News

-

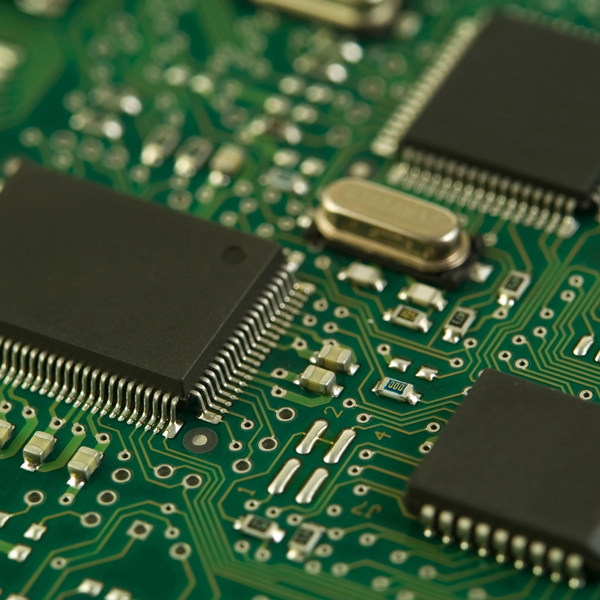

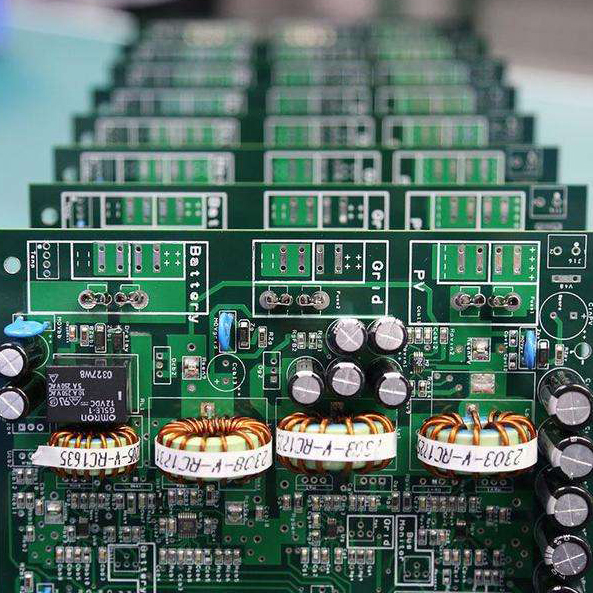

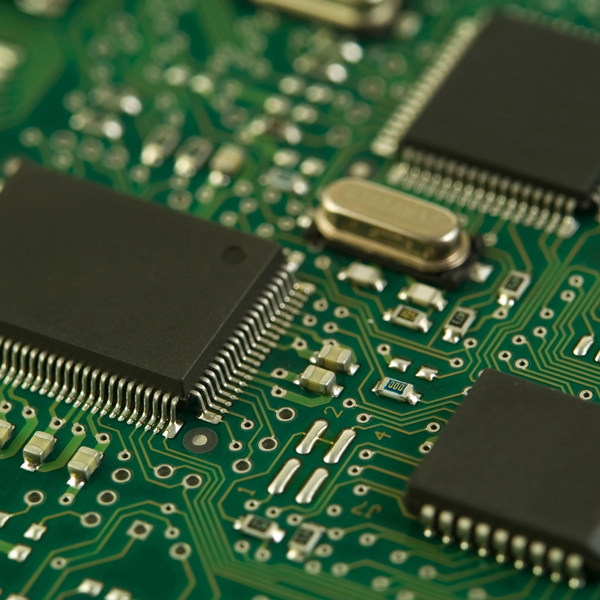

What Are The Causes of SMT Component Drop?

