News

-

110 knowledge points of SMT chip processing – Part 1

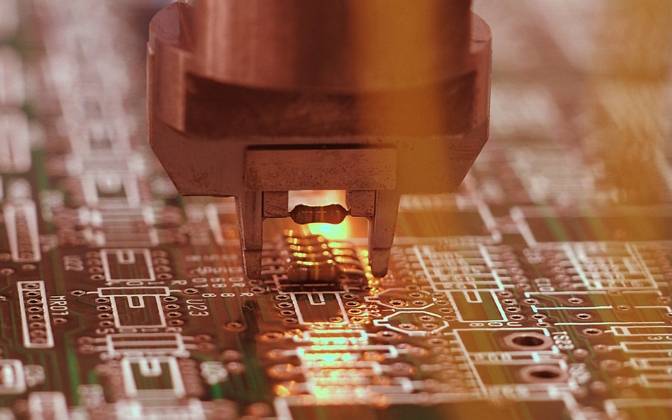

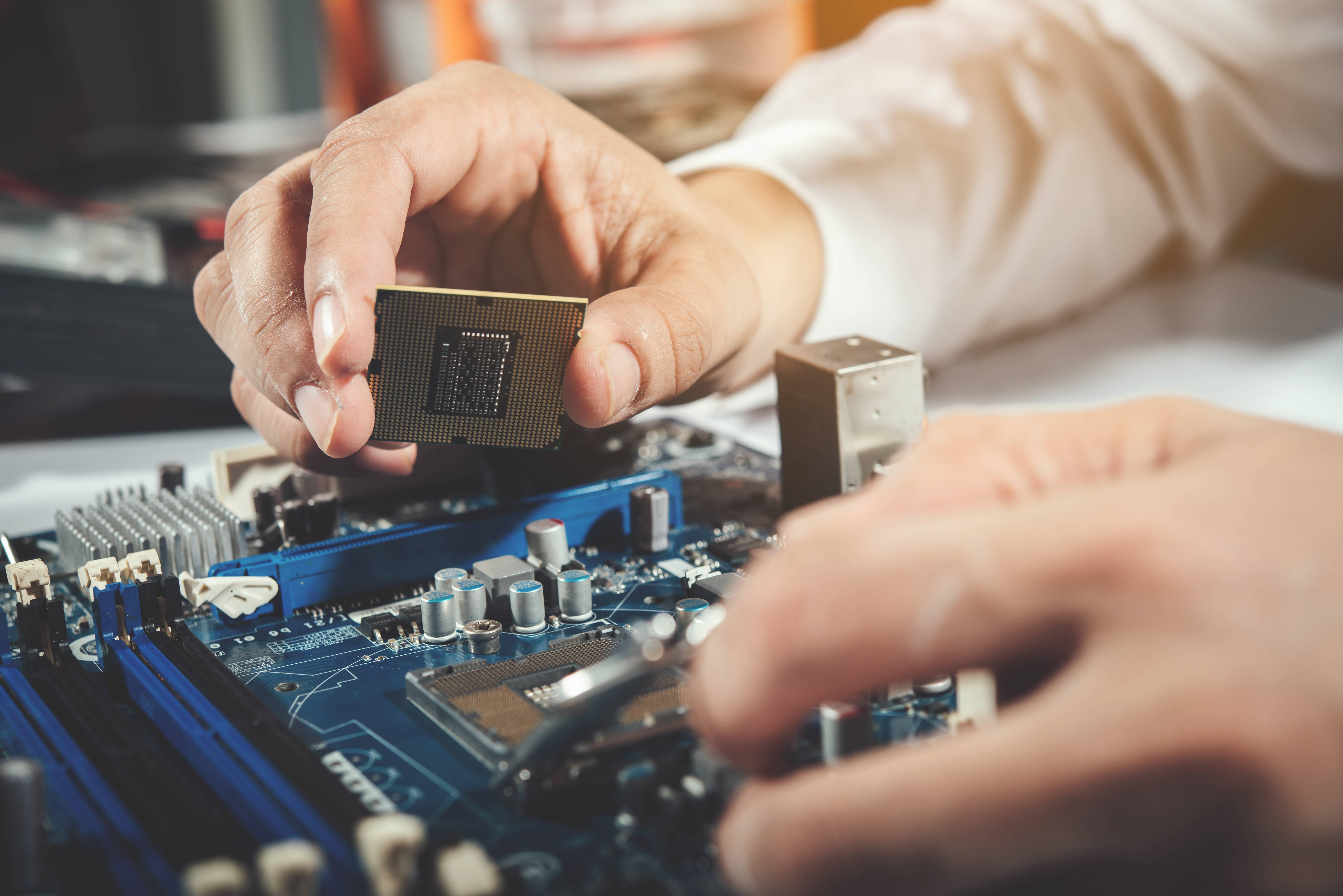

110 knowledge points of SMT chip processing – Part 1 1. Generally speaking, the temperature of SMT chip processing workshop is 25 ± 3 ℃; 2. Materials and things needed for solder paste printing, such as solder paste, steel plate, scraper, wiping paper, dust-free paper, detergent and mixing ...Read more -

Temperature and humidity requirements and management methods of SMT workshop

Temperature and humidity requirements and management methods of SMT workshop There are clear requirements for temperature and humidity in SMT workshop. The importance of SMT for SMT will not be discussed here. Some time ago, 00 science and Technology Group invited our factory to improve the tempe...Read more -

What is Bridging

Bridging Bridge connection is one of the common defects in SMT production. It will cause short circuit between components, and it must be repaired when it meets bridge connection. There are many reasons for bridge connection 1) Quality problems of solder paste ① The metal content in solder paste ...Read more -

