News

-

What Are The Requirements for PCB Board Press-fit Structure Design?

Multilayer PCB is mainly composed of copper foil, semi-cured sheet, core board. There are two types of press-fit structure, namely copper foil and core board press-fit structure and core board and core board press-fit structure. Preferred copper foil and core lamination structure, special plates ...Read more -

The Temperature and Humidity of PCB Board Storage and How to Store It?

with the development of electronic technology, circuit boards are widely used in various fields, almost all electronic devices have circuit boards. High-end automotive, aviation, medical electronics, common smart home, communication electronics, household appliances, etc. pcb board as a carrier o...Read more -

PCBA Thermal Pads Design Requirements

1. What is thermal pad The so-called thermal pads, refers to the bottom of the components with the metal side of the heat dissipation solder pads, usually relatively small power, mainly through the heat dissipation pads on the heat dissipation holes to the ground layer. In order to better heat di...Read more -

How to Improve The Production Efficiency of SMT Machine?

In the production line of SMT, the most important concern is often how to control production costs and improve production efficiency. This involves the problem of the SMT machine throwing rate. The high rate of SMD machine throwing material seriously affects the SMT production efficiency. If it i...Read more -

The 6 Steps of The Basic Process of Multilayer Circuit Board

The production method of multilayer boards is generally done by the inner layer graphics first, then by printing and etching method to make a single-sided or double-sided substrate, and into the designated layer between, and then by heating, pressing and bonding, as for the subsequent drilling is...Read more -

Reflow Oven Maintenance Methods and Precautions

Reflow Oven Maintenance Methods Before inspection, stop the reflow oven and lower the temperature to room temperature (20~30℃). 1. Clean the exhaust pipe:Clean the oil and dirt in the exhaust pipe with a cleaning cloth. 2. Clean dust and dirt from drive sprocket:Clean dust and dirt from drive spr...Read more -