PCBA production process, due to a number of factors will lead to the occurrence of component drop, then many people will immediately think that may be due to the PCBA welding strength is not enough to cause. Component drop and welding strength has a very strong relationship, but many other reason...Read more -

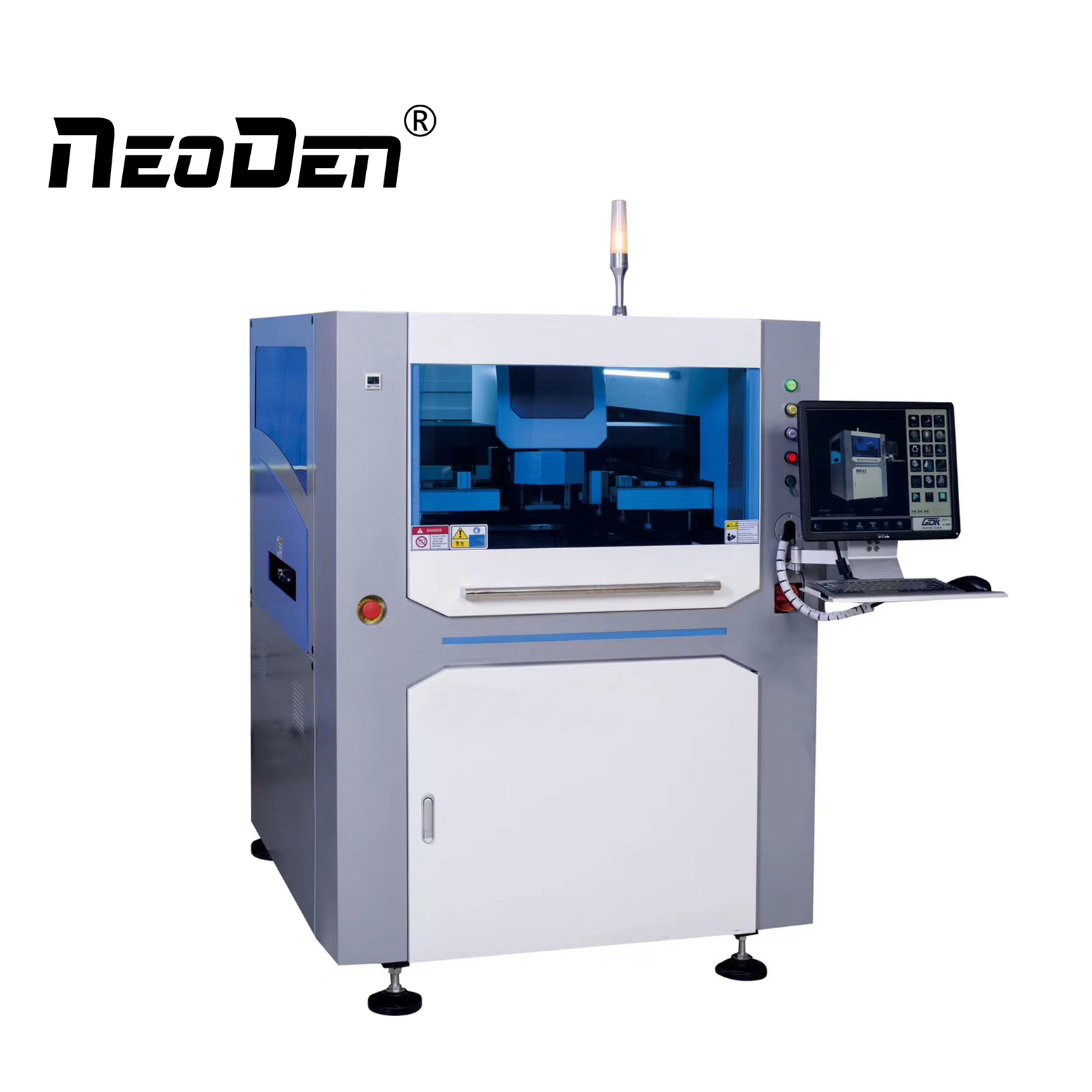

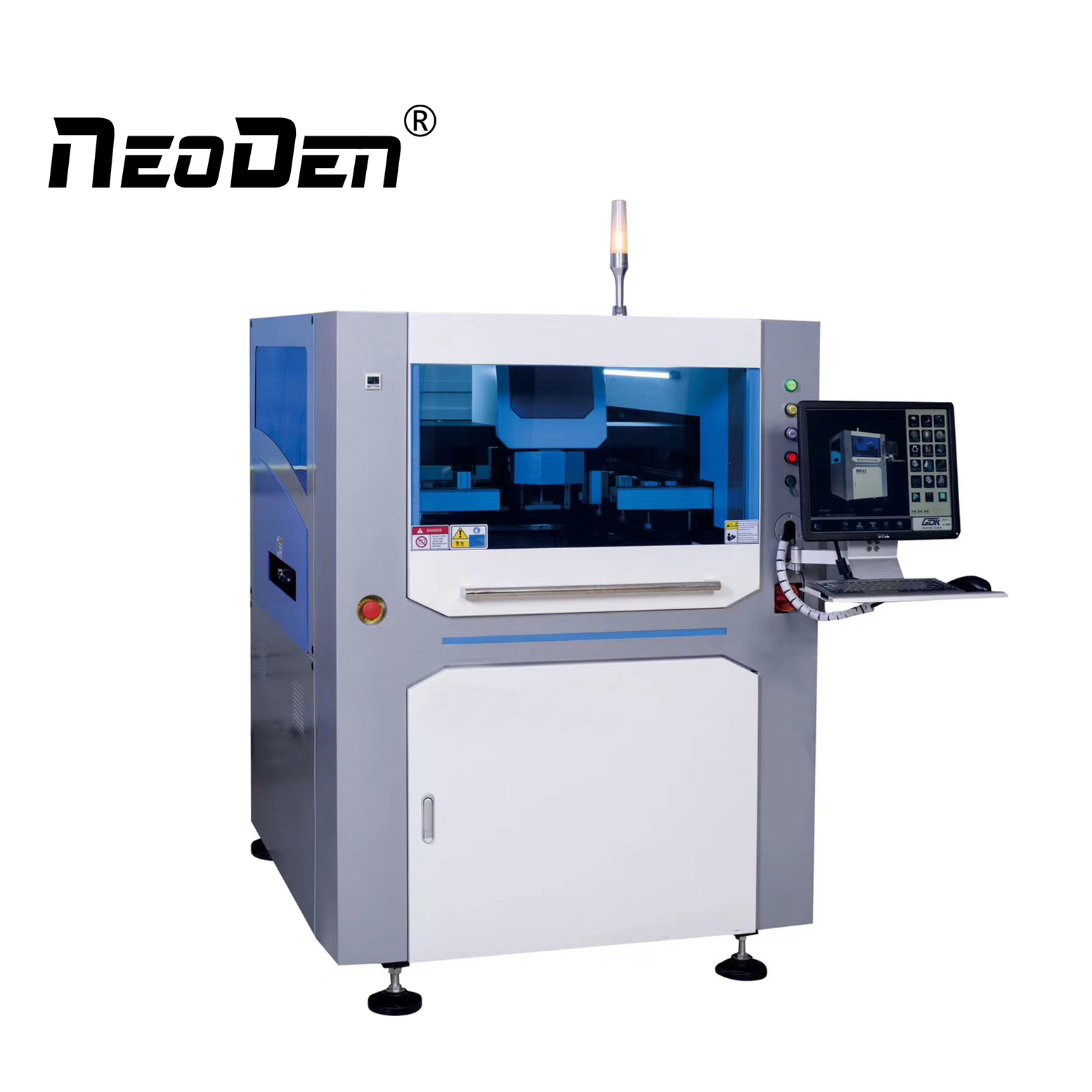

What Does A Stencil Printer Do?

I. Stencil printer types 1. Manual Stencil Printer A manual printer is the simplest and cheapest printing system. PCB placement and removal