Some common problems and solutions in soldering

Foaming on PCB substrate after SMA soldering The main reason for the appearance of nail size blisters after SMA welding is also the moisture entrained in the PCB substrate, especially in the processing of multilayer boards. Because the multilayer board is made of multi-layer epoxy resin prepreg a...Read more -

The factors affecting the quality of reflow soldering

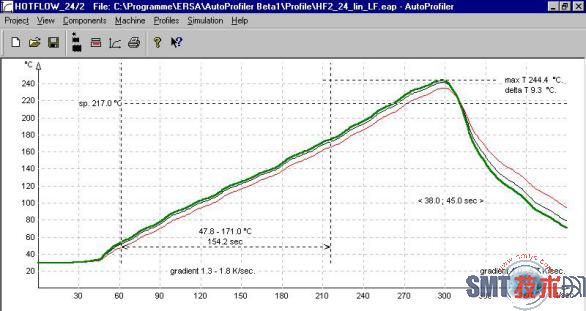

The factors affecting the quality of reflow soldering are as follows 1. Influencing factors of solder paste The quality of reflow soldering is affected by many factors. The most important factor is the temperature curve of reflow furnace and the composition parameters of solder paste. Now the c...Read more -

SMT quality analysis

The common quality problems of SMT work including missing parts, side pieces, turnover parts, deviation, damaged parts, etc. 1. The main causes of patch leakage are as follows: ① The feeding of component feeder is not in place. ② The air path of the component suction nozzle is blocked, the suctio...Read more -

