News

-

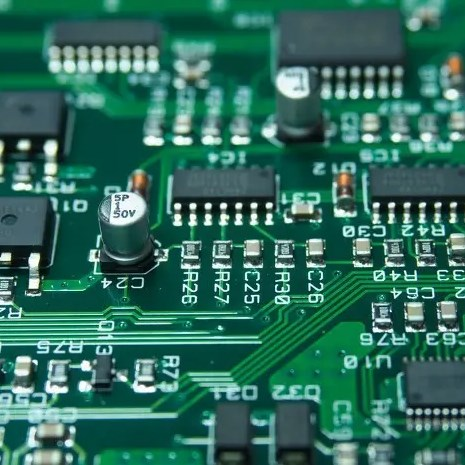

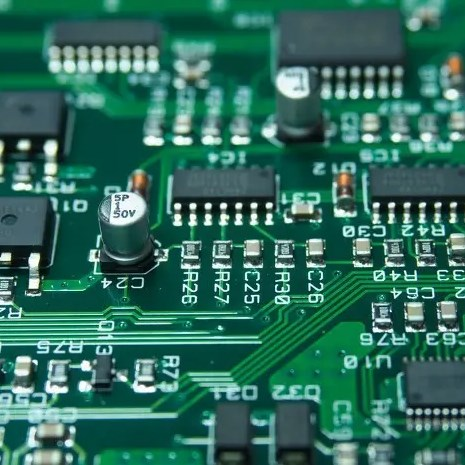

Why is component placement so important?

PCB design 90% in the device layout, 10% in the wiring, this is indeed a true statement. Starting to go to the trouble of placing the devices carefully can make a difference and improve the electrical characteristics of the PCB. If you just put the components on the board haphazardly, what will h...Read more -

What is the reason for the empty welding of the components?

SMD will have a variety of quality defects occur, for example, the component side of the warped empty solder, the industry called this phenomenon for the monument. One end of the component warped thus causing the monument empty solder, is a variety of reasons for the formation of. Today, we will ...Read more -

What are the BGA welding quality inspection methods?

How to determine the quality of BGA welding, with what equipment or what testing methods? The following to tell you about the BGA welding quality inspection methods in this regard. BGA welding unlike the capacitor-resistor or external pin class IC, you can see the quality of welding on the outsid...Read more -

What Factors Affect Solder Paste Printing?

The main factors that affect the filling rate of solder paste are printing speed, squeegee angle, squeegee pressure and even the amount of solder paste supplied. In simple terms, the faster the speed and the smaller the angle, the greater the force downward of the solder paste and the easier it i...Read more -

Requirements for layout design of reflow welded surface elements

Reflow soldering machine has a good process, there is no special requirements for the layout of components location, direction and spacing. Reflow soldering surface components layout mainly consider solder paste printing stencil open window to components spacing requirements, check and return to ...Read more -

Why the capacitor will stand monument false solder?

1.The problem of solder paste printing In the time of solder paste printing, because the solder paste printing is not flat, one end solder paste quantity is more, one end solder paste quantity is less, lead to reflow oven soldering hot melt appear time inconsistent, tension size is uneven, one en...Read more -

What is the role of PCB board printing solder paste?

SMD processing is a kind of electronic manufacturing services, called SMT. PCB is a kind of substrate components of PCBA, today to talk to you about the role of PCB board printing solder paste. Printed solder paste has two main roles. 1.Fixed electronic components Solder paste is similar to tooth...Read more -

How to solve the problem of excessive solder dross in wave soldering machine?

1. Slag check, check whether the tin furnace in the opening operation before a certain amount of tin slag, to promptly clean up the slag left before the last work, especially the wave motor area and wave flow channel mouth area. 2. Anti-oxidation wave soldering in the wave soldering machine nozzl...Read more -

How to increase the SMT machine placement accuracy?

SMT machine in the use will be according to our own program set operation steps for placement and production tasks, we in order to better let the SMT machine to carry out accurate placement, we need to mount the machine to adjust, mainly adjust the following 3 points. 1.Mounter placement calibrat...Read more -

The difference between laser welding and reflow soldering

Introduction to Reflow Oven The most obvious difference between reflow soldering machine and traditional wave soldering machine is that in traditional wave soldering the lower part of the PCB is completely immersed in the liquid solder, while in reflow soldering only some specific areas are in co...Read more -

What is the Feeder of the SMT machine?

SMT machine’s Feeder is generally translated as feeder or feeder. Its role is to pick SMD components mounted on the feeder, the feeder for the bonder to provide components for placement. For example, there is a PCB need to mount 10 kinds of components, then you need 10 feeders to install componen...Read more -

What are the key points of PCB wiring when anti-surge?

I. Pay attention to the size of the inrush current designed in the PCB wiring In the test, often encounter the original design of the PCB can not meet the needs of the surge. General engineers design, only take into account the functional design of the system, such as the actual work of the syste...Read more