is done manually, the squeegee can be used by hand or attached to the machine, and the printing action is done manually. PCB and steel plate parallelism alig...Read more -

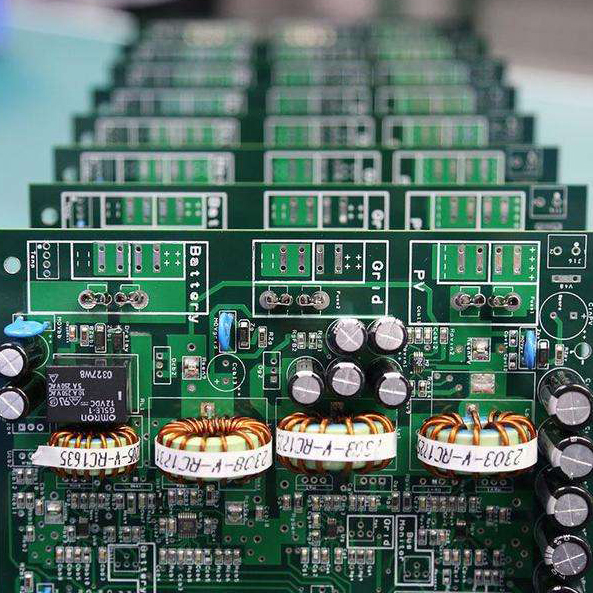

Soldering Techniques for Double-sided PCB

Double-sided circuit board characteristics Single-sided circuit board and double-sided circuit board in the difference is the number of layers of copper is different. Double-sided circuit board is the board on both sides of the copper, can be through the hole to play a connecting role. Single-sid...Read more -