What is AOI

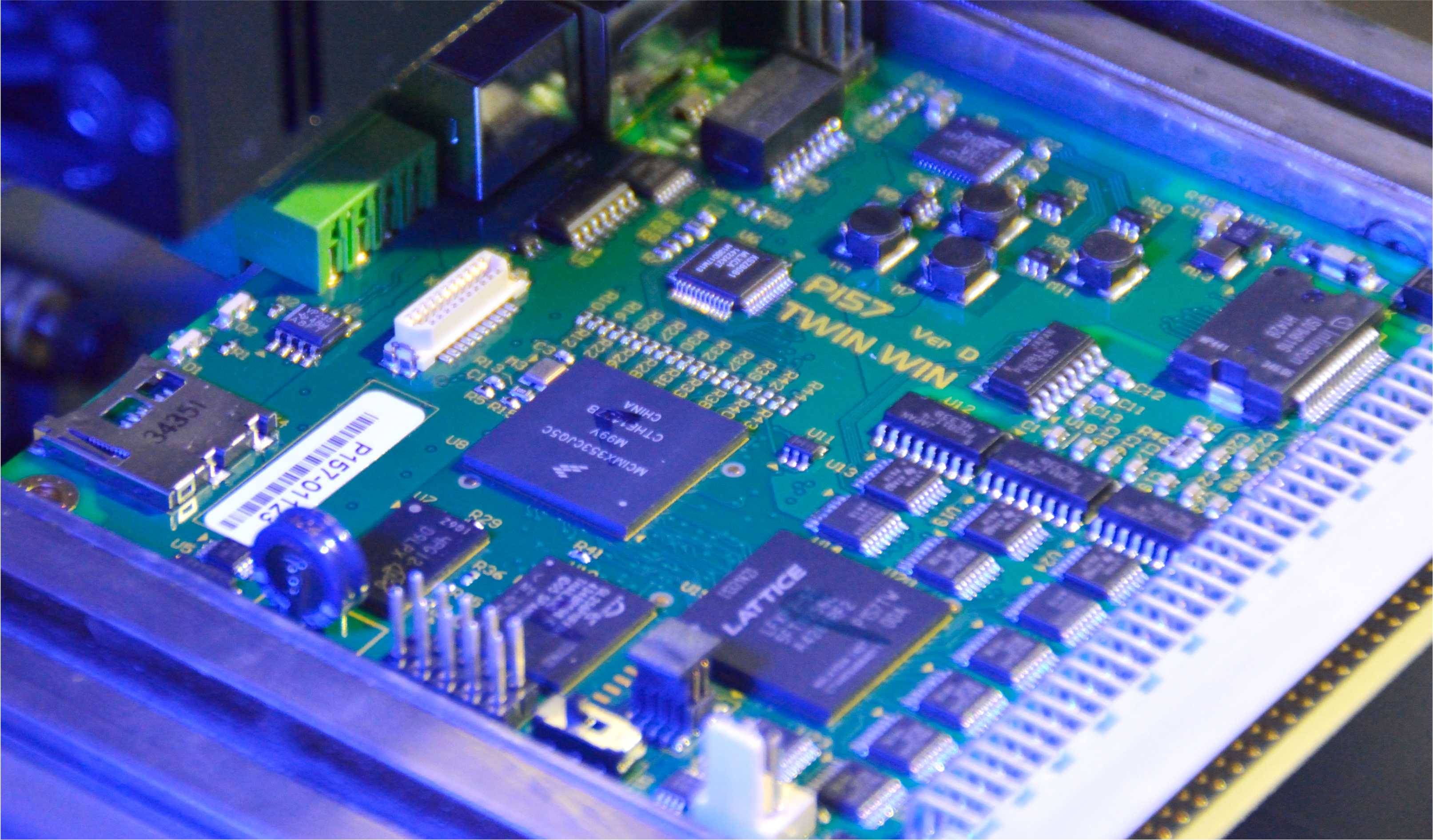

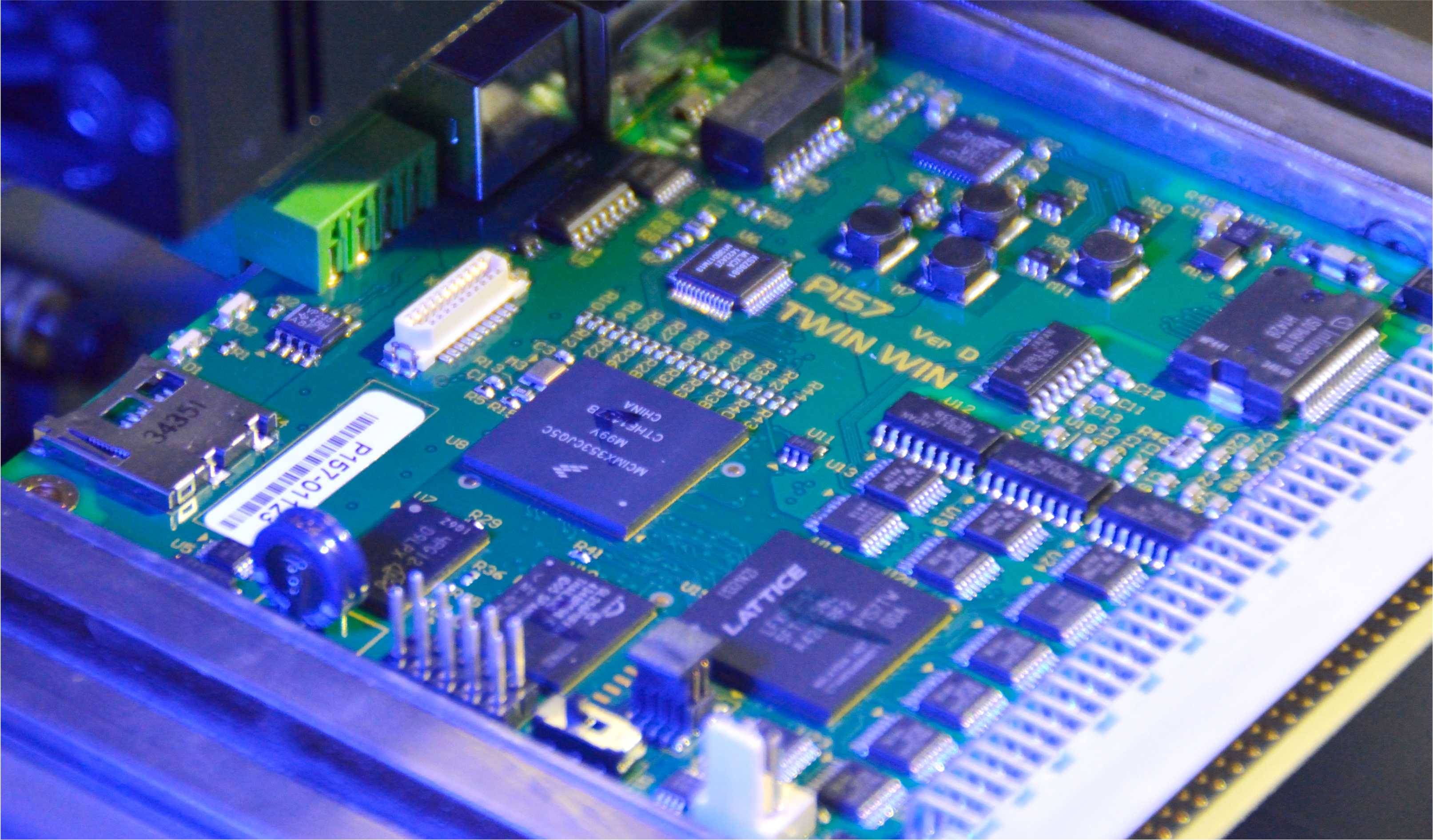

What is AOI testing technology AOI is a new type of testing technology which has been rising rapidly in recent years. At present, many manufacturers have launched AOI test equipment. When automatic detection, the machine automatically scans PCB through the camera, collects images, compares the te...Read more -

