Company news

-

Company profile

Hangzhou NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We have our own R & D team and own factory, taking advantage of our own rich expe...Read more -

Types of reflow oven II

Classification according to shape 1. Table reflow welding furnace Desktop equipment is suitable for small and medium batch PCB assembly and production, stable performance, economical price (about 40,000-80,000 RMB), domestic private enterprises and some state-owned units used more. 2. Vertical re...Read more -

Types of reflow oven I

Classification according to technology 1. Hot air reflow oven Reflow oven is carried out in this way by using heaters and fans to heat up the internal temperature continuously and then circulate. This type of reflow welding is characterized by laminar flow of hot air to transfer the heat required...Read more -

110 knowledge points of SMT chip processing – Part 1

110 knowledge points of SMT chip processing – Part 1 1. Generally speaking, the temperature of SMT chip processing workshop is 25 ± 3 ℃; 2. Materials and things needed for solder paste printing, such as solder paste, steel plate, scraper, wiping paper, dust-free paper, detergent and mixing ...Read more -

Some common problems and solutions in soldering

Foaming on PCB substrate after SMA soldering The main reason for the appearance of nail size blisters after SMA welding is also the moisture entrained in the PCB substrate, especially in the processing of multilayer boards. Because the multilayer board is made of multi-layer epoxy resin prepreg a...Read more -

The factors affecting the quality of reflow soldering

The factors affecting the quality of reflow soldering are as follows 1. Influencing factors of solder paste The quality of reflow soldering is affected by many factors. The most important factor is the temperature curve of reflow furnace and the composition parameters of solder paste. Now the c...Read more -

Selective Soldering Oven Inside System

1. Flux spraying system Selective wave soldering adopts a selective flux spraying system, that is, after the flux nozzle runs to the designated position according to the programmed instructions, only the area on the circuit board that needs to be soldered is sprayed wit...Read more -

Reflow soldering principle

The reflow oven is used to solder the SMT chip components to the circuit board in the SMT process soldering production equipment. The reflow oven relies on the hot air flow in the furnace to brush the solder paste on the solder joints of the solder paste circuit b...Read more -

WAVE SOLDERING DEFECTS

Incomplete Joints on a Printed Circuit Board-WAVE SOLDERING DEFECTS The incomplete solder fillet is often seen on single-sided boards after wave soldering. In Figure 1, the lead-to-hole ratio is excessive, which has made soldering difficult. There is also evidence of resin smear on the edg...Read more -

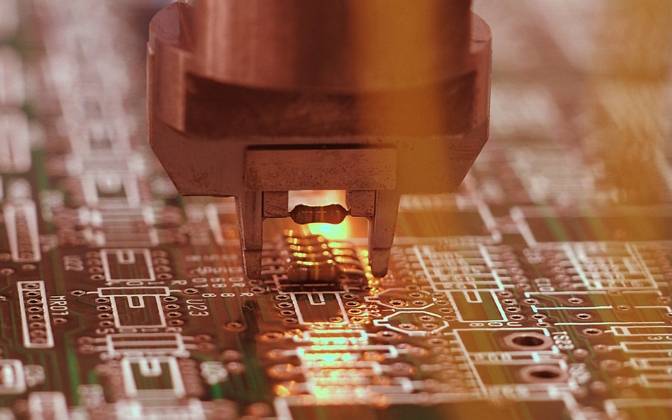

SMT basic knowledge

SMT basic knowledge 1. Surface Mount Technology-SMT (Surface Mount Technology) What is SMT: Generally refers to the use of automatic assembly equipment to directly attach and solder chip-type and miniaturized leadless or short-lead surface assembly components/devices (...Read more -

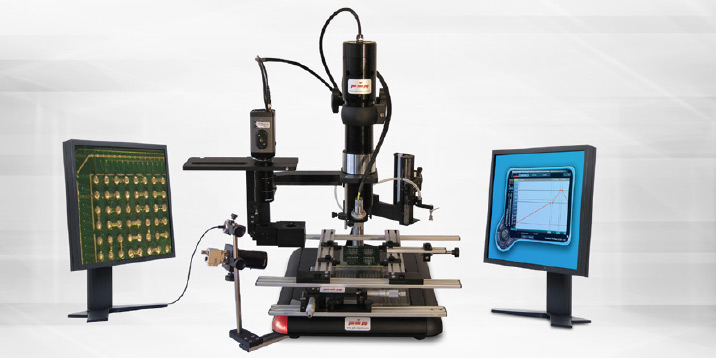

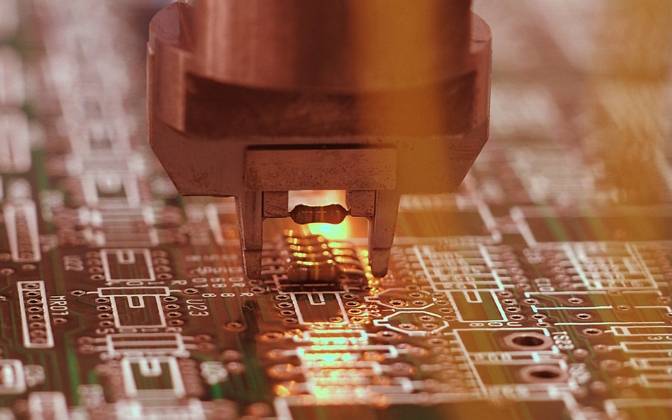

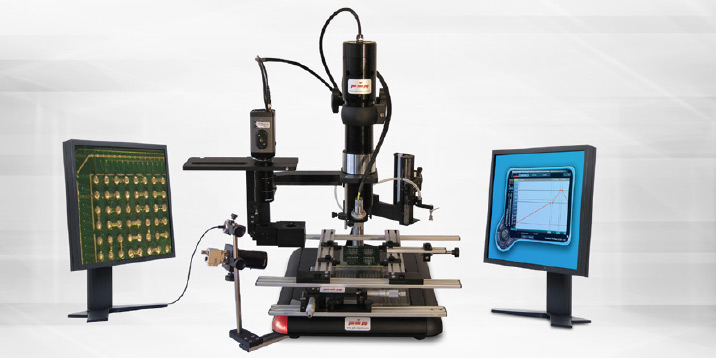

PCB Rework Tips in the end of SMT PCBA

PCB Rework After the PCBA inspection is completed, the defective PCBA needs to be repaired. The company has two methods for repairing the SMT PCBA. One is to use a constant temperature soldering iron (manual welding) for repair, and the other is to use a repair workben...Read more -

How to use solder paste in PCBA process?

How to use solder paste in PCBA process? (1) Simple method for judging the viscosity of solder paste: Stir the solder paste with a spatula for about 2-5 minutes, pick up a little solder paste with the spatula, and let the solder paste fall down naturally. The viscosity is moderate; if the solder...Read more