News

-

Requirements for lead-free reflow oven equipment materials and construction

l Lead-free high temperature requirements for equipment materials Lead-free production requires equipment to withstand higher temperatures than leaded production. If there is a problem with the equipment material, a series of problems such as furnace cavity warpage, track deformation, and poor se...Read more -

The two points of controlling wind speed for reflow oven

In order to realize the control of wind speed and air volume, two points need to be paid attention to: The speed of the fan should be controlled by frequency conversion to reduce the influence of voltage fluctuation on it; Minimize the exhaust air volume of the equipment, because the central loa...Read more -

What new requirements does the increasingly mature lead-free process put on the reflow oven?

What new requirements does the increasingly mature lead-free process put on the reflow oven? We analyze from the following aspects: l How to obtain a smaller lateral temperature difference Since the lead-free soldering process window is small, the control of the lateral temperature difference is...Read more -

The increasingly mature lead-free technology requires reflow soldering

According to the EU’s RoHS Directive (Directive Act of the European Parliament and the Council of the European Union on the restriction of the use of certain hazardous substances in electrical and electronic equipment), The directive requires the ban on the EU market to sell electronic and ...Read more -

Solder paste printing solution for miniaturized components 3-3

1) Electroforming stencil The manufacturing principle of the electroformed stencil: the electroformed template is made by printing the photoresist material on the conductive metal base plate, and then through the masking mold and ultraviolet exposure, and then the thin template is electroformed i...Read more -

Solder paste printing solution for miniaturized components 3-2

To understand the challenges brought by miniaturized components to solder paste printing, we must first understand the area ratio of stencil printing (Area Ratio). For the solder paste printing of miniaturized pads, the smaller the pad and the stencil opening, the more difficult it is for the so...Read more -

Solder paste printing solution for miniaturized components 3-1

In recent years, with the increase in the performance requirements of smart terminal devices such as smart phones and tablet computers, the SMT manufacturing industry has a stronger demand for miniaturization and thinning of electronic components. With the rise of wearab...Read more -

Selective Soldering Oven Inside System

1. Flux spraying system Selective wave soldering adopts a selective flux spraying system, that is, after the flux nozzle runs to the designated position according to the programmed instructions, only the area on the circuit board that needs to be soldered is sprayed wit...Read more -

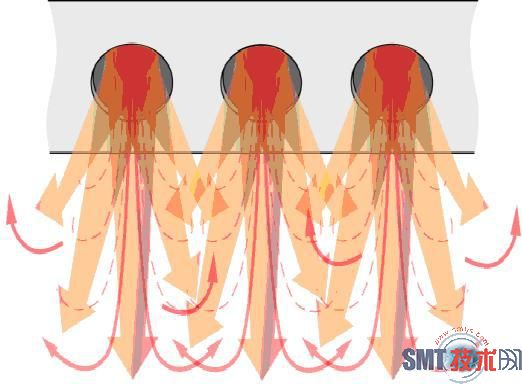

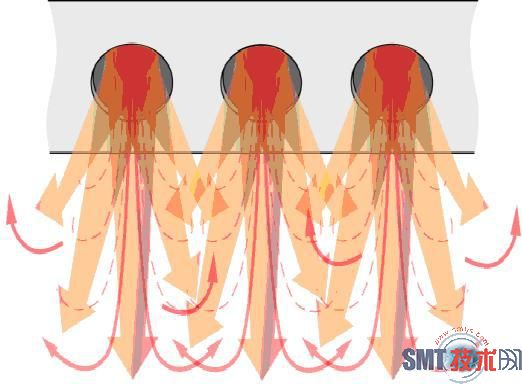

Reflow soldering principle

The reflow oven is used to solder the SMT chip components to the circuit board in the SMT process soldering production equipment. The reflow oven relies on the hot air flow in the furnace to brush the solder paste on the solder joints of the solder paste circuit b...Read more -

WAVE SOLDERING DEFECTS

Incomplete Joints on a Printed Circuit Board-WAVE SOLDERING DEFECTS The incomplete solder fillet is often seen on single-sided boards after wave soldering. In Figure 1, the lead-to-hole ratio is excessive, which has made soldering difficult. There is also evidence of resin smear on the edg...Read more -

SMT basic knowledge

SMT basic knowledge 1. Surface Mount Technology-SMT (Surface Mount Technology) What is SMT: Generally refers to the use of automatic assembly equipment to directly attach and solder chip-type and miniaturized leadless or short-lead surface assembly components/devices (...Read more -

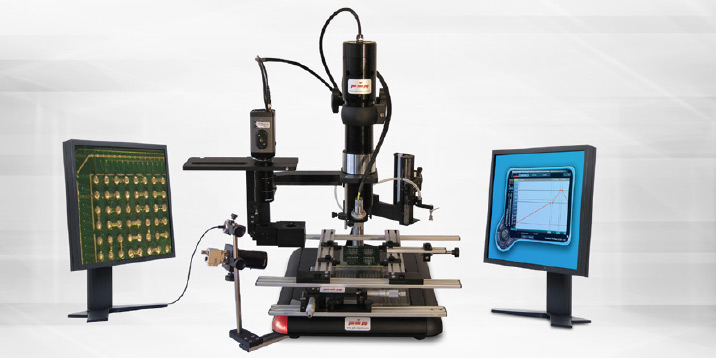

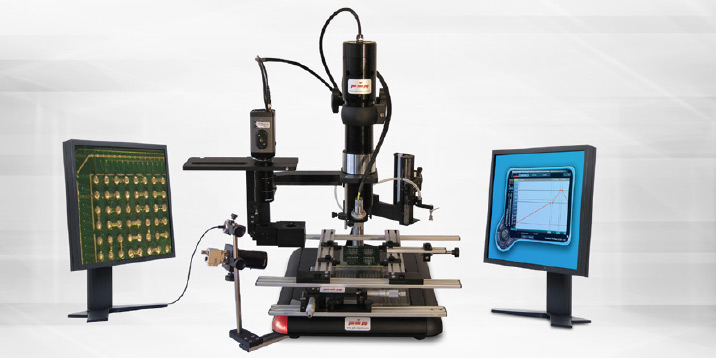

PCB Rework Tips in the end of SMT PCBA

PCB Rework After the PCBA inspection is completed, the defective PCBA needs to be repaired. The company has two methods for repairing the SMT PCBA. One is to use a constant temperature soldering iron (manual welding) for repair, and the other is to use a repair workben...Read more