News

-

AOI classification and structure principle in SMT production

With the wide application of 0201 chip components and 0.3 Pinch integrated circuit, enterprises have higher and higher requirements for product quality, which cannot be guaranteed by visual inspection alone. At this time, AOI technology arises at the right moment. As a new member of SMT productio...Read more -

Why do you need PCB cleaning?

First of all, I would like to introduce our PCB cleaning machine and steel mesh cleaning machine: PCB cleaning machine is brush roller single type cleaning machine. It is used between loader and Stencil printing machine, suitable for AI and SMT cleaning needs, can achieve the requirements of very...Read more -

What are the characteristics of reflow welding process?

Reflow flow welding refers to a welding process that realizes mechanical and electrical connections between solder ends or pins of surface assembly components and PCB solder pads by melting solder paste pre-printed on PCB solder pads. 1. Process flow Process flow of reflow soldering: printing sol...Read more -

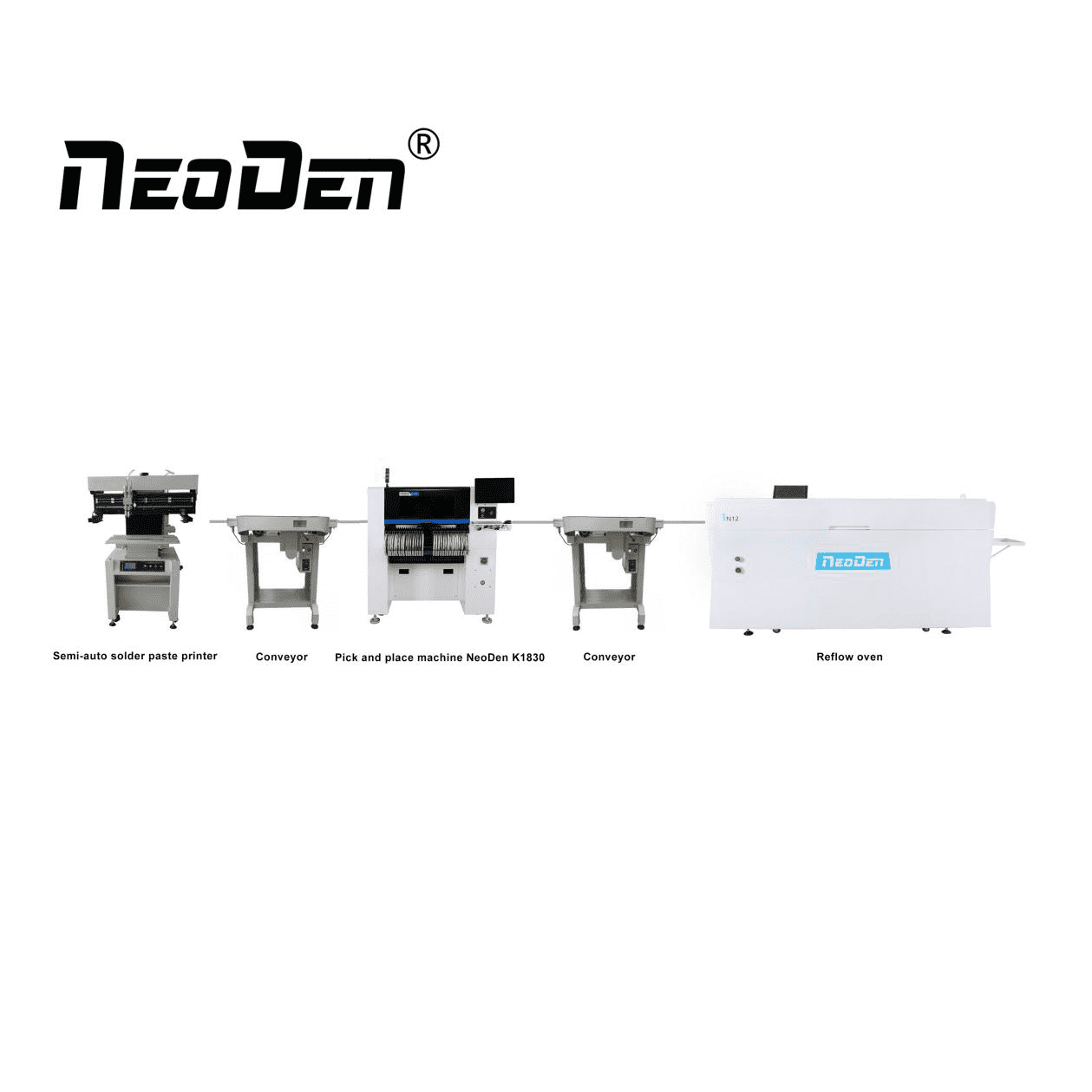

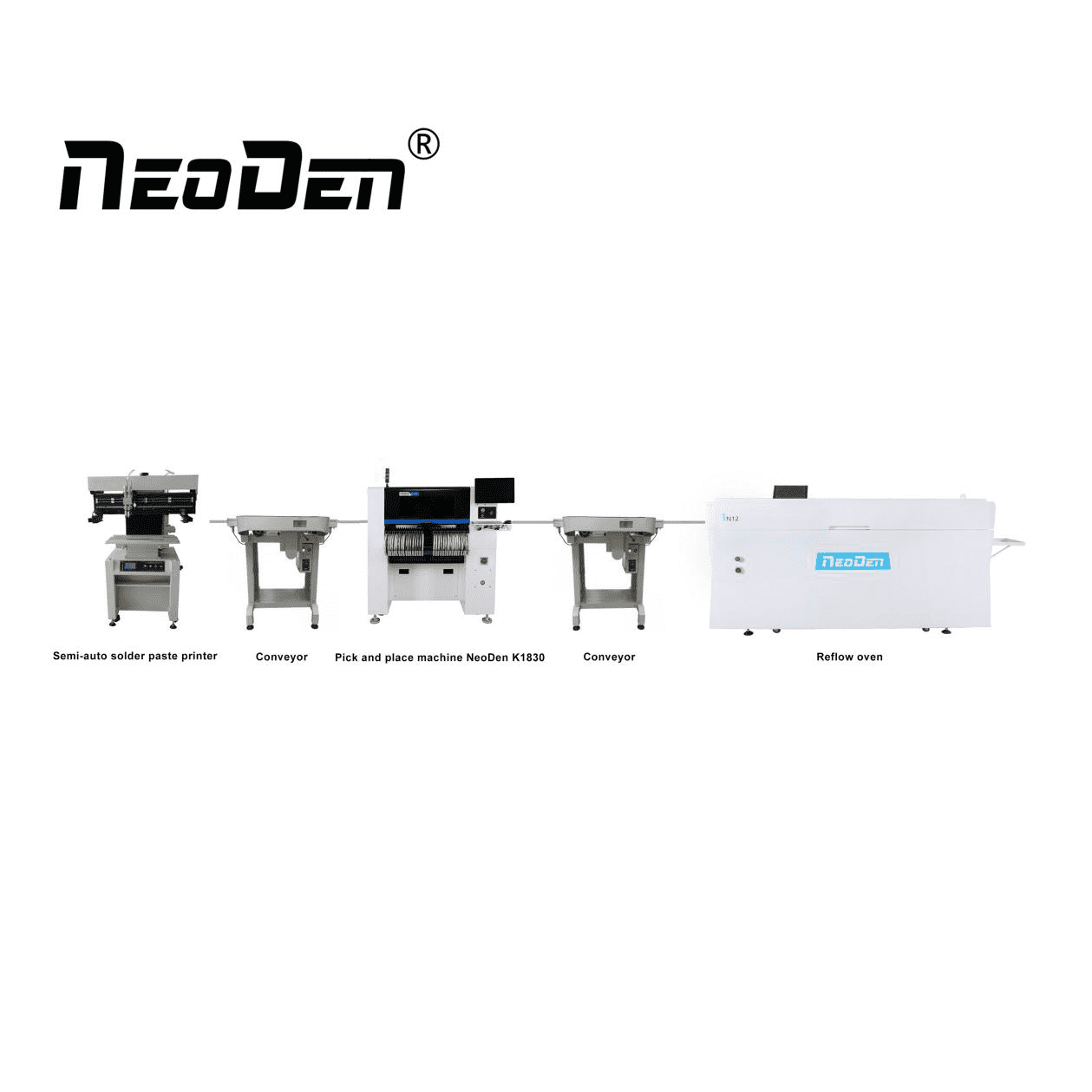

What equipment and functions are needed for PCBA production?

