detection function of Solder Paste margin of stencil

- Detection of Stencil plugging

- Magnetic Squeegee

- Automatic temperature and humidity inspection

- MES system seamless docking

- Squeegee pressure closed loop control feedback system

- Automatic dispensing function

- PCB Positioning Vacuum Cavity and Upper Press Function

Q5. Is it easy to operate?

Yes, the printer is easy to master, and we could provide user manual and onlin training for you.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.