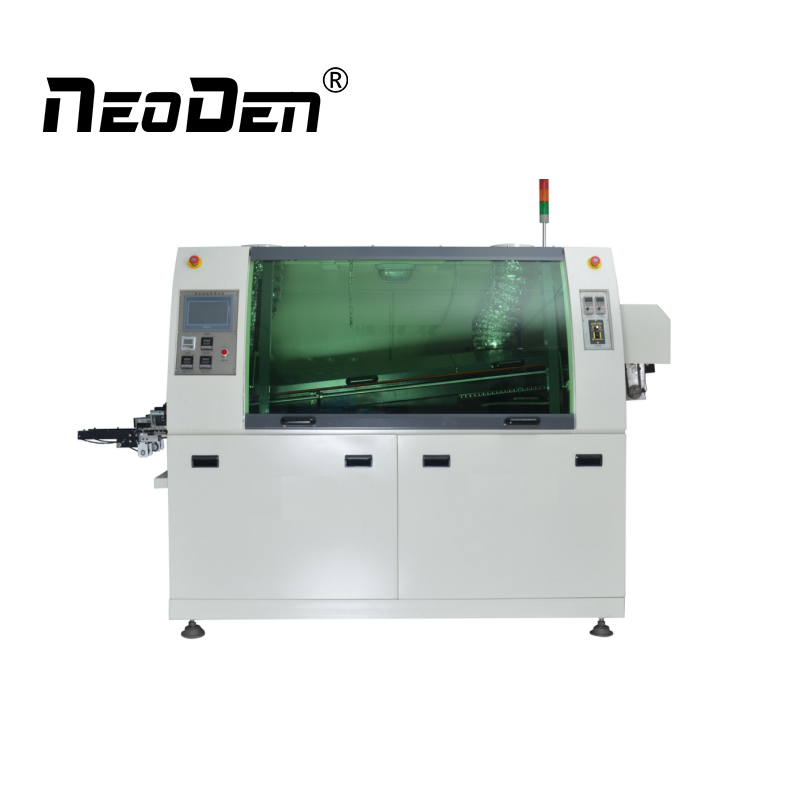

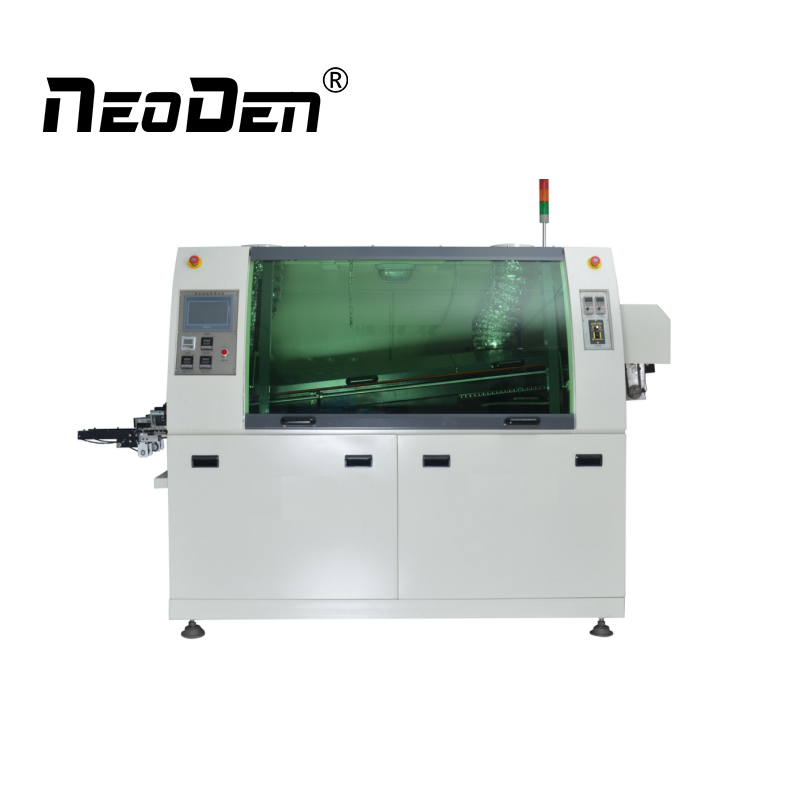

What are the daily checks required for wave soldering machine?

What are the daily checks required for wave soldering machine? Check the flux filter and remove any excess flux residue. The flux filter is cleaned with water once a week, the inside of the extraction hood is cleaned weekly and the spray system is checked for uniformity of spray. The nozzle shoul...Read more -

Analysis of The Causes of Continuous Soldering with Wave Soldering

1. inappropriate preheating temperature. Too low a temperature will cause poor activation of flux or PCB board and insufficient temperature, resulting in insufficient tin temperature, so that the liquid solder wetting force and fluidity becomes poor, adjacent lines between the solder joint bridge...Read more -

Reflow Oven Process Requirements

Reflow soldering machine technology is not new to the electronics manufacturing sector, as the components on the various boards used within our computers are soldered to the circuit boards using this process. The advantages of this process are that the temperature is easily controlled, oxidation ...Read more -

SMT Machine Components and Structure Overview

SMT machine is a machine – electrical – optical and computer control technology, is a precision work robot, it gives full play to modern precision machinery, mechanical and electrical integration, photoelectric combination, as well as computer control technology, high-tech achievement...Read more -

The principle, characteristics and application of electrode arc welding

1. Process principle Electrode arc welding is an arc welding method using a manually operated welding rod. The symbol mark E for electrode arc welding and the numerical mark 111. The welding process of electrode arc welding: when welding, the welding rod is brought into contact with the workpiece...Read more -

Tips on the correct use of reflow soldering machine

Reflow oven operation steps 1. Check that there is debris inside the equipment, do a good job of cleaning, to ensure safety, turn on the machine, select the production program to open the temperature settings. 2. Reflow oven guide width to be adjusted according to the width of the PCB, open the t...Read more