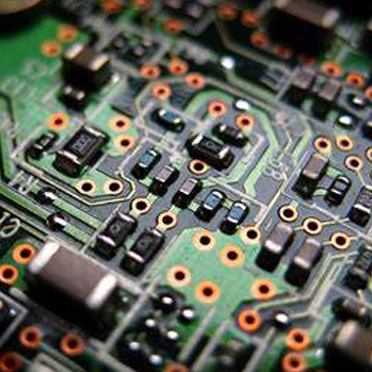

The Nine Basic Principles of SMB Design (II)

5. the choice of components The choice of components should take full account of the actual area of the PCB, as far as possible, the use of conventional components. Do not blindly pursue small size components to avoid increasing costs, IC devices should pay attention to the pin shape and foot spa...Read more -

The Nine Basic Principles of SMB Design (I)

1. Component layout Layout is in accordance with the requirements of the electrical schematic and the size of the components, the components are evenly and neatly arranged on the PCB, and can meet the mechanical and electrical performance requirements of the machine. Layout reasonable or not not ...Read more -

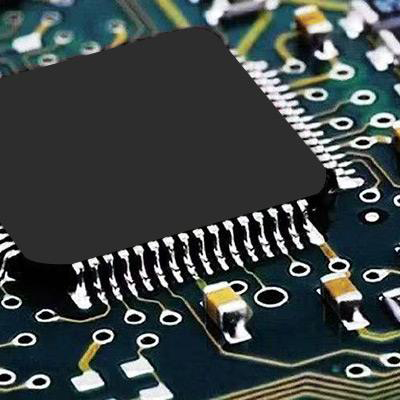

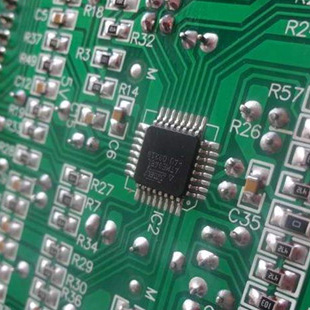

The Importance of SMT Placement Processing Through Rate

SMT placement processing, through rate is called the lifeline of the placement processing plant, some companies must reach 95% through rate is up to standard line, so through rate of high and low, reflecting the technical strength of the placement processing plant, process quality, through rate c...Read more -

What Are the Configuration and Considerations in COFT Control Mode?

LED driver chip introduction with the rapid development of the automotive electronics industry, high-density LED driver chips with wide input voltage range are widely used in automotive lighting, including exterior front and rear lighting, interior lighting and display backlighting. LED driver ch...Read more -

What Are The Technical Points of Selective Wave Soldering?

Flux spraying system Selective wave soldering machine flux spraying system is used for selective soldering, i.e. the flux nozzle runs to the designated position according to the pre-programmed instructions and then only fluxes the area on the board that needs to be soldered (spot spraying and lin...Read more -

14 Common PCB Design Erors and Reasons

1. PCB no process edge, process holes, can not meet the SMT equipment clamping requirements, which means that it can not meet the requirements of mass production. 2. PCB shape alien or size too large, too small, the same can not meet the requirements of equipment clamping. 3. PCB, FQFP pads aroun...Read more -

How to Maintain The Solder Paste Mixer?

The solder paste mixer can effectively mix the solder powder and flux paste. The solder paste is removed from the refrigerator without the need to reheat the paste, eliminating the need for reheating time. The water vapor also dries naturally during the mixing process, reducing the chance of abso...Read more -

Chip Component Pad Design Defects

1. 0.5mm pitch QFP pad length is too long, causing short circuit. 2. PLCC socket pads are too short, resulting in false soldering. 3. Pad length of IC is too long and the amount of solder paste is large causing short circuit at reflow. 4. Wing chip pads are too long affecting heel solder filling ...Read more -

The Discovery of PCBA Virtual Soldering Problem Method

I. The common reasons for the generation of false solder are 1. Solder melting point is relatively low, the strength is not large. 2. The amount of tin used in welding is too small. 3. Poor quality of the solder itself. 4. Component pins exist stress phenomenon. 5. Components generated by the hig...Read more