PCBA production requires basic equipment such as SMT soldering paste printer, SMT machine, reflow oven, AOI machine, component pin shearing machine, wave soldering, tin furnace, plate washing machine, ICT test fixture, FCT test fixture, aging test rack, etc. PCBA processing plants of different si...Read more -

What points should be paid attention to in SMT chip processing?

1.Storage condition of solder paste Solder paste must be applied to SMT patch processing. If the solder paste is not applied immediately, it must be placed in a natural environment of 5-10 degrees, and the temperature must not be less than 0 degrees or higher than 10 degrees. 2.Daily maint...Read more -

Solder Paste mixer Installation and use

We recently launched a solder paste mixer, the installation and use of solder paste machine will be briefly described below. After purchasing the product, we will provide you with a more complete product description. Please feel free to contact us if you need it. Thank you. 1.Please put the mach...Read more -

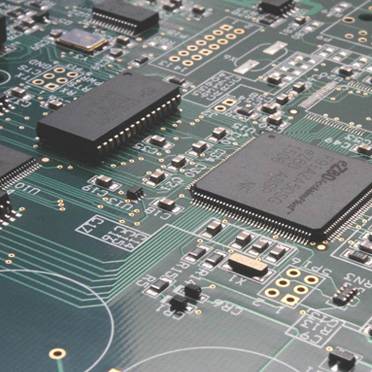

17 requirements for component layout design in SMT process(II)

11. Stress-sensitive components should not be placed at the corners, edges, or near connectors, mounting holes, grooves, cutouts, gashes and corners of printed circuit boards. These locations are high stress areas of printed circuit boards, which can easily cause cracks or cracks in solder joints...Read more -

SMT Machine Safety Precautions

Clean the net stipulation uses the cloth to touch the alcohol to clean, cannot pour the alcohol directly to the steel net and so on. It is required to go to the new program to check the position of the scraper printing stroke each time. Both sides of the y-direction scraper stroke should exceed ...Read more -