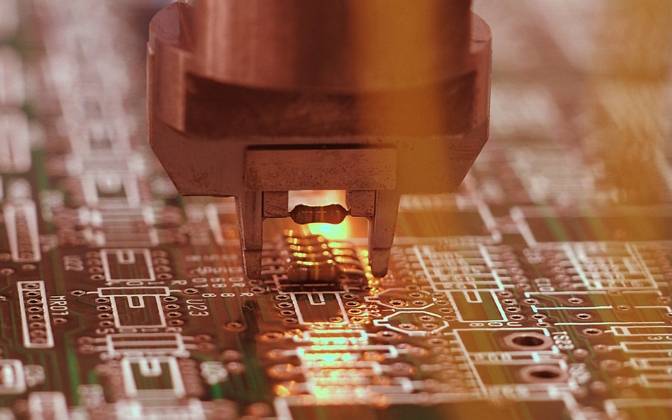

The difference between laser welding and selective wave soldering

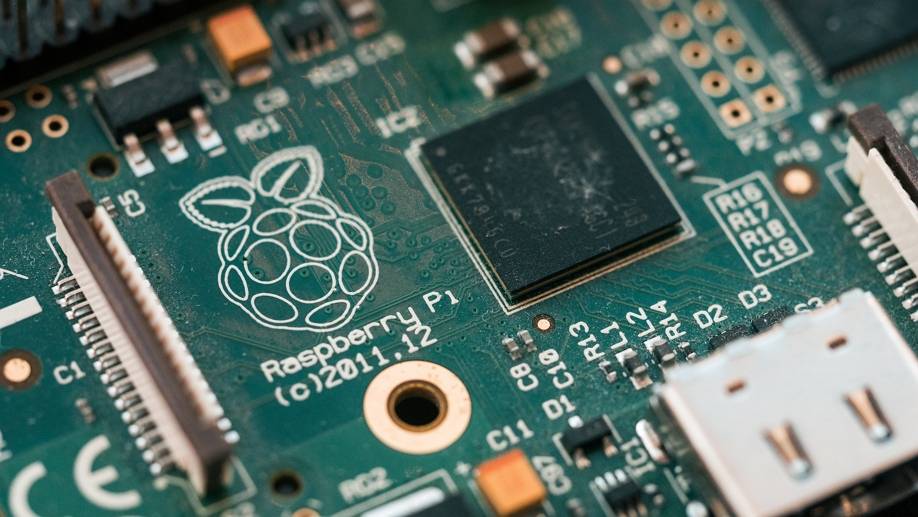

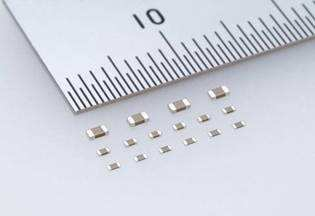

As all kinds of electronic products are beginning to be miniaturized, the application of traditional welding technology to various new electronic components has certain tests. In order to cater to such market demand, among the welding process technology, it can be said that the technology is cont...Read more -

Function analysis of various SMT appearance inspection equipment AOI

a) : Used to measure the solder paste printing quality inspection machine SPI after the printing machine: SPI inspection is carried out after the solder paste printing, and defects in the printing process can be found, thereby reducing the soldering defects caused by poor solder paste printing to...Read more -

SMT testing equipment application and development trend

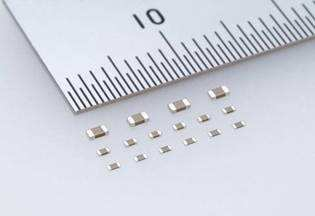

With the development trend of the miniaturization of SMD components and the higher and higher requirements of the SMT process, the electronic manufacturing industry has higher and higher requirements for testing equipment. In the future, SMT production workshops should have more testing equipment...Read more -

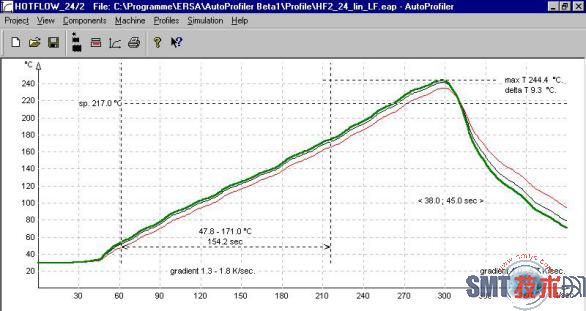

How to setting of furnace temperature curve?

At present, many advanced electronic product manufacturers at home and abroad have proposed a new equipment maintenance concept “synchronous maintenance” in order to further reduce the impact of maintenance on production efficiency. That is, when the reflow oven is working at full cap...Read more -

Requirements for lead-free reflow oven equipment materials and construction

l Lead-free high temperature requirements for equipment materials Lead-free production requires equipment to withstand higher temperatures than leaded production. If there is a problem with the equipment material, a series of problems such as furnace cavity warpage, track deformation, and poor se...Read more