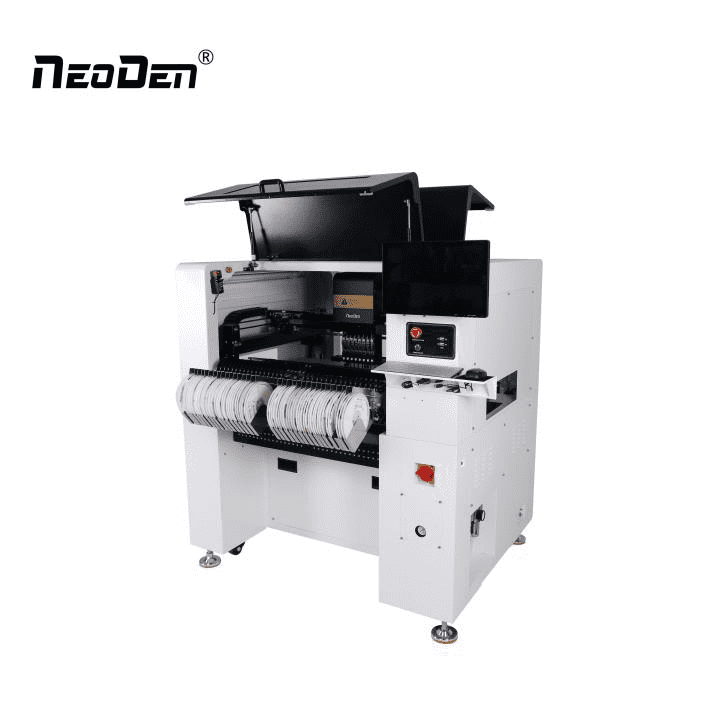

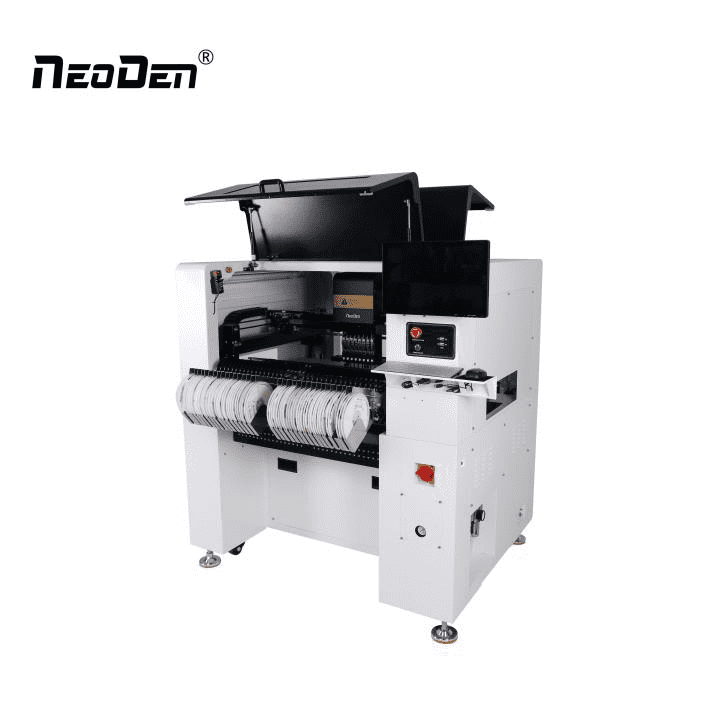

Role and selection of air compressor for SMT Placement Machine

SMT pick and place machine also known as “placement machine” and “surface placement system”, is a device for placing surface placement components accurately on THE PCB solder plate by moving the placement head after dispensing machine or stencil printer in the production l...Read more -

SMT AOI machine location on SMT production line

While SMT AOI machine can be used at multiple locations on the SMT production line to detect specific defects, AOI inspection equipment should be placed in a location where the most defects can be identified and corrected as early as possible. There are three main check locations: After the solde...Read more -

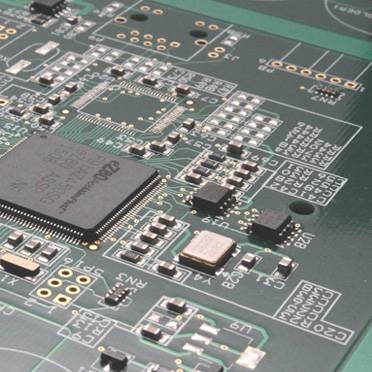

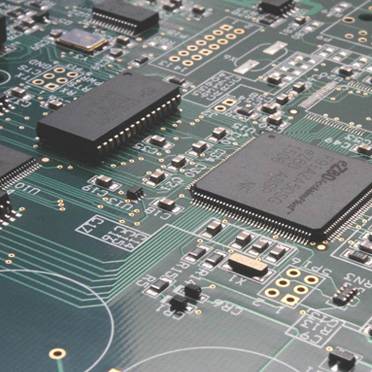

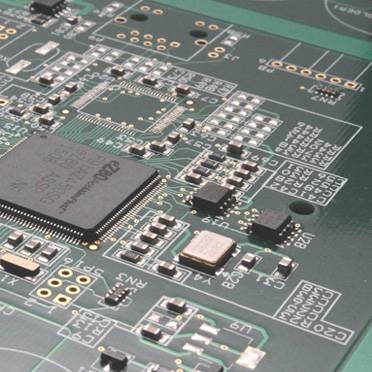

17 requirements for component layout design in SMT process(I)

1. The basic requirements of SMT process for component layout design are as follows: The distribution of the components on the printed circuit board should be as uniform as possible. The heat capacity of reflow soldering of large quality components is large, and excessive concentration is easy to...Read more -

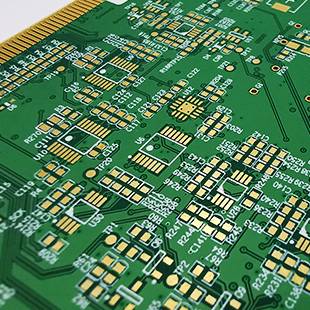

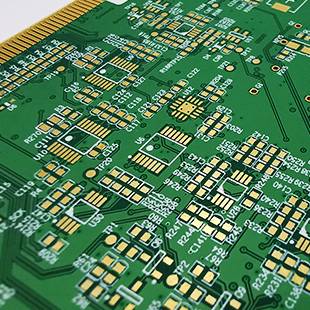

How does PCB factory control PCB board quality

Quality is the survival of an enterprise, if the quality control is not in place, the enterprise will not go far, PCB factory if you want to control the quality of PCB board, then how to control? We want to control the quality of PCB board, there must be a quality control system, is often